Tired of the back-breaking, time-consuming chore of manually lifting heavy hay bales into your barn loft? Wrestling with hay hooks, pulleys, and sheer muscle power isn't just exhausting – it's a recipe for injury and inefficiency. The solution? An Agricultural Electric Hoist. This powerful tool is transforming hay handling, making it safer, faster, and significantly easier for modern farmers.

Online Chat

1. Brute Strength, Zero Strain: Forget pulling ropes. An electric hoist effortlessly lifts hundreds of kilograms (pounds) of hay with the simple push of a button. Your back, shoulders, and knees will thank you immediately. Dramatically reduce the risk of strains, sprains, and long-term musculoskeletal injuries.

2. Speed and Efficiency: What used to take multiple people significant time and effort can now be done solo in a fraction of the time. Load hay onto a trolley or hook below the hoist, engage the lift, and watch it smoothly ascend to the loft. Free up valuable labor for other essential farm tasks.

3. Precision Placement: Electric hoist offer controlled lifting and lowering. This allows you to position bales exactly where you need them in the loft, optimizing storage space and creating safer, more stable stacks. No more awkwardly shoving bales into place while balancing on a ladder.

4. Increased Capacity: Handle larger bales (round or square) or multiple smaller bales at once with ease. Electric hoists are designed for demanding agricultural loads.

5. Versatility: While hay lifting is a prime application, a robust electric hoist becomes invaluable for numerous other barn tasks:

Lifting heavy equipment for maintenance or repair.

Handling bags of feed or grain.

Moving bulky items like engines or machinery parts.

Assisting with livestock handling equipment installation.

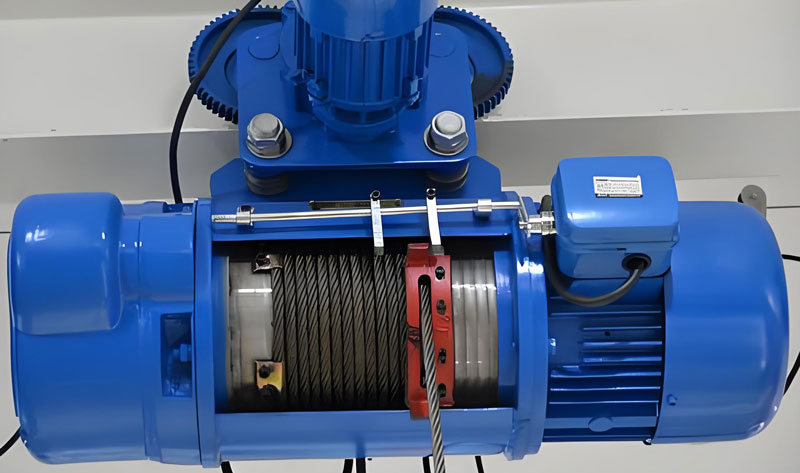

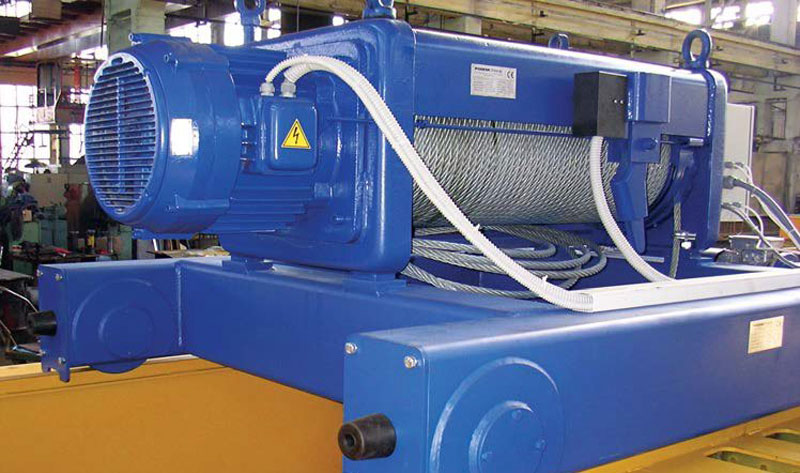

1. Robust Construction: It needs to withstand dusty, sometimes humid barn environments. Look for durable steel construction and reliable gearing.

