モノレール電気ホイストトロリーはIビーム軌道に設置されており、ワイヤーロープ電気ホイストを駆動できます。, チェーン電気ホイスト, 左右にスライドするマイクロ電動ホイスト, 上下を簡単に認識, 材料の左右の取り扱い. しかし, 実際のアプリケーションでは, スポーツカーは時々ミスアライメントに遭遇することがあります, 機器の動作が悪くなったり、大きな騒音が発生したりする.

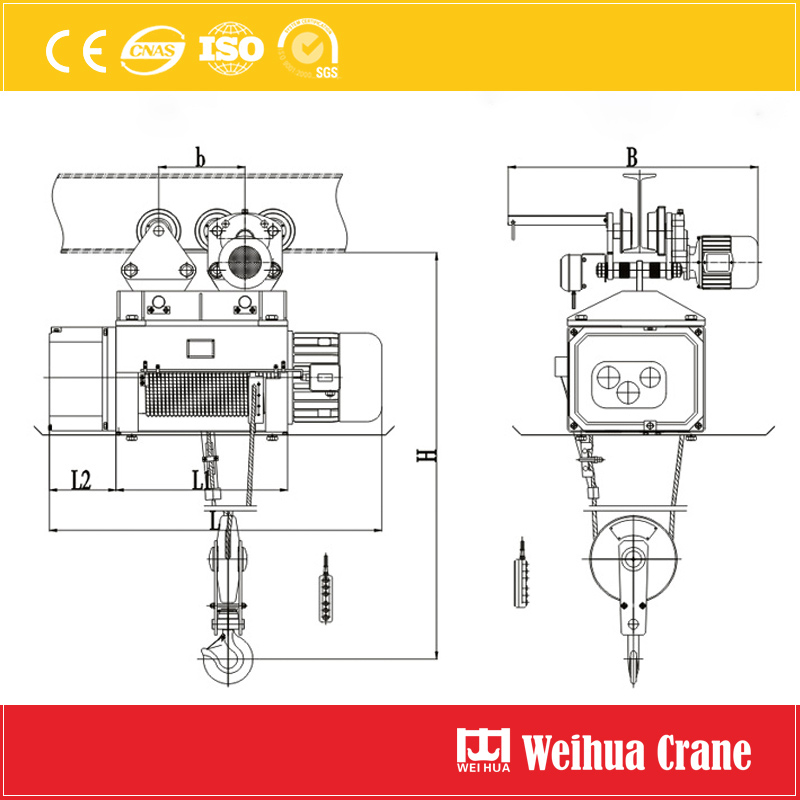

オンラインチャット使用するとき エレクトリックホイストトロリー, 私たちは基本的に、チェーン電気ホイストまたはワイヤロープ電気ホイストが I ビームまたはガントリー クレーンに吊り下げられるかどうかについて話します。. 使い切ることができます, 下, 左, そして正しい. The 爆発証明電気ホイスト トロリーは単独で設置する必要があります. 専門知識のない担当者は、トロリーの設置に多少の困難を感じる可能性があります。. 設置が不適切だと、運転中にトロリーがふらつくことがあります。. 曲がって持ち上げると, 重い物体は落ちます. これがどのようにして起こるのかを分析してみましょう.

理由分析:

線路の設置ずれ

トラック真直度誤差>3mm/m.

トラックジョイント部のズレ >2mm.

トラックレベル偏差>1/1000.

路面の異常

トラック踏面の油汚れ/錆 (摩擦係数の低減 30%+).

トラックトレッドの摩耗により形成された溝 (深さ > 1.5mm).

トラックプレッシャープレートのボルトが緩んでいる (仮締め力の損失 >20%).

解決:

軌道修正: レーザーセオドライトを使用して検出します, 6mごとのトラックセグメントの真直度を≤1.5mmに調整します。.

関節治療: フィッシュプレートを取り付けて滑らかに磨きます, ズレを0.5mm以内に抑制.

表面の洗浄: 油汚れの除去には金属系クリーナーを使用してください。, 錆びた部分を処理するワイヤーブラシ.

レール交換基準: 片側の摩耗量は以下に達します 10% 元の厚さの減少または疲労亀裂が発生する.

理由分析:

ホイールの偏摩耗

駆動輪と従動輪の直径の差は、 >2%.

リム片側の摩耗量は >5mm.

ホイールアライメント不良

車輪の水平振れ>1/1000ホイールベース.

縦振れ>車輪径1/400.

ベアリングの損傷

軸受すきま>0.5mm.

ケージが壊れて詰まりが発生する.

