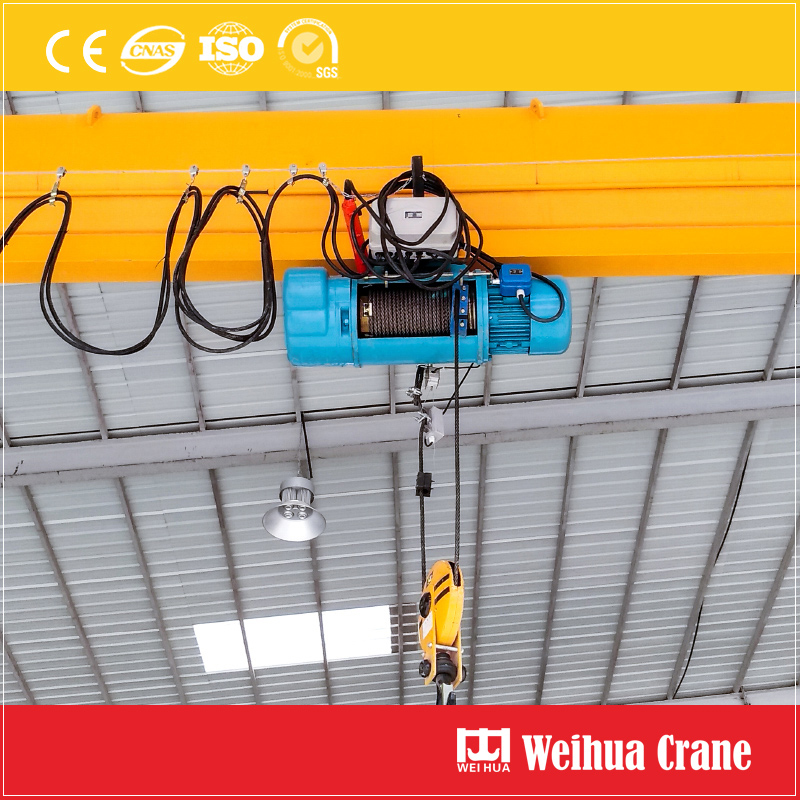

The magic of theater lies in seamless transitions, breathtaking reveals, and dynamic environments. Flying carpets soar, intricate sets transform in seconds, and dazzling lighting grids descend with precision. Behind this illusion of effortless motion lies a critical piece of technology: the electric hoist for stage rigging and theater use. More than just a motor, it's the workhorse powering the spectacle, demanding unwavering reliability and safety.

ऑनलाइन चैटएक electric hoist for stage rigging and theater use is a motorized lifting device specifically designed for the unique demands of live performance environments. Unlike industrial hoists, these units prioritize:

1. Silent Operation: Imagine a climactic soliloquy interrupted by a grinding motor! Stage hoists feature specialized gearboxes and motors engineered for near-silent running.

2. Precise Control: Smooth starts, stops, and variable speed control are non-negotiable. Scenery must move fluidly at the exact pace the director envisions. Modern hoists often integrate with sophisticated control consoles for intricate cueing.

3. Ultimate Safety: Safety is paramount above performers, crew, and audiences. Theater hoists incorporate multiple redundant safety systems:

यांत्रिक भार ब्रेक: Automatically engage if power fails.

अधिभार संरक्षण: Prevents lifting beyond safe capacity.

सीमा स्विच: Prevents over-travel at the top and bottom.

Two-Brake Systems: Often standard.

Rigorous Compliance: Adherence to strict standards like ANSI E1.6 (Entertainment Technology – Powered Hoist Systems), BS 7906, and EN 17206 is essential.

4. सहनशीलता & विश्वसनीयता: They must withstand constant use, frequent load changes, and the dusty backstage environment. High-quality components and robust construction are critical.

5. संक्षिप्त परिरूप: Space is always at a premium backstage. Hoists need a small footprint relative to their lifting capacity.

The electric hoist for stage rigging and theater use is incredibly versatile:

Flying Scenery: Lifting and lowering backdrops, legs, borders, platforms, and complex scenic pieces – the core function.

