Operating in the offshore environment – whether it's oil & gas platforms, বায়ু খামার, শিপইয়ার্ড, or marine construction – presents unique and brutal challenges for equipment. Salt spray, constant humidity, chemical exposure, and extreme weather conspire to accelerate corrosion, the silent killer of machinery. When it comes to critical lifting equipment like offshore electric hoists, robust corrosion protection isn't just a feature; it's an absolute necessity for safety, নির্ভরযোগ্যতা, and longevity.

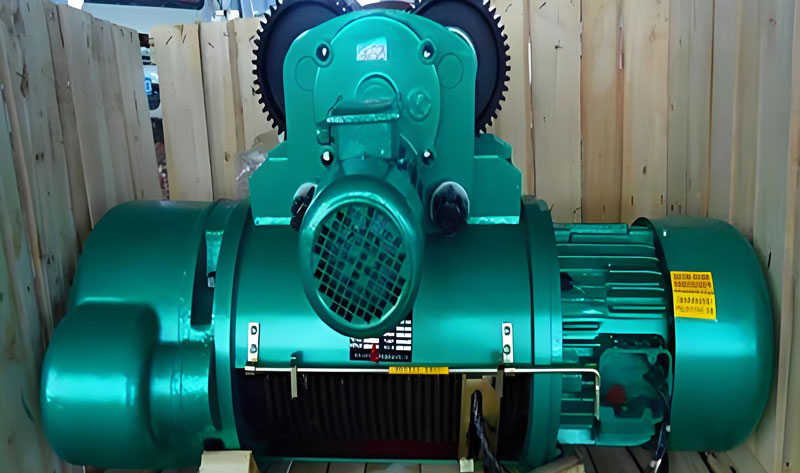

অনলাইন চ্যাটMarine electric hoists are specially designed for offshore operating environments and usually have excellent corrosion resistance. They are made of special materials that can effectively resist seawater erosion and salt spray corrosion, ensuring stable operation in harsh marine environments. These electric hoists are also usually waterproof and moisture-proof to adapt to the changing climate conditions at sea.

উপরন্তু, some ordinary electric hoists can also undergo special anti-corrosion treatment to enhance their corrosion resistance. যেমন, sandblasting the surface of the বৈদ্যুতিক উত্তোলন, applying anti-corrosion paint, or using corrosion-resistant materials such as stainless steel to make key components can improve its anti-corrosion performance to a certain extent. তবে, this approach may need to be customized based on specific use circumstances and needs.

| Parameter Category | স্পেসিফিকেশন |

| লোড ক্ষমতা | 1 - 50 টন |

| উচ্চতা উত্তোলন | পর্যন্ত 100 মি (মান) |

| উত্তোলনের গতি | 0.5 - 15 মি/আমার (পরিবর্তনশীল ফ্রিকোয়েন্সি ড্রাইভ) |

| পাওয়ার সাপ্লাই | 400V/440V AC, 50/60 Hz, 3-পর্যায় |

| ডিউটি ক্লাস | FEM 3 মি / আইএসএলটি6 |

| পরিবেষ্টিত তাপমাত্রা | -25°C থেকে +55°C |

| আইপি রেটিং | IP66/67 (মান), IP68/IP69K optional |

| Corrosion Certification | আইএসও 12944 C5-M (সামুদ্রিক) |

| Material Protection | |

| - হুকস & Load Chains | 316L Stainless Steel |

| - Structural Frame | Hot-dip galvanized steel + epoxy-polyurethane coating |

| - Gearbox/Motor Housing | Marine-grade aluminum (anodized) বা 316 SS |

| - Fasteners | A4/AISI 316 স্টেইনলেস স্টীল |

| Sealing System | Viton/EPDM gaskets + labyrinth seals |

| Motor Protection | Insulation Class H, IP66 |

| কন্ট্রোল সিস্টেম | IP65 pendant / Radio remote (IP67) |

| তারের দড়ি | 316 SS wire rope + corrosion-inhibiting grease |

| সার্টিফিকেশন | DNV-GL, ABS, Lloyds, সি.ই, OSHA |

| রক্ষণাবেক্ষণের ব্যবধান | 500–1,000 operating hours (offshore) |

Saltwater & Salt Spray: The primary aggressor. Salt is highly corrosive to most metals, accelerating rust and pitting, weakening structural components, and destroying electrical systems.

High Humidity: Constant moisture in the air prevents surfaces from drying, creating an ideal electrolyte for corrosion.

Temperature Fluctuations: Offshore environments experience wide temperature swings, causing condensation inside housings and accelerating chemical reactions.

Chemical Exposure: Potential contact with drilling fluids, hydraulic oils, cleaning chemicals, or exhaust fumes adds further corrosive elements.

Abrasive Particles: Wind-driven sand and salt crystals act like sandpaper, wearing away protective coatings.

Catastrophic Failure: Corrosion can weaken load-bearing hooks, চেইন, তারের দড়ি, and structural components, leading to dangerous drops.

Premature Component Failure: Motors, gearboxes, ব্রেক, and electrical controls are highly susceptible. Corrosion causes short circuits, bearing seizures, and control malfunctions.

Increased Downtime & Cost: Frequent repairs, part replacements, and unplanned maintenance halt operations and drive up costs significantly.

Safety Hazards: Compromised equipment integrity poses severe risks to personnel and surrounding assets.

1. Material Selection: The First Line of Defense

স্টেইনলেস স্টীল (SS): Essential for critical components exposed directly to the elements:

হুকস, Swivels, Load Chains: Typically high-grade stainless steel (যেমন, 316L or duplex grades) for maximum resistance to pitting and crevice corrosion.

