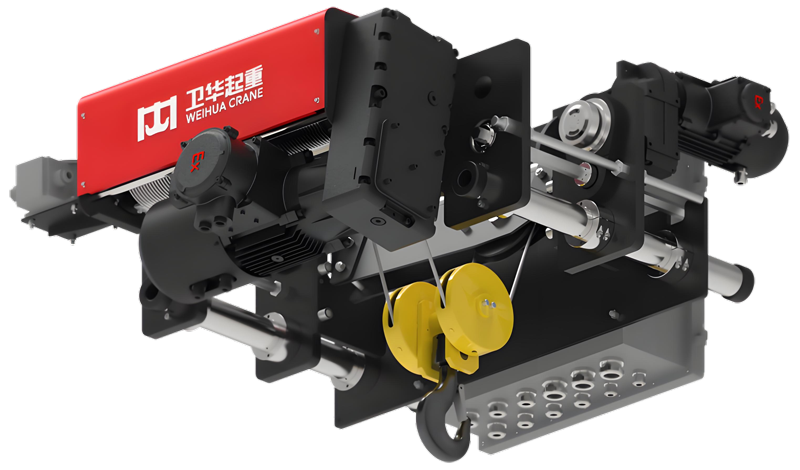

विस्फोट रोधी इलेक्ट्रिक होइस्ट एक विस्फोट रोधी उठाने वाला उपकरण है जिसे वेहुआ द्वारा नवीनतम विस्फोट प्रूफ मानकों के अनुसार डिजाइन और निर्मित किया गया है. विस्फोट रोधी इलेक्ट्रिक होइस्ट के खुले विस्फोट रोधी हिस्से विशेष गैर-स्पार्किंग सामग्री से बने होते हैं, और विस्फोट रोधी प्रदर्शन सुरक्षित और विश्वसनीय है. विस्फोट रोधी विद्युत लहरा का उपयोग उच्च जोखिम में किया जा सकता है, ज्वलनशील एवं विस्फोटक स्थान

वीहुआ ग्रुप द्वारा निर्मित विस्फोट प्रूफ इलेक्ट्रिक होइस्ट ने अंतरराष्ट्रीय ATEX/IECEx विस्फोट प्रूफ प्रमाणीकरण पारित कर दिया है और इसे विशेष रूप से जोन 1/जोन के लिए डिज़ाइन किया गया है। 2 खतरनाक क्षेत्र, शून्य चिंगारी और कम सतह तापमान के साथ पूर्ण सुरक्षित संचालन गारंटी प्रदान करना. विस्फोट रोधी इलेक्ट्रिक होइस्ट का उपयोग अक्सर खतरनाक क्षेत्रों में किया जाता है जहां ज्वलनशील और विस्फोटक गैसें/धूल मौजूद होती हैं, जैसे पेट्रोकेमिकल उद्योग, प्राकृतिक गैस खनन, खनन कार्य, और फार्मास्युटिकल कार्यशालाएँ. चूँकि साधारण विद्युत तरंगों से निकली चिंगारी या उच्च तापमान भयावह दुर्घटनाओं का कारण बन सकते हैं, विस्फोट रोधी विद्युत लहरा की आवश्यकता है.

विस्फोट रोधी विद्युत लहरा

संभावित सुरक्षा खतरों को खत्म करने के लिए सैन्य-ग्रेड विस्फोट रोधी डिज़ाइन

बुद्धिमान नियंत्रण, सटीक और कुशल

अत्यधिक पर्यावरणीय अनुकूलनशीलता और स्थायित्व

विस्फोट रोधी विद्युत लहरा

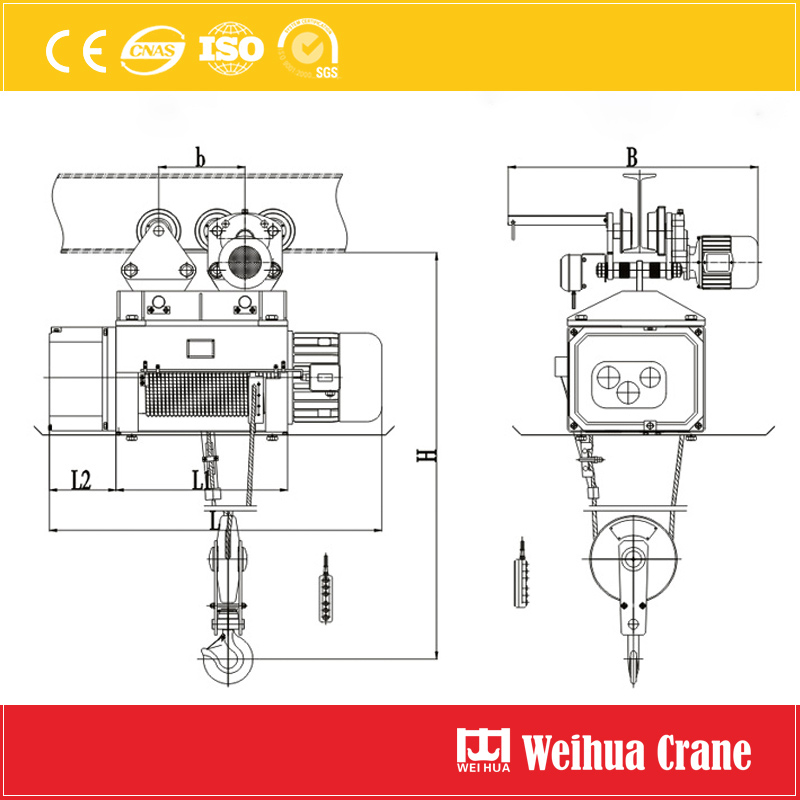

| परियोजना | पैरामीटर रेंज |

| क्षमता | 0.5 टन, 1 टन, 2 टन, 3 टन, 5 टन, 10 टन, 30 टन, 50 टन, 100 टन (अनुकूलन समर्थित है) |

