In the world of lifting heavy loads, two stalwarts often stand side-by-side in workshops, almacenes, y sitios de construcción: the Electric Hoist and the Manual Chain Hoist (often simply called a Chain Hoist or Chain Block). While both serve the fundamental purpose of vertical lifting, their operation, capabilities, and ideal applications differ significantly. Choosing the wrong one can mean inefficiency, operator fatigue, or even inadequate power. Analicemos las diferencias clave.

Chat en línea

1. Fuente de energía & Operación:

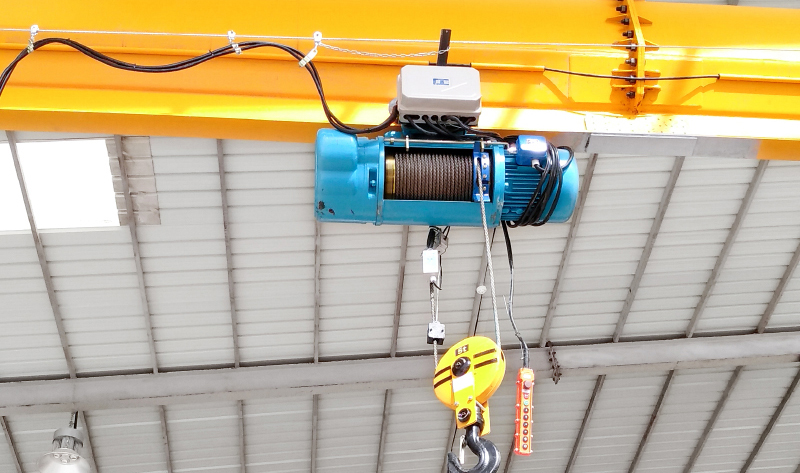

Polipasto eléctrico: Impulsado por un motor eléctrico.. El funcionamiento suele realizarse a través de un control colgante con botón pulsador. (arriba/abajo) or sometimes a radio remote. Requires a reliable electrical power source (single-phase or three-phase, dependiendo del modelo).

Polipasto de cadena: Powered purely by human effort. The operator pulls the hand chain in one direction to lift and the other direction to lower the load. No electricity needed.

2. Velocidad de elevación & Eficiencia:

Polipasto eléctrico: Significantly faster lifting and lowering speeds. Ideal for repetitive lifting tasks, high-volume operations, or moving loads over greater distances quickly. Boosts productivity dramatically.

Polipasto de cadena: Relatively slow lifting speed, entirely dependent on the operator’s strength and stamina. Best suited for occasional lifts, posicionamiento preciso, or lower frequency tasks. Can cause operator fatigue with heavy or frequent use.

3. Capacidad de levantamiento:

Polipasto eléctrico: Available in a vast range of capacities, from light-duty (P.EJ., 250 kg / 0.25 tonelada) to extremely heavy-duty models (50 tons+). Easily handles larger capacities efficiently.

Polipasto de cadena: Also available in a wide range of capacities (P.EJ., 500 kilogramos a 20 tons+ common). Sin embargo, the practical capacity is often limited by the operator’s ability to pull the chain effectively, especially near the hoist’s maximum rating. Very high-capacity models require immense effort.

4. Control & Precisión:

Polipasto eléctrico: Offers good control via variable-speed motors (on many models) for smooth starts/stops and positioning. Easier to operate consistently. Sin embargo, fine “inch” control might require specific features.

Polipasto de cadena: Provides excellent tactile feedback and very fine control for precise positioning (P.EJ., fitting machinery, aligning components). The operator directly feels the load.

5. Instalación & Requirements:

Polipasto eléctrico: Requires proper electrical wiring and often a robust supporting structure (haz, carretilla, portal) due to higher speeds and potential dynamic forces. Installation is generally more complex and requires qualified personnel.

Polipasto de cadena: Simpler installation. Primarily needs a suitable anchor point (gancho, lug) on a beam or structure. Highly portable – easily moved to different locations.

6. Cost Considerations:

Polipasto eléctrico: Higher initial purchase cost. Requires ongoing electrical costs. Potential for higher maintenance costs due to the motor, caja de cambios, and electrical components.

Polipasto de cadena: Lower initial purchase cost. No operating energy costs (beyond operator calories!). Generally lower maintenance costs (engranaje, aspectos, cadena).