Housings & Enclosures: Often constructed from marine-grade aluminum (with proper coatings) or stainless steel for motor and gearbox enclosures.

Fasteners: Stainless steel throughout.

Marine-Grade Aluminum: Used for housings and covers where weight is a consideration, always combined with protective coatings.

2. Advanced Surface Coatings & Treatments:

Multi-Layer Paint Systems: Not just paint, but sophisticated systems:

Zinc-Rich Primers: Provide sacrificial cathodic protection (like galvanizing).

Epoxy Intermediate Coats: Create a thick, impermeable barrier against moisture and chemicals.

Polyurethane Topcoats: Offer excellent UV resistance, color retention, and abrasion resistance. Colors are often specified for visibility and corrosion monitoring (যেমন, chalking).

Hot-Dip Galvanizing (HDG): Applied to structural steel components (like the hoist body frame or trolley frames) for a thick, durable zinc layer that provides sacrificial protection. Often overcoated with a compatible paint system for enhanced longevity and aesthetics.

Anodizing: Used on aluminum components to create a hard, corrosion-resistant oxide layer.

3. Sealed for the Environment:

IP66/67/68 & IP69K Ratings: Critical for electrical enclosures (মোটর, নিয়ন্ত্রণ বাক্স, pendant stations). These ratings ensure protection against powerful water jets, temporary immersion, and dust ingress.

High-Quality Seals & Gaskets: Vital around shafts, housing joints, cable entries, and control panels to prevent moisture and salt ingress. Materials like Viton or EPDM are common for their seawater and chemical resistance.

Pressurized Enclosures: For the most extreme environments, some hoists use slight positive pressure inside enclosures (with filtered air) to prevent external contaminants from entering.

4. Component-Specific Protection:

Corrosion-Resistant Motors: Motors specifically designed for offshore use feature encapsulated windings, stainless steel shafts, special bearings, and enhanced sealing.

Protected Gearboxes: Sealed against moisture ingress, using corrosion-resistant lubricants, and often featuring stainless steel or coated internals/casings.

Marine-Grade Wiring & Connectors: Wiring with tinned copper conductors resists corrosion, and connectors are sealed and often made of corrosion-resistant materials like brass with protective boots.

Stainless Steel Wire Rope or Chain: Essential for the lifting medium itself. Regular lubrication with a corrosion-inhibiting lubricant is also crucial maintenance.

Explicit Offshore/Marine Rating: Don’t settle for generic “weatherproof.” Look for hoists specifically designed and certified for offshore or marine applications.

Material Specifications: Verify the grades of stainless steel used (যেমন, 316L) and the type of coatings/paint systems applied (specify standards like ISO 12944 C5-M).

প্রবেশ সুরক্ষা (IP) Ratings: Ensure motor, গিয়ারবক্স, and control enclosures meet at least IP66. IP67/68 or IP69K offer superior protection.

সম্মতি: Check for relevant certifications (যেমন, DNV, ABS, Lloyds, GL) specific to offshore equipment.

Supplier Expertise: Partner with manufacturers and suppliers who have proven experience in the offshore sector and understand its harsh demands.

Even the best-protected hoist needs vigilant maintenance offshore:

Regular Washing: Rinse with fresh water (when safe and permitted) to remove salt deposits.

Inspections: Frequent visual checks for coating damage, rust spots, seal integrity, and corrosion on critical components.

Re-lubrication: Use only specified marine-grade, corrosion-inhibiting lubricants on chains, তারের দড়ি, গিয়ারস, and bearings.

Prompt Repair: Address any damage to coatings, seals, or components IMMEDIATELY to prevent corrosion from taking hold.

When choosing an offshore electric hoist with anti-corrosion features, it is recommended that you consider the following points:

An offshore electric hoist is a vital workhorse in one of the planet’s most punishing environments. Investing in a hoist engineered with comprehensive and robust corrosion protection isn’t an optional extra; it’s a fundamental requirement for operational safety, ব্যয়বহুল ডাউনটাইম হ্রাস করা, and achieving a worthwhile return on investment. When selecting your next offshore hoist, prioritize the specifications around materials, coatings, sealing, এবং সার্টিফিকেশন. মনে রাখবেন, in the battle against the sea, superior corrosion protection is your hoist’s strongest armor. বুদ্ধিমানের সাথে নির্বাচন করুন, maintain diligently, and operate safely.

আমরা আপনার মতামত মূল্য! দয়া করে নীচের ফর্মটি সম্পূর্ণ করুন যাতে আমরা আমাদের পরিষেবাগুলি আপনার নির্দিষ্ট প্রয়োজনের জন্য তৈরি করতে পারি.

ওয়েইহুয়া গ্রুপ দ্বারা উত্পাদিত বিস্ফোরণ প্রুফ বৈদ্যুতিক উত্তোলন আন্তর্জাতিক পাস করেছে ……

মূল সুবিধা এবং প্রযুক্তিগত হাইলাইট বুদ্ধিমান বেতার রিমোট কন্ট্রোল সিস্টেম এল…

ওয়েইহুয়া 1 রিমোট কন্ট্রোলের সাথে টন ইলেকট্রিক চেইন হোইস্ট বিশ্বস্ত প্রকৌশলকে একত্রিত করে, ……

সেতু বৈদ্যুতিক উত্তোলন পণ্য বৈশিষ্ট্য 1. মজবুত কাঠামো: উচ্চ-শক্তি দিয়ে নির্মিত……