در دنیای بلند کردن بارهای سنگین, در کارگاهها معمولاً دو نیرومند در کنار هم قرار میگیرند, انبارها, و سایت های ساختمانی: بالابر برقی و بالابر زنجیر دستی (اغلب به سادگی بالابر زنجیری یا بلوک زنجیره ای نامیده می شود). در حالی که هر دو در خدمت هدف اساسی بلند کردن عمودی هستند, عملیات آنها, قابلیت ها, و کاربردهای ایده آل به طور قابل توجهی متفاوت است. انتخاب اشتباه می تواند به معنای ناکارآمدی باشد, خستگی اپراتور, یا حتی قدرت ناکافی. بیایید تفاوت های کلیدی را بشکنیم.

گپ آنلاین

1. منبع تغذیه & عملیات:

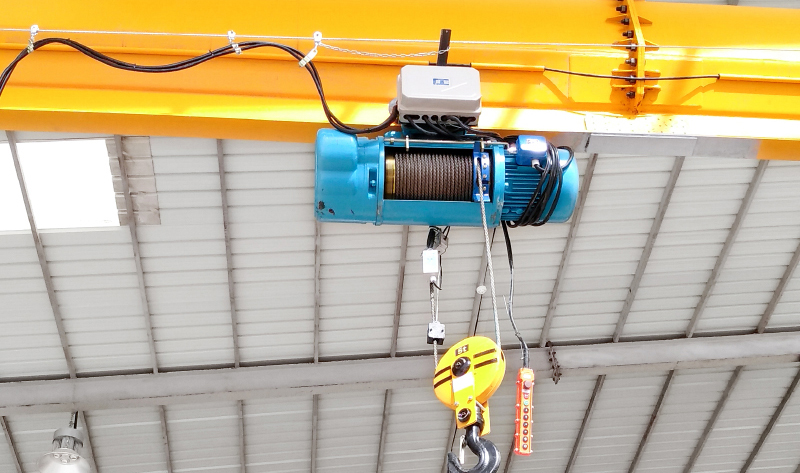

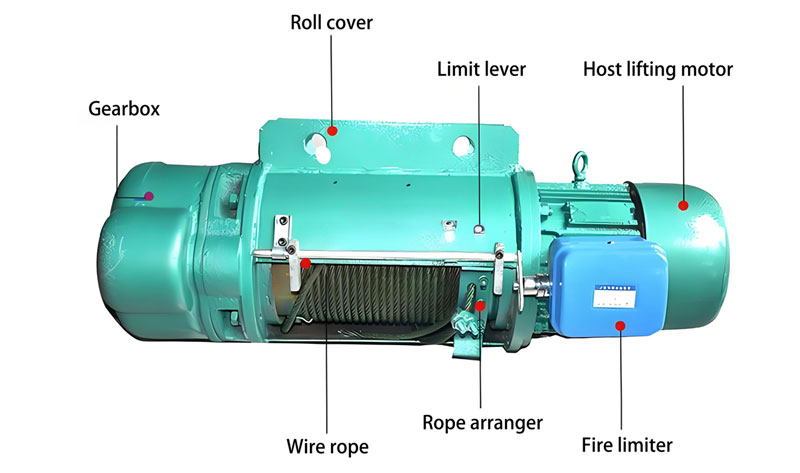

برقی برقی: با موتور الکتریکی تغذیه می شود. عملیات معمولاً از طریق یک کنترل آویز دکمه ای انجام می شود (بالا/پایین) یا گاهی اوقات یک ریموت رادیویی. به یک منبع برق قابل اعتماد نیاز دارد (تک فاز یا سه فاز, بسته به مدل).

بالابر زنجیر: صرفاً با تلاش انسانی. اپراتور زنجیر دستی را در یک جهت برای بلند کردن و جهت پایین آوردن بار می کشد. بدون نیاز به برق.

2. سرعت بلند کردن & کارایی:

برقی برقی: سرعت بالا بردن و پایین آوردن به طور قابل توجهی سریعتر. ایده آل برای کارهای تکراری بلند کردن, عملیات با حجم بالا, یا به سرعت بارها را در فواصل بزرگتر جابجا می کند. بهره وری را به طور چشمگیری افزایش می دهد.

