Saudi Steel Mill Case: How a Custom 32-Ton Overhead Crane Transformed Steel Coil Handling. Resolving aging equipment downtime, safety risks & SASO non-compliance, it boosted efficiency by 60%, ensured full compliance, and achieved 24-month ROI.

Chat onlineAs Saudi Arabia advances its industrial diversification under Vision 2030, the local steel sector is experiencing unprecedented growth—driving demand for robust, efficiente, and reliable material handling solutions. A prominent steel mill in the Eastern Province, a hub of the country’s manufacturing activity, recently faced a pivotal hurdle in its production chain: its decades-old overhead crane, once a workhorse for steel coil transportation, had become a liability. Struggling to cope with increased production volumes and the rigors of daily heavy-load operations, the mill turned to a customized 32-ton double girder overhead bridge crane to revitalize its coil handling process and align with its expansion goals.

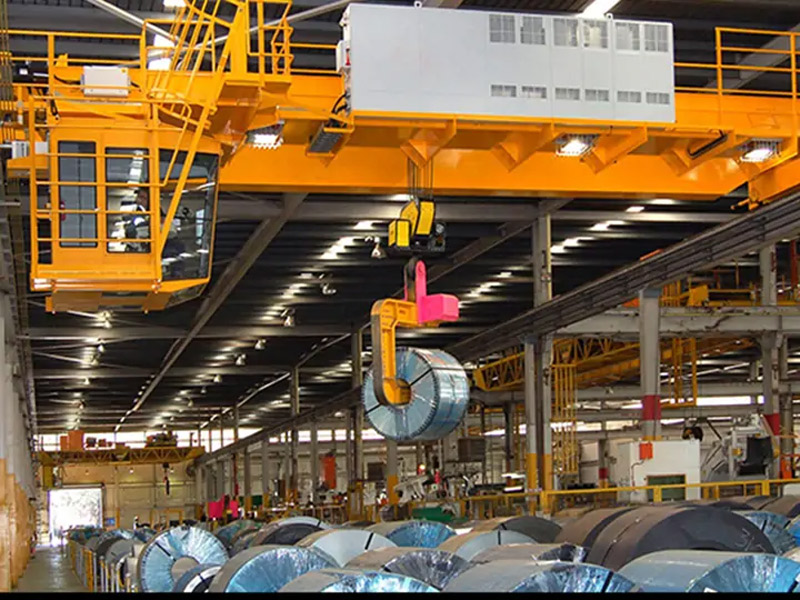

For over 15 years, the mill relied on a single-girder overhead crane to move steel coils—ranging from 18 A 32 tons—across its 12,000-square-meter production facility. As the mill scaled up to meet the growing demand for construction-grade steel in Saudi Arabia’s infrastructure boom, the limitations of the old crane became increasingly apparent, creating a cascade of operational challenges:

Faced with these challenges, the mill’s engineering and operations teams collaborated to define clear criteria for a replacement crane: it needed to handle 32-ton coils with ease, withstand desert environmental conditions, comply with the latest Saudi regulations, and deliver a measurable boost in operational efficiency.

After a rigorous selection process focused on manufacturers with expertise in desert industrial solutions, the mill partnered with a specialist to develop a fully customized 32-ton double girder overhead bridge crane. Every aspect of the crane was engineered to address the mill’s specific pain points and adapt to Saudi Arabia’s unique operational environment. Key custom features included:

To combat the harsh desert conditions, the crane’s structural frame was fabricated using high-strength weathering steel, treated with a dual-layer anti-corrosion coating (epoxy primer + polyurethane topcoat) to resist steel dust and humidity. All electrical enclosures were upgraded to IP65 rating—providing superior dust and water protection compared to the old crane’s IP44 rating. Inoltre, a dedicated forced-air cooling system was installed for the crane’s motor and control panel, ensuring stable performance even at peak temperatures of 52°C.

The crane was fully certified to meet SASO 2710 Rev.2 and SABER requirements. It featured a real-time load monitoring system with digital displays in both Arabic and English, audible overload alarms, and an emergency stop network (with 6 strategically placed buttons across the facility). A black box data recorder was also integrated to track crane operations—another regulatory mandate—allowing the mill to maintain detailed safety logs for inspections. The crane’s control system was designed with intuitive, localized interfaces, reducing the learning curve for local operators.

Recognizing the delicate nature of steel coils (which can be damaged by improper gripping), the crane was equipped with a custom-engineered adjustable C-hook attachment. The hook’s inner surface was lined with high-density rubber to prevent scratches on the coil surface, while its width could be adjusted between 600mm and 1200mm to accommodate the mill’s varying coil sizes. A state-of-the-art anti-sway system was also integrated, reducing load swing by 85% during movement and enabling precise positioning of coils—critical for loading onto shipping containers and storage racks.

The crane’s hoisting system was upgraded to a variable-frequency drive (VFD) motore, increasing hoisting speed to 9 m/mio (double the old crane’s speed) while maintaining smooth, controlled movement. The trolley and bridge travel speeds were also optimized, cutting the time to transfer a 32-ton coil from the rolling mill to storage to just 6 minutes. A regenerative braking system was added to reduce energy consumption by 15%, aligning with the mill’s sustainability goals.

Since the installation of the new 32-ton overhead crane in Q2 2025, the steel mill has seen a profound positive impact on its operations, with measurable improvements across key performance metrics:

“Investing in this customized 32-ton overhead crane was one of the best decisions we’ve made for our production operations,” said the mill’s General Manager. “It’s not just a piece of equipment—it’s a solution that understands our environment, our safety needs, and our growth ambitions. The efficiency gains and safety improvements have transformed our workflow, allowing us to keep up with Saudi Arabia’s growing demand for high-quality steel.”

This case study underscores a critical truth for Saudi Arabia’s steel industry: in a period of rapid growth and evolving regulations, generic equipment is no longer sufficient. A customized overhead crane—engineered to withstand local environmental conditions, comply with national standards, and adapt to specific handling needs—delivers far greater value than one-size-fits-all solutions.

For steel mills looking to upgrade their material handling equipment, the focus should be on partnering with providers who understand the unique challenges of the Saudi industrial landscape. By prioritizing customization, sicurezza, and compliance, mills can not only resolve immediate operational bottlenecks but also lay the groundwork for sustainable growth in line with Vision 2030’s industrial goals.

Apprezziamo il tuo feedback! Completa il modulo sottostante in modo da poter personalizzare i nostri servizi alle tue esigenze specifiche.

Caratteristiche principali del paranco elettrico per carichi pesanti ✅ Elevata capacità di sollevamento:Elettrici per carichi pesanti Weihua……

Perché scegliere un paranco elettrico Weihua per la rimozione del motore? Paranchi tradizionali (ciliegia……

Nei magazzini, fabbriche, e linee di assemblaggio in tutto il mondo, il tempo è la valuta definitiva. T……

Custodia antideflagrante per paranco elettrico, componenti elettrici di precisione, e li avanzato……