7. Noise & Environment:

Polipasto eléctrico: Generates noise from the motor and gearbox during operation.

Polipasto de cadena: Operates silently (aside from chain movement sounds).

8. Características de seguridad:

Both: Should have essential safety features like load limiters/overload protection and mechanical brakes. Polipasto eléctrico often include additional features like emergency stop buttons, protección de fase, and thermal overload protection for the motor. Chain hoist safety relies heavily on correct operator use and not exceeding capacity.

1. High-frequency, repetitive lifting tasks.

2. Lifting heavier loads efficiently.

3. Applications requiring faster lifting/lowering speeds.

4. Situations where operator fatigue needs minimizing.

5. Integration into production lines or automated processes.

6. Lifting over greater heights frequently.

1. Occasional lifting needs.

2. Precise positioning tasks (machinery installation, alignment).

3. Applications where electricity is unavailable, unreliable, or hazardous.

4. Lower capacity lifts where operator effort is manageable.

5. Budget-conscious projects.

6. Situations requiring high portability and quick setup in different locations.

7. Maintenance shops, smaller workshops, field work.

There’s no single “best” hoist. The right choice hinges entirely on your specific needs:

1. Load Weight & Frecuencia: How heavy, how often?

2. Altura de elevación & Speed Needed: How far, how fast?

3. Power Availability: Reliable electricity on-site?

4. Precision Requirements: Need fine control?

5. Budget: Initial cost vs. long-term operating costs?

6. Portability: Need to move it around frequently?

7. Environment: Dusty, wet, explosive atmosphere? (Requires specific ratings).

By carefully weighing these factors against the strengths and weaknesses of electric and chain hoists, you can confidently select the lifting tool that maximizes safety, eficiencia, and value for your specific application. Recordar, sometimes having one of each is the perfect solution for a versatile workspace!

A1: Both come in similar capacity ranges (P.EJ., 0.5–20+ tons). Sin embargo, electric hoists handle heavy loads efficiently without operator strain, while manual chain hoists rely on human effort (making very heavy loads impractical for frequent use).

A2: Ideal for:

1. Frequent/repetitive lifting.

2. Heavy loads (1+ montones).

3. Tasks requiring speed or minimal operator fatigue.

4. Production lines or automated settings.

A3: Choose when:

1. Precision positioning is critical (P.EJ., machinery alignment).

2. Electricity is unavailable or hazardous.

3. Portability, bajo costo, or occasional use is prioritized.

4. Lighter loads or infrequent lifts.

Valoramos sus comentarios! Complete el formulario a continuación para que podamos adaptar nuestros servicios a sus necesidades específicas..

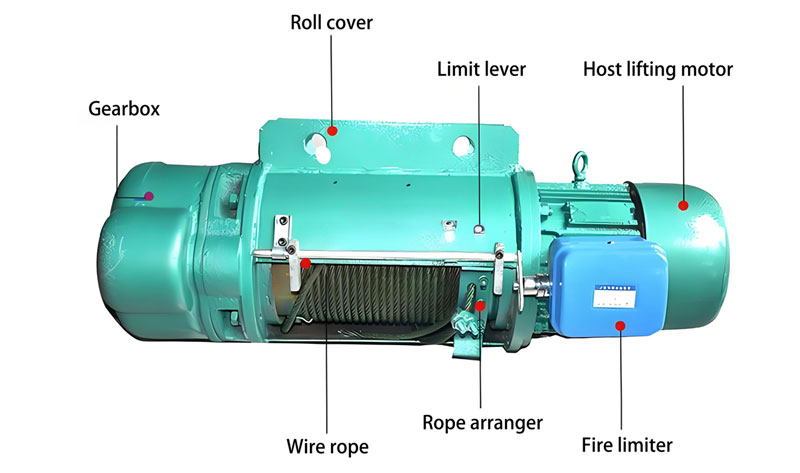

El polipasto de cable eléctrico de Weihua combina una estructura compacta con una gran capacidad de elevación. ……

Carcasa a prueba de explosión eléctrica, componentes eléctricos de precisión, y avanzado li ……

¿Por qué elegir un polipasto eléctrico Weihua para retirar el motor?? Polipastos de motor tradicionales (cereza……

Fortalezas del núcleo & Características clave del polipasto eléctrico 1. Robust Construction &a……