بالابر زنجیر: سرعت بلند کردن نسبتاً آهسته, کاملاً به قدرت و استقامت اپراتور بستگی دارد. بهترین مناسب برای آسانسورهای گاه به گاه, موقعیت یابی دقیق, یا وظایف با فرکانس پایین تر. می تواند با استفاده زیاد یا مکرر باعث خستگی اپراتور شود.

3. ظرفیت بالابر:

برقی برقی: در طیف وسیعی از ظرفیت ها موجود است, از وظیفه سبک (به عنوان مثال, 250 کلوت / 0.25 تن) به مدل های بسیار سنگین (50 تن +). به راحتی ظرفیت های بزرگتر را به طور موثر اداره می کند.

بالابر زنجیر: همچنین در طیف گسترده ای از ظرفیت ها موجود است (به عنوان مثال, 500 کیلوگرم به 20 تن + رایج). با این حال, ظرفیت عملی اغلب توسط توانایی اپراتور برای کشیدن زنجیر به طور موثر محدود می شود, به خصوص نزدیک به حداکثر امتیاز بالابر. مدل های با ظرفیت بسیار بالا نیاز به تلاش زیادی دارند.

4. کنترل کردن & دقت:

برقی برقی: کنترل خوبی را از طریق موتورهای با سرعت متغیر ارائه می دهد (در بسیاری از مدل ها) برای شروع / توقف و موقعیت یابی صاف. کارکرد مداوم آسان تر. با این حال, کنترل "اینچی" خوب ممکن است به ویژگی های خاصی نیاز داشته باشد.

بالابر زنجیر: بازخورد لمسی عالی و کنترل بسیار خوب را برای موقعیت یابی دقیق فراهم می کند (به عنوان مثال, ماشین آلات اتصال, تراز کردن اجزا). اپراتور مستقیماً بار را احساس می کند.

5. نصب و راه اندازی & الزامات:

برقی برقی: نیاز به سیم کشی الکتریکی مناسب و اغلب ساختار حمایتی قوی دارد (پرتو, واگن برقی, لگد) به دلیل سرعت های بالاتر و نیروهای دینامیکی بالقوه. نصب به طور کلی پیچیده تر است و به پرسنل واجد شرایط نیاز دارد.

بالابر زنجیر: نصب ساده تر. در درجه اول به یک نقطه لنگر مناسب نیاز دارد (قلاب, پره) روی یک تیر یا سازه. بسیار قابل حمل - به راحتی به مکان های مختلف منتقل می شود.

6. ملاحظات هزینه:

برقی برقی: هزینه خرید اولیه بالاتر. مستلزم هزینه های مداوم برق است. پتانسیل هزینه های نگهداری بالاتر به دلیل موتور, گیربکس, و قطعات الکتریکی.

بالابر زنجیر: هزینه خرید اولیه کمتر. بدون هزینه انرژی عملیاتی (فراتر از کالری اپراتور!). به طور کلی هزینه های نگهداری کمتر است (چرخ دنده ها, بلبرینگ ها, زنجیره ای).

7. سر و صدا & محیط زیست:

برقی برقی: در حین کار از موتور و گیربکس صدا تولید می کند.

بالابر زنجیر: بی صدا عمل می کند (جدا از صداهای حرکت زنجیره ای).

8. ویژگی های ایمنی:

هر دو: باید دارای ویژگی های ایمنی ضروری مانند محدود کننده های بار/حفاظت اضافه بار و ترمزهای مکانیکی باشد. برقی برقی اغلب شامل ویژگی های اضافی مانند دکمه های توقف اضطراری است, حفاظت فاز, و حفاظت از اضافه بار حرارتی برای موتور. ایمنی بالابر زنجیری به شدت به استفاده صحیح اپراتور و عدم تجاوز از ظرفیت متکی است.

1. فرکانس بالا, کارهای تکراری بلند کردن.