2. Sufficient Lifting Capacity: Carefully calculate the weight you need to lift – consider the weight of wet hay, multiple bales, or a loaded pallet. Choose a hoist rated above your maximum expected load (e.g., 500kg/1100lbs hoist for 400kg/880lbs loads).

3. Adequate Lift Height: Measure the distance from your lower loading point to the highest point in your loft where you need to place hay. Ensure the hoist’s lift height (or chain length) exceeds this.

4. Duty Cycle: For frequent hay lifting, choose a hoist with a higher duty cycle (e.g., 30% or more) indicating it can handle sustained use without overheating.

5. Voltage & Power: Most farm hoists run on standard 110V/120V or 220V/240V single-phase power. Ensure your barn has suitable, safe electrical outlets where needed.

6. Control System: Remote controls (pendant or wireless) are essential for safe and convenient operation, allowing the operator to stand clear of the load. Look for clear up/down controls and an emergency stop.

7. Safety Features: Overload protection, thermal protection, mechanical brakes, and secure chain hooks are non-negotiable. Ensure the hoist meets relevant safety standards (like CE).

8. Trolley System (Crucial for Hay Lofts): A matching trolley that runs along a sturdy I-beam mounted in your loft allows you to lift the hay and move it horizontally to the perfect storage spot. Fixed hoists are less versatile for loft storage.

1. Structural Support is Paramount: The I-beam or supporting structure your hoist and trolley mount to MUST be engineered to handle the dynamic load (weight of hoist + trolley + max hay load + movement forces). Consult an engineer or qualified professional. Never mount to roof trusses or inadequately supported beams.

2. Secure Mounting: Follow the manufacturer’s instructions meticulously for mounting the beam, trolley, and hoist. Use appropriate, high-strength hardware.

3. Electrical Safety: Have wiring installed by a licensed electrician. Ensure proper grounding, circuit protection (correct breaker/fuse), and use of outdoor/agricultural-rated cable and outlets if exposed to elements or moisture. Protect wiring from physical damage and rodents.

1. Barn Structure: Is there a suitable, strong beam running the length of your loft? If not, installing one is a necessary (and worthwhile) investment.

2. Power Availability: Is there convenient power near the hoist’s mounting location? Running dedicated lines might be needed.

3. Hay Delivery Method: How will hay be presented to the hoist? (e.g., on a wagon, via a conveyor, manually stacked below?). Ensure clear access.

4. Dust: Hay dust is pervasive. Choose a hoist with good ingress protection (e.g., IP54 or higher) or be prepared for more frequent maintenance. Keep the hoist as clean as practical.

Investing in an agricultural electric hoist for your barn hay lifting is an investment in productivity, safety, and the well-being of everyone working on your farm. It eliminates one of the most physically demanding tasks, speeds up operations, and protects your most valuable asset – your health. The initial cost is quickly offset by reduced labor needs, increased efficiency, fewer injuries, and the sheer convenience of mechanizing this essential chore.

Ready to ditch the hay hooks and backaches? Research reputable agricultural equipment suppliers, get quotes for hoists and trolleys matching your specific barn setup and hay weight requirements, and consult professionals for installation. Your future self (and your back) will be grateful!

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.

Gantry crane with electric hoist is an efficient and flexible material handling equipmen……

As a leading brand in China’s lifting machinery industry, Weihua Group (WEIHUA) fo……

In the fast-paced, demanding environment of a modern warehouse, efficiency, safety, and ……

As the core product of small electric hoist, 1/2 ton electric chain hoist is suitable fo……