Electric hoists have become an essential component in modern warehousing and logistics operations. As industries evolve to meet higher demands for efficiency and safety, the adoption of electric hoists in material handling has significantly increased. These powerful lifting devices streamline processes, reduce manual labor, and improve workplace safety — all critical factors in warehousing and logistics success.

Obrolan onlineIn busy warehouses and logistics hubs, fast and secure movement of goods is crucial. Electric hoists play a key role by providing reliable lifting solutions for heavy or bulky items. Compared to manual or hydraulic systems, electric hoists offer:

1. Faster load handling: Electric motors increase the speed of lifting and lowering operations.

2. Greater lifting capacity: Models range from light-duty (0.5 ton) to heavy-duty (30 tons or more).

3. Improved accuracy: Many kerekan listrik allow for precise vertical control, reducing product damage.

4. Enhanced safety: Dilengkapi dengan perlindungan kelebihan beban, emergency stop features, and limit switches.

Electric hoists are used in a wide variety of settings, termasuk:

1. Pallet Handling: Lifting and stacking loaded pallets quickly and safely.

2. Inventory Management: Moving goods to and from high shelving or mezzanine levels.

3. Truck Loading/Unloading: Assisting in the transfer of materials between transport vehicles and storage zones.

4. Jalur Perakitan: In distribution centers with assembly or repackaging tasks.

5. Cold Storage Facilities: Hoists designed for low-temperature environments aid in the movement of refrigerated goods.

Warehouses typically use the following electric hoists:

Electric Chain Hoists: Ideal for lighter loads and high-frequency lifting.

Electric Wire Rope Hoists: Suitable for heavier loads and demanding conditions.

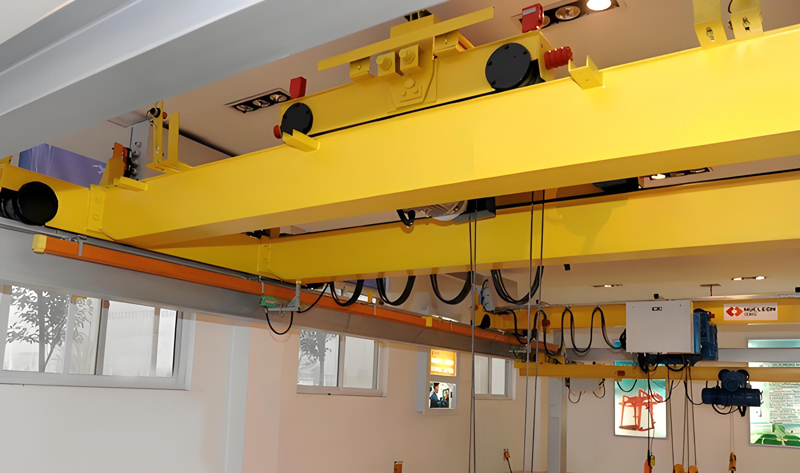

Overhead Electric Hoist: For moving goods across large spans in large warehouses.

1. Time-Saving: Reduce load handling time and labor costs.

2. Consistent Performance: Electric hoists deliver steady and repeatable lifting cycles.

3. Adaptability: Compatible with different crane systems or standalone structures.

4. Energy Efficiency: Modern models are energy-conscious with regenerative braking systems.

5. Pemeliharaan rendah: Designed for longevity with minimal servicing required.

When selecting an electric hoist for warehousing or logistics purposes, consider:

1. Load capacity requirements

2. Lift height and speed

3. Frekuensi penggunaan

4. Environmental conditions (MISALNYA., debu, temperature)

5. Safety standards and certifications (such as CE, Iso, or ASME)

Electric hoists are transforming how goods are handled in warehousing and logistics environments. Their efficiency, safety features, and versatility make them an indispensable tool for operations aiming to increase productivity and reduce manual labor. Whether managing pallets or moving heavy machinery, electric hoists provide a reliable solution that supports the growing demands of modern supply chains.

Kami menghargai tanggapan Anda! Harap lengkapi formulir di bawah ini sehingga kami dapat menyesuaikan layanan kami dengan kebutuhan spesifik Anda.

Ikhtisar Produk Kerekan Listrik Tali Kawat Standar FEM adalah alat angkat berperforma tinggi……

WeiHua Low Headroom Electric Chain Hoist dirancang khusus untuk aplikasi di mana……

Gantry crane dengan kerekan listrik adalah peralatan penanganan material yang efisien dan fleksibel……

Keunggulan inti dan sorotan teknis Sistem kendali jarak jauh nirkabel yang cerdas aku……