2. بارهای سنگین تر را به طور موثر بلند کنید.

3. برنامههایی که به سرعت بالا بردن/کاهش سریعتر نیاز دارند.

4. شرایطی که خستگی اپراتور باید به حداقل برسد.

5. ادغام در خطوط تولید یا فرآیندهای خودکار.

6. بلند کردن مکرر از ارتفاعات بیشتر.

1. نیازهای گاه به گاه بلند کردن.

2. وظایف موقعیت یابی دقیق (نصب ماشین آلات, هم ترازی).

3. برنامه هایی که در آن برق در دسترس نیست, غیر قابل اعتماد, یا خطرناک.

4. بالابرهایی با ظرفیت کمتر که در آن تلاش اپراتور قابل مدیریت است.

5. پروژه های بودجه ای.

6. موقعیت هایی که به قابلیت حمل بالا و راه اندازی سریع در مکان های مختلف نیاز دارند.

7. مغازه های تعمیر و نگهداری, کارگاه های کوچکتر, کار میدانی.

هیچ "بهترین" بالابر واحدی وجود ندارد. انتخاب صحیح کاملاً به نیازهای خاص شما بستگی دارد:

1. وزن بار & فرکانس: چقدر سنگینه, هر چند وقت یکبار?

2. ارتفاع بالابر & سرعت مورد نیاز: تا کجا, چقدر سریع?

3. در دسترس بودن نیرو: برق قابل اطمینان در محل?

4. الزامات دقت: نیاز به کنترل دقیق?

5. بودجه: هزینه اولیه در مقابل. هزینه های عملیاتی بلند مدت?

6. قابل حمل بودن: نیاز به جابجایی مکرر آن?

7. محیط زیست: گرد و غبار, مرطوب, جو انفجاری? (به رتبه بندی های خاصی نیاز دارد).

با سنجیدن دقیق این عوامل با نقاط قوت و ضعف بالابرهای برقی و زنجیری, می توانید با اطمینان ابزار بالابری را انتخاب کنید که ایمنی را به حداکثر می رساند, بهره وری, و ارزش برای برنامه خاص شما. به یاد داشته باشید, گاهی اوقات داشتن یکی از هر یک راه حل عالی برای یک فضای کاری همه کاره است!

A1: هر دو در محدوده ظرفیت مشابه هستند (به عنوان مثال, 0.5-20+ تن). با این حال, بالابرهای الکتریکی بارهای سنگین را به طور موثر و بدون فشار اپراتور تحمل می کنند, در حالی که بالابرهای زنجیری دستی به تلاش انسان متکی هستند (بارهای بسیار سنگین را برای استفاده مکرر غیر عملی می کند).

A2: ایده آل برای:

1. بلند کردن مکرر / مکرر.

2. بارهای سنگین (1+ تن).

3. کارهایی که نیاز به سرعت یا حداقل خستگی اپراتور دارند.

4. خطوط تولید یا تنظیمات خودکار.

A3: انتخاب کنید چه زمانی:

1. موقعیت یابی دقیق بسیار مهم است (به عنوان مثال, تراز ماشین آلات).

2. برق در دسترس نیست یا خطرناک است.

3. قابل حمل بودن, کم هزینه, یا استفاده گاه به گاه در اولویت است.

4. بارهای سبک تر یا بالابرهای نادر.

ما برای بازخورد شما ارزش قائل هستیم! لطفاً فرم زیر را تکمیل کنید تا بتوانیم خدمات خود را متناسب با نیازهای خاص شما تنظیم کنیم.

جرثقیل دروازه ای با بالابر برقی یک تجهیزات کارآمد و انعطاف پذیر برای جابجایی مواد است. …

بالابر برقی Weihua برای کارگاه گاراژ خانگی یک دستگاه فشرده است, کارآمد, و قدرتمند……

Harbour Freight Electric Hoist یک تجهیزات بالابر سنگین است که مخصوص بندرگاه طراحی شده است ...

20 ft پارامترهای بالابر کابل برق طبقه بندی نام پارامتر جزئیات پی ……