في عالم رفع الأحمال الثقيلة, غالبًا ما يقف اثنان من القويتين جنبًا إلى جنب في ورش العمل, المستودعات, ومواقع البناء: الرافعة الكهربائية ورافعة السلسلة اليدوية (غالبًا ما يسمى ببساطة رافعة سلسلة أو كتلة سلسلة). بينما يخدم كلاهما الغرض الأساسي من الرفع الرأسي, عملهم, القدرات, وتختلف التطبيقات المثالية بشكل كبير. يمكن أن يعني اختيار الخطأ عدم الكفاءة, تعب المشغل, أو حتى القوة غير الكافية. دعنا نتحطم الاختلافات الرئيسية.

الدردشة عبر الإنترنت

1. مصدر الطاقة & عملية:

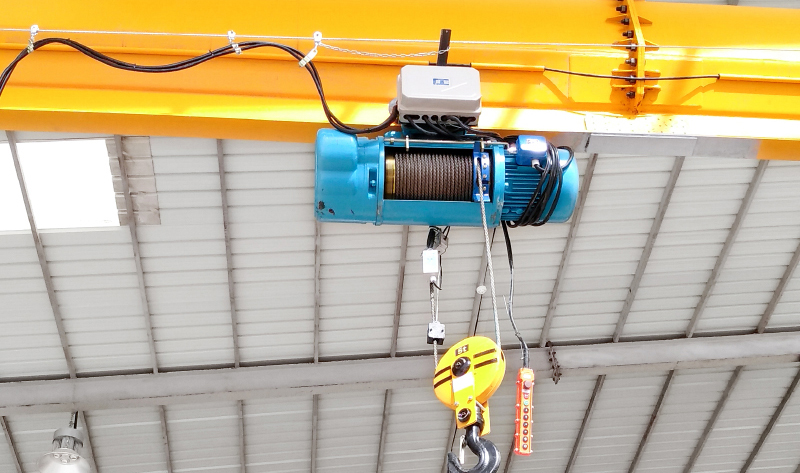

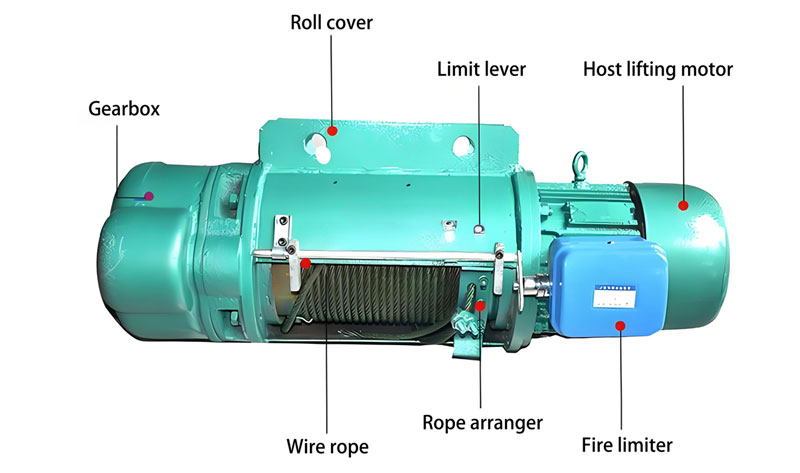

الرافعة الكهربائية: مدعوم بمحرك كهربائي. عادة ما تكون العملية عن طريق التحكم في قلادة الدفع (صعودا/لأسفل) أو في بعض الأحيان جهاز التحكم عن بُعد. يتطلب مصدر طاقة كهربائي موثوق (مرحلة واحدة أو ثلاث مراحل, اعتمادا على النموذج).

رافعة سلسلة: مدعوم من الجهد البشري بحت. يقوم المشغل بسحب سلسلة اليد في اتجاه واحد للرفع والاتجاه الآخر لخفض الحمل. لا حاجة الكهرباء.