| उठाने की ऊँचाई | 3मी~30 मी (मानक), 100 मीटर तक अनुकूलित किया जा सकता है |

| उठाने की गति | एकल गति: 8मी/मेरा; दोगुनी गति: 8/0.8मी/मेरा; परिवर्तनीय आवृत्ति गति विनियमन: 0.1-10मी/मेरा |

| यात्रा की गति | 10-20मी/मेरा (ज़मीन पर हाथ से धक्का) / 20-30मी/मेरा (विद्युत संचालन) |

| कर्तव्य वर्ग | फेम 1 पूर्वाह्न ~ 2 मिनट / आईएसओ एम3 ~ एम5 |

| बिजली की आपूर्ति | 380V/50Hz तीन-चरण एसी (वैकल्पिक 220V/60Hz) |

विस्फोट रोधी प्रमाणीकरण

विस्फोट रोधी घटक विन्यास

सुरक्षा अनावश्यक डिज़ाइन

विस्फोट रोधी विद्युत लहरा

| भाग | तकनीकी निर्देश |

| तार रस्सी | एंटी-रोटेशन प्रकार 6×36WS+IWR, गैल्वेनाइज्ड/स्टेनलेस स्टील (संक्षारण रोधी विकल्प) |

| अंकुश | मिश्र धातु इस्पात से जाली, सुरक्षा जीभ + रोटेशन लॉक, लोड का परीक्षण किया गया 1.25 टाइम्स |

| ट्रैक अनुकूलन | मैं दमक (160~400 मिमी पेट की चौड़ाई)/केबीके लाइट ट्रैक/अनुकूलित स्टील |

| शैल कोटिंग | एपॉक्सी राल पाउडर कोटिंग (मोटाई ≥120μm), नमक स्प्रे प्रतिरोध 2000h |

| उद्योग | आवेदन के मामले | विस्फोट-रोधी आवश्यकताएँ |

| पेट्रोकेमिकल उद्योग | रिफाइनरी रिएक्टर उत्थापन और टैंक क्षेत्र उपकरण रखरखाव | क्लास IIA/IIB/IIC गैस विस्फोटों से सुरक्षा |

| भूमिगत कोयला खदान | शियरर घटकों की स्थापना और वेंटिलेशन उपकरण में सुधार | मीथेन गैस + धूल डबल विस्फोट रोधी |

| अनाज प्रसंस्करण | आटा साइलो संप्रेषण प्रणाली, स्टार्च उत्पादन लाइन उत्थापन | धूल विस्फोट संरक्षण (ST3 स्तर) |

| एयरोस्पेस | रॉकेट ईंधन भंडारण टैंक हैंडलिंग, हैंगर रखरखाव उपकरण उठाना | एंटी-हाइड्रोजन/केरोसिन एयरोसोल विस्फोट |

| नई ऊर्जा विनिर्माण | लिथियम बैटरी इलेक्ट्रोड सामग्री हैंडलिंग, हाइड्रोजन ऊर्जा बैटरी पैक असेंबली | धातु विरोधी धूल + हाइड्रोजन मिश्रित विस्फोट जोखिम |

विस्फोट रोधी विद्युत लहरा

विस्फोट रोधी विद्युत लहरा निर्माण प्रक्रिया

विस्फोट रोधी विद्युत लहरा निर्माता

अभी अपना विशेष प्लान प्राप्त करें

📞व्हाट्सएप: +86 13613816589

📧आधिकारिक ईमेल: Aiden@craneweihua.com

🌐ऑनलाइन परामर्श: विस्फोट रोधी इलेक्ट्रिक होइस्ट से संपर्क करने के लिए क्लिक करें

मुखपृष्ठ: HTTPS के://www.weihualargecrane.com

हम आपकी प्रतिक्रिया को महत्व देते हैं! कृपया नीचे दिए गए फ़ॉर्म को पूरा करें ताकि हम आपकी सेवाओं को आपकी विशिष्ट आवश्यकताओं के लिए दर्जी कर सकें.

रिमोट कंट्रोल तकनीकी मापदंडों के साथ इलेक्ट्रिक होइस्ट पैरामीटर सामान्य विशिष्टता……

निर्माण के लिए वेइहुआ इलेक्ट्रिक होइस्ट की मुख्य विशेषताएं 1. उच्च उठाने की क्षमता & वे......

वैरिएबल स्पीड इलेक्ट्रिक होइस्ट कोर वैरिएबल फ्रीक्वेंसी ड्राइव मॉड्यूल इनफिनियन आईजीबी का उपयोग करता है......

The 3 टन इलेक्ट्रिक चेन होइस्ट वेहुआ जी द्वारा विकसित एक मध्यम आकार का उठाने वाला उपकरण है......