Lighting Rigging: Positioning and focusing heavy lighting battens (trusses) and individual luminaires.

Audio Rigging: Flying speaker clusters and delay towers.

Curtain Control: Operating heavy main drapes, travelers, and cycloramas.

Special Effects: Flying performers (with specialized rigs and trained operators), moving props, or creating dynamic stage elements.

Orchestra Pit Lifts: Raising and lowering entire pit sections.

While manual counterweight systems still exist (and have their place), electric hoist systems for stage rigging and theater use offer compelling advantages:

Increased Load Capacity & ऊंचाई: Capable of handling heavier and larger scenic elements to greater heights.

Faster Set Changes: Programmable cues allow multiple hoists to operate simultaneously and precisely, enabling incredibly swift and complex scene shifts.

Reduced Physical Strain: Eliminates the need for large crews pulling on counterweight ropes, minimizing injury risk and fatigue.

Enhanced Flexibility & नियंत्रण: Speed variations, precise positioning, and integration with automation systems allow for choreographed movement impossible manually.

Space Efficiency: Hoists mount directly to the grid or structure, often freeing up valuable wing space compared to counterweight arbors.

रिमोट ऑपरेशन: Operators can control the system safely from the stage deck or a dedicated control booth.

Selecting the ideal electric hoist for stage rigging and theater use requires careful consideration:

1. उठाने की क्षमता (SWL – Safe Working Load): Determine the maximum weight the hoist needs to lift, including the scenery, rigging hardware, and bridles. Always include a safety factor.

2. लिफ्ट की ऊंचाई & रफ़्तार: How far does it need to travel? How fast does it need to move the load? (Speed often varies with load).

3. साइकिल शुल्क: How frequently will it be used? Continuous duty hoists are needed for high-use applications.

4. नियंत्रण प्रणाली: Simple pendant control? Integrated into a larger DMX/Art-Net or proprietary automation console? Compatibility is key.

5. Noise Level: Measured in dB(ए). Crucial for intimate theater spaces.

6. Safety Certifications: Verify compliance with relevant standards (ANSI E1.6, EN 17206, BS 7906).

7. Brand Reputation & सहायता: Choose reputable manufacturers known for quality, विश्वसनीयता, and excellent technical support/service. (उदा।, CM Lodestar, Verlinde, Stagemaker, ZFX – though brand names shouldn’t dominate SEO text).

8. इंस्टालेशन & Maintenance: Factor in professional installation by certified riggers and a robust maintenance schedule. Hoists are safety-critical devices.

Working with electric hoists for stage rigging and theater use demands the highest safety standards:

Professional Installation & Inspection: Always use certified theatrical riggers for installation and regular inspections.

Qualified Operators: Only trained personnel should operate the system.

Regular Maintenance: Strict adherence to the manufacturer’s maintenance schedule is mandatory.

Load Testing: Performed after installation, significant modifications, or at regular intervals as dictated by regulations.

Never Exceed SWL: This is an absolute rule.

Use Appropriate Rigging Hardware: Shackles, trusses, and cables must all be rated appropriately and inspected.

हम आपकी प्रतिक्रिया को महत्व देते हैं! कृपया नीचे दिए गए फ़ॉर्म को पूरा करें ताकि हम आपकी सेवाओं को आपकी विशिष्ट आवश्यकताओं के लिए दर्जी कर सकें.

उत्पाद अवलोकन FEM स्टैंडर्ड वायर रोप इलेक्ट्रिक होइस्ट एक उच्च प्रदर्शन वाला लिफ्टिन है......

15 टन तार रस्सी इलेक्ट्रिक लहरा प्रमुख विशेषताएं & फ़ायदे 1. असाधारण लिफ्टिंग सीए ……

VEVOR electric hoist equipped with a durable copper motor and advanced heat dissipation ……

इलेक्ट्रिक विंच होइस्ट क्या है? विद्युत चरखी लहरा एक विद्युत चालित कर्षण है......