2. سرعة رفع & كفاءة:

الرافعة الكهربائية: سرعات رفع وخفض أسرع. مثالي لمهام الرفع المتكررة, العمليات عالية الحجم, أو نقل الأحمال على مسافات أكبر بسرعة. يعزز الإنتاجية بشكل كبير.

رافعة سلسلة: سرعة رفع بطيئة نسبيا, يعتمد كليًا على قوة المشغل والقدرة على التحمل. الأنسب للمصاعد العرضية, تحديد موقع دقيق, أو مهام التردد المنخفضة. يمكن أن يسبب تعبًا للمشغل مع الاستخدام الثقيل أو المتكرر.

3. قدرة الرفع:

الرافعة الكهربائية: متوفر في مجموعة واسعة من القدرات, من الخفيفة (على سبيل المثال, 250 كجم / 0.25 طن) إلى نماذج شاقة للغاية (50 طن+). يتعامل بسهولة مع القدرات الأكبر بكفاءة.

رافعة سلسلة: متوفر أيضًا في مجموعة واسعة من القدرات (على سبيل المثال, 500 كجم ل 20 طن+ مشترك). لكن, غالبًا ما تقتصر القدرة العملية على قدرة المشغل على سحب السلسلة بشكل فعال, خاصة بالقرب من تصنيف الرافعة القصوى. تتطلب النماذج ذات السعة العالية جدًا جهدًا هائلاً.

4. يتحكم & دقة:

الرافعة الكهربائية: يوفر تحكمًا جيدًا عبر المحركات المتغيرة السرعة (على العديد من النماذج) لبدء/توقفات سلسة وتحديد المواقع. أسهل في العمل باستمرار. لكن, قد يتطلب التحكم "بوصة" الدقيق ميزات محددة.

رافعة سلسلة: يوفر ملاحظات ممتازة عن طريق اللمس والتحكم الدقيق جدًا لتحديد المواقع الدقيقة (على سبيل المثال, الآلات المناسب, محاذاة المكونات). يشعر المشغل مباشرة بالحمل.

5. تثبيت & متطلبات:

الرافعة الكهربائية: يتطلب الأسلاك الكهربائية المناسبة وغالبًا ما يكون بنية داعمة قوية (شعاع, عربة, القنوات) بسبب ارتفاع السرعات والقوى الديناميكية المحتملة. التثبيت أكثر تعقيدًا بشكل عام ويتطلب أفراد مؤهلين.

رافعة سلسلة: تثبيت أبسط. في المقام الأول يحتاج إلى نقطة مرساة مناسبة (خطاف, العروة) على شعاع أو بنية. محمول للغاية - نقل بسهولة إلى مواقع مختلفة.

6. اعتبارات التكلفة:

الرافعة الكهربائية: ارتفاع تكلفة الشراء الأولية. يتطلب التكاليف الكهربائية المستمرة. احتمال ارتفاع تكاليف الصيانة بسبب المحرك, علبة التروس, والمكونات الكهربائية.

رافعة سلسلة: انخفاض تكلفة الشراء الأولية. لا تكاليف طاقة التشغيل (ما وراء السعرات الحرارية المشغل!). بشكل عام أقل من تكاليف الصيانة (التروس, المحامل, سلسلة).

7. ضوضاء & بيئة:

الرافعة الكهربائية: يولد ضوضاء من المحرك وصندوق التروس أثناء التشغيل.

رافعة سلسلة: يعمل بصمت (بصرف النظر عن أصوات حركة السلسلة).

8. ميزات السلامة:

كلاهما: يجب أن يكون لها ميزات أمان أساسية مثل محددات الحمل/حماية الحمل الزائد والفرامل الميكانيكية. الرافعة الكهربائية غالبًا ما يتضمن ميزات إضافية مثل أزرار توقف الطوارئ, حماية المرحلة, وحماية الحمل الزائد الحراري للمحرك. تعتمد سلامة رفع السلسلة اعتمادًا كبيرًا على استخدام المشغل الصحيح ولا تتجاوز السعة.

