An electric hoist is a powerhouse for lifting, but its true potential – and safety – hinge entirely on how and where you mount it. Choosing the right mounting solution isn't just about convenience; it's about structural integrity, 運用効率, and preventing dangerous accidents. Let's explore some of the most common and effective electric hoist mounting ideas:

オンラインチャットアイデア: Directly attaching the electric hoist trolley to a sturdy overhead structural steel I-beam or H-beam running the length of your desired lift path.

Pros:

Cons:

Requires suitable existing beams or significant structural modification/installation.

Fixed location; hoist travel is limited to the beam’s path.

Key Considerations:

アイデア: Mounting the hoist on a trolley that runs along a beam supported by two freestanding, adjustable-height legs (A-frames) on wheels or fixed bases.

Pros:

Cons:

Requires sufficient floor space for the base footprint and stability.

Load capacity is limited by the gantry frame’s rating (less than a fixed beam).

Wheels must be locked securely during lifting.

Key Considerations:

アイデア: Mounting a pivoting or fixed boom (jib arm) to a sturdy wall column or dedicated support structure, with the hoist running on a trolley along the boom.

Pros:

Cons:

Limited coverage area (defined by boom length and pivot arc).

Requires a very strong wall or dedicated foundation/pillar.

Can obstruct the wall area behind it.

Key Considerations:

アイデア: Mounting the hoist onto a dedicated trolley frame that itself runs along an overhead beam or monorail system. The hoist can lift, and the entire assembly can be moved horizontally.

Pros:

Cons:

Requires an existing compatible overhead track/rail system.

More complex setup.

Higher initial cost if installing the monorail.

Key Considerations:

アイデア: Building a custom-designed steel frame specifically to support the hoist and its trolley, independent of the building structure (though often anchored to the floor).

Pros:

Cons:

Highest cost and complexity.

Requires professional design and fabrication.

Consumes floor space.

Key Considerations:

Know Your Load Rating: これは交渉不可能です. The entire mounting system (beam, トロリー, bolts, structure, gantry legs, wall anchor) must be rated significantly higher than the hoist’s maximum capacity plus its own weight. Factor in dynamic loads (starting/stopping). Always use a safety factor (例えば。, 5:1).

Structural Integrity: Never guess. When in doubt about beams, walls, or foundations, consult a qualified structural engineer. Overloading a structure can lead to catastrophic failure.

Rated Hardware: Use only lifting-rated shackles, bolts, nuts, and washers. Standard hardware store bolts are NOT sufficient.

Electrical Safety: Ensure proper grounding and protection of power cables, especially where movement occurs (trolleys). Follow electrical codes.

Clearance: Ensure adequate headroom and path clearance for the load and hoist during travel.

Regular Inspection: Inspect all mounting points, hardware, 梁, and structures regularly for wear, ひび割れ, 変形, or corrosion.

The best mounting solution depends on your:

Application: What are you lifting? How often?

Workspace: Available ceiling height? Floor space? Existing beams/walls?

Required Coverage: Do you need a fixed point, linear travel, or area coverage?

Budget: From portable gantries to custom builds, costs vary significantly.

耐荷重: The primary driver for structural requirements.

Investing time and resources into selecting and implementing the correct electric hoist mounting solution is paramount. It ensures safety for personnel and equipment, maximizes the hoist’s efficiency and lifespan, and provides a reliable foundation for your lifting operations. Don’t cut corners – prioritize structural integrity and safety above all else. 迷ったときは, seek professional engineering advice. Lift smart, lift safe!

私たちはあなたのフィードバックを大切にします! あなたの特定のニーズに合わせてサービスを調整できるように、以下のフォームに記入してください.

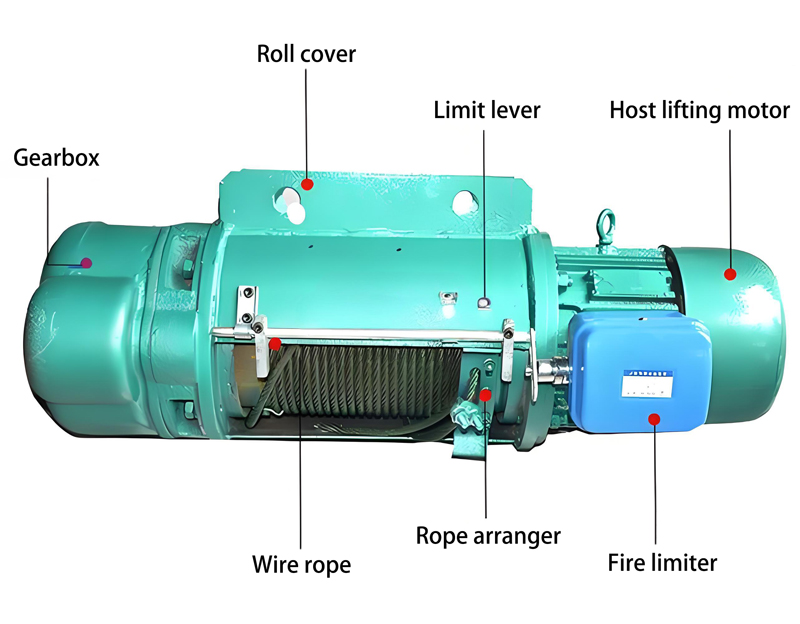

ブリッジ電動ホイストの製品特長 1. 堅牢な構造: 高強度の材料で作られています……

水輸送の急速な発展により, レジャーエンターテイメントとshipbuildi……

ミルウォーキー電気チェーン ホイストは、要求の厳しい産業用途向けに設計されています, ……

最大吊り上げ能力 4 トン, これ 4 トン電動ホイストはハンドラインに最適です……