解決:

ホイールセットの調整:

テーパーゲージを使用してリム角度を検出します (標準 60°±5').

ホイールの水平振れを ≤0.5mm/m に調整します。.

ベアリングの交換:

C3クリアランスグレードベアリングを使用 (アキシアルクリアランス 0.12-0.25mm).

EP2 グレードのリチウム グリースを充填します。 (充填量が占める割合 60% 空洞の).

理由分析:

モーターが同期していない

デュアルドライブモーターの速度差>5%.

ブレーキ解除時間差>0.3s.

伝送システムの故障

減速機バックラッシ>0.15mm.

カップリング径偏差>0.1mm.

解決:

モーター同期校正:

ストロボスコープを使用して 2 つのモーター間の速度差を検出し、範囲内で制御します。 <2%.

インバータパラメータを調整する (キャリア周波数は 2 ~ 4kHz に設定されています).

トランスミッション系オーバーホール:

磨耗したギアを交換する (歯の厚みを減らす場合 >10%).

カップリングアライメント調整 (半径方向の誤差 ≤ 0.05mm).

特別なシナリオの質問:

オフセットロード動作: リフティングポイントオフセット >5% スパン.

風荷重の影響: 横風圧 >110N/㎡ (レベルに相当 6 風).

温度変形: トラックの温度差による熱膨張と収縮 >30℃.

対象を絞った対策:

自動補正システムを導入する:

レーザー変位計を線路の両側に設置 (精度±0.5mm).

PLCによる駆動モーターのトルク配分のリアルタイム調整.

温度補償トラックを使用する:

予備の伸縮継手 (8-12トラック30mごとにmmのギャップ).

低膨張係数鋼を使用 (CTE<11×10⁻⁶/℃).

日常点検:

ホイールとレールの隙間を毎週測定する (標準値 3~5mm).

トラックのスパン許容差を毎月確認します (±5mm許容).

予防保守:

減速機潤滑油は次の頻度で交換してください 2000 労働時間 (ISO VG320).

6 か月ごとの完全なシステム調整.

動作仕様:

引っ張ったり、斜めに持ち上げたりすることは禁止です (偏向角が0に達したらすぐに停止します。 >3°).

動作速度の制御 (重負荷時の定格速度の 60% 以下).

体系的な調査と緻密な調整により, の偏差 エレクトリックホイストトロリー ≤1/1000のスパン範囲内で効果的に制御可能. 動的負荷テストを次の範囲内で実施することをお勧めします。 72 電動ホイストトロリーの最初の設置から数時間後, 赤外線熱画像カメラを使用してホイールとレールの接触状態を監視します (温度差はこうあるべきです <15°C). 頻繁に徘徊する電動ホイストトロリに, 安定性を向上させるために電子揺れ防止システムを取り付けることをお勧めします.

私たちはあなたのフィードバックを大切にします! あなたの特定のニーズに合わせてサービスを調整できるように、以下のフォームに記入してください.

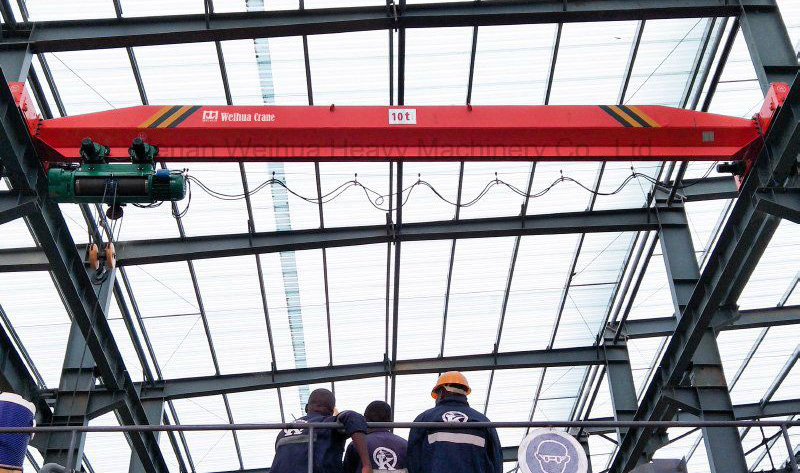

Weihua 壁掛け電動ホイストは、強力な電力を必要とする産業ユーザー向けに設計されています。

12 Tons Chain Hoist は単なるツールではなく、ダウンタイムに対する最前線の防御手段です, 安全……

Weihua Electric Hoistリモコンは、産業LIFのコア制御コンポーネントです……

Weihua の建設用電動ホイストは、…