1. التردد العالي, مهام الرفع المتكررة.

2. رفع الأحمال الأثقل بكفاءة.

3. التطبيقات التي تتطلب سرعات رفع/خفض أسرع.

4. المواقف التي يحتاج فيها تعب المشغل إلى الحد الأدنى.

5. التكامل في خطوط الإنتاج أو العمليات الآلية.

6. الرفع على ارتفاعات أكبر بشكل متكرر.

1. احتياجات رفع العرض في بعض الأحيان.

2. مهام تحديد موقع دقيقة (تثبيت الآلات, تنسيق).

3. التطبيقات التي لا تتوفر فيها الكهرباء, غير موثوق, أو خطرة.

4. مصاعد السعة المنخفضة حيث يمكن التحكم في جهود المشغل.

5. مشاريع واعية للميزانية.

6. المواقف التي تتطلب قابلية نقل عالية وإعداد سريع في مواقع مختلفة.

7. متاجر الصيانة, ورش عمل أصغر, العمل الميداني.

لا يوجد رافعة واحدة "أفضل". يعتمد الاختيار الصحيح تمامًا على احتياجاتك المحددة:

1. وزن الحمل & تكرار: كيف ثقيلة, عدد المرات?

2. ارتفاع ارتفاع & السرعة اللازمة: إلى أي مدى, كيف السرعة?

3. توافر الطاقة: الكهرباء الموثوقة في الموقع?

4. متطلبات الدقة: تحتاج إلى التحكم في غرامة?

5. ميزانية: التكلفة الأولية مقابل. تكاليف التشغيل طويلة الأجل?

6. قابلية النقل: تحتاج إلى تحريكها بشكل متكرر?

7. بيئة: مغبر, مبتل, الجو المتفجر? (يتطلب تصنيفات محددة).

من خلال وزن هذه العوامل بعناية ضد نقاط القوة والضعف من الرافعات الكهربائية والسلسلة, يمكنك تحديد أداة الرفع التي تزيد السلامة بثقة, كفاءة, والقيمة لتطبيقك المحدد. يتذكر, في بعض الأحيان يكون وجود واحد من كل منهما هو الحل الأمثل لمساحة عمل متعددة الاستخدامات!

A1: كلاهما يأتي في نطاقات مماثلة (على سبيل المثال, 0.5-20+ طن). لكن, الرافعات الكهربائية تتعامل مع الأحمال الثقيلة بكفاءة دون سلالة المشغل, بينما تعتمد رافعات السلسلة اليدوية على الجهد البشري (جعل الأحمال الثقيلة غير عملية للاستخدام المتكرر).

A2: مثالي ل:

1. رفع متكرر/متكرر.

2. الأحمال الثقيلة (1+ طن).

3. المهام التي تتطلب السرعة أو الحد الأدنى من التعب المشغل.

4. خطوط الإنتاج أو الإعدادات الآلية.

A3: اختر متى:

1. وضع الدقة أمر بالغ الأهمية (على سبيل المثال, محاذاة الآلات).

2. الكهرباء غير متوفرة أو خطرة.

3. قابلية النقل, تكلفة منخفضة, أو يتم إعطاء الأولوية للاستخدام العرضي.

4. أحمال أخف أو مصاعد نادرة.

نحن نقدر ملاحظاتك! يرجى إكمال النموذج أدناه حتى نتمكن من تخصيص خدماتنا حسب احتياجاتك المحددة.

رافعة كهربائية VEVOR مجهزة بمحرك نحاسي متين وتبديد حرارة متقدم ……

مع قدرة رفع تصل إلى 4 طن, هذا 4 الرافعة الكهربائية طن مثالية للمناولة……

لقد مرّ الرافعة الكهربائية للانفجار التي أنتجتها مجموعة Weihua الدولية .......

في تركيب معدات الطاقة, تصنيع الكابلات ونقل المواد الثقيلة, هو ……