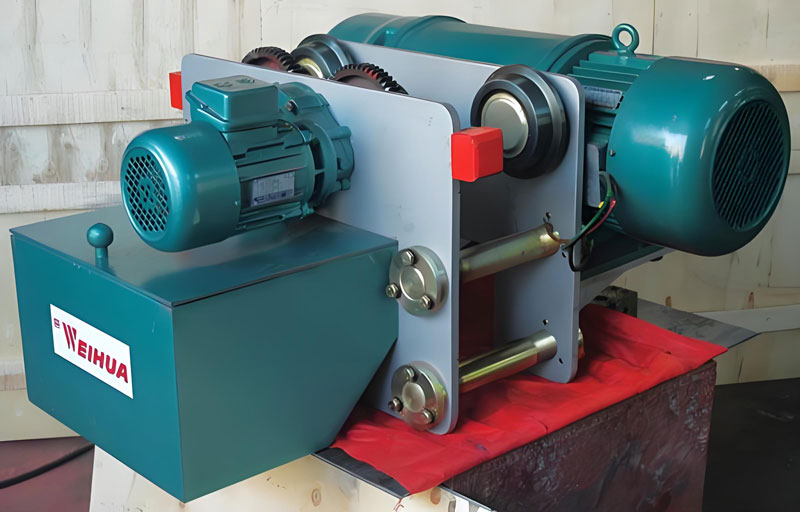

The electric cable hoist developed by Weihua Group has the world's leading industry customized services. The electric cable hoist adopts a heavy-duty and durable structure design and is combined with multiple safety guarantee mechanisms. It is widely used in hoisting and transfer projects of heavy materials.

Nell'installazione di apparecchiature elettriche, produzione di cavi e trasferimento di materiali pesanti, the hoisting of large cable drums, transformers or steel coils is a core part of high-risk, high-precision operations. Traditional lifting equipment can easily cause load swings, inaccurate positioning and even equipment damage. The electric cable hoist developed by Gruppo Weihua specifically for this scenario combines precision control technology, enhanced structural design and industry-specific functions to redefine the safety and efficiency standards for heavy-duty coil handling.

| Progetto | Parameter range |

| Carico nominale | 10T, 16T, 20T, 32T, 50T, 100T |

| Altezza di sollevamento | 6m ~ 30m (customized up to 50m+) |

| Velocità di lavoro | Main lifting: 0.5~8m/min (variable frequency)

Car operation: 2~20m/min |

| Livello lavorativo | FEM-M8 / ISO M8 |

| Livello di protezione | IP55 (indoor), IP65 (outdoor) |

| Metodo di controllo | Joystick/remote control + Autobus CAN |

| Positioning accuracy | ±1mm (optional i-Swing system) |

| Alimentazione elettrica | 380V/50Hz or 480V/60Hz (può essere personalizzato) |

| Certification standards | Ce, ISO4301, GB3811 |

Adaptive drum lifting beam: V-shaped saddle + adjustable clamp arm design, perfectly fits cable drums/steel coils of different diameters (Φ1m~Φ4m), eliminating the risk of slipping.

Rotating hook (360° continuous rotation): supports precise direction adjustment of the cable drum in the air to avoid damage caused by flipping on the ground.

Anti-flattening protection: The pressure sensor monitors the force on the hanging point in real time to prevent thin-walled coils from deforming (opzionale).

Quick change interface: compatible with C-type hooks, electromagnetic disks and other accessories, switching hoisting mode within 5 minutes.

Weihua i-Swing intelligent anti-sway system:

Active damping control based on AI algorithm, swing suppression ≥90% during start/stop.

Laser positioning + encoder feedback to achieve ±1mm repeatable positioning accuracy (suitable for docking narrow shelves/trucks).

Dual Speed/Variable Frequency Control Options:

Normal mode: 0~20m/min (efficient handling)

Micro movement mode: 0~1m/min (precise shaft threading, equipment in place)

FEM-M8 working level: higher durability than industry standard (M5), suitable for high-intensity continuous operations.

Reinforced wire rope system:

Anti-rotation rope core + zinc-nickel alloy coating (anti-wear and corrosion resistance).

The double spiral groove design of the drum prevents random rope hopping.

Hot-dip galvanizing or spray anti-corrosion: suitable for harsh environments such as acid fog in cable factories and outdoor substations (C4 protection level).

Dual brake redundant system: main brake (released when powered on) + backup mechanical brake, locked instantly when power is off.

Protezione da sovraccarico (110% alarm, 125% power off): prevent overload damage to the structure.

Limit triple protection: 1. Mechanical striker limit (forced cut-off); 2. Rotary encoder soft limit; 3. Absolute sensor redundancy check.

24V safety voltage control circuit: avoid the risk of electric leakage and injury (CE/ISO13849 certification).

IE4 high-efficiency motor + regenerative braking unit: feedback grid energy saving, energy consumption reduced by 30%.

Optional Weihua cloud monitoring system:

Real-time monitoring of load, motor temperature rise, and operating times.

Predictive maintenance reminders (rope life/brake pad wear).

Mobile APP remote fault diagnosis.

Pain point: The cable drum with a diameter of 3.2m and a weight of 32 tons needs to be loaded accurately, and manual hooking takes 30 minutes.

Weihua plan:

32 tons electric cable hoist + adaptive hanging beam.

I-Swing anti-sway system achieves ±5mm loading positioning.

Efficiency improvement: single lifting time ≤8 minutes.

Pain point: Precision equipment is placed in a narrow foundation pit (swaying can easily hit the wall).

Weihua plan:

50-ton low-headroom hoist + millimeter-level micro-movement mode.

Dual camera hook visualization system.

Successful case: ±0.5mm error completed 500kV transformer in place.

Pain point: The coil needs to be automatically connected to the pay-off machine.

Weihua plan:

Custom orbital paranco elettrico system.

Synchronized control with PLC to achieve fully automatic loading.

RFID identifies coil specifications and automatically adjusts the spreader.

Q:What is the difference between an electric cable hoist and an ordinary overhead crane?

UN:The core difference lies in the dedicated spreader + controllo preciso:

① Standard coiled material adaptive lifting beam (not ordinary lifting hook).

② Anti-shake accuracy is more than 5 times higher.

③ Reinforced structure to meet frequent full load operations (FEM-M8 level).

Q:Can an existing crane be retrofitted into a cable-specific hoisting system?

UN:Can! Weihua provides:

Q: How to protect the outdoor cable yard?

UN:Recommended configuration:

Q:How to prevent the insulation layer from being scratched when lifting the cable drum?

UN:Key measures:

① Use nylon-coated slings (not in direct contact with steel wire ropes).

② Add a polyurethane cushion pad to the suspension beam saddle.

③ Micro movement mode controls landing speed ≤0.3m/min.

Apprezziamo il tuo feedback! Completa il modulo sottostante in modo da poter personalizzare i nostri servizi alle tue esigenze specifiche.

Il paranco elettrico a catena WeiHua a bassa altezza è progettato specificamente per applicazioni dove……

Sei mai stato turbato da difficoltà durante le operazioni sul campo, siti di salvataggio, S……

Il paranco elettrico antideflagrante prodotto dal Gruppo Weihua ha superato la certificazione internazionale……

IL 5 Il paranco elettrico a catena da ton è un'attrezzatura di sollevamento efficiente e sicura appositamente desi……