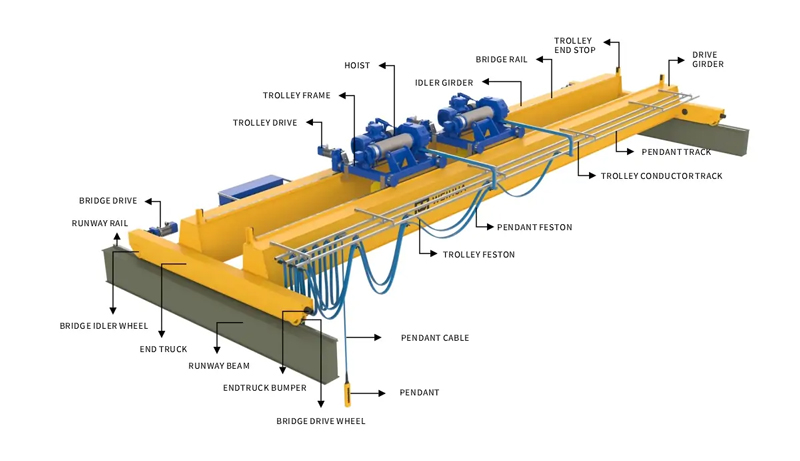

ダブルガーダートロリー電気ホイストは、高容量です。, ダブルガーダー天井クレーンとの統合向けに設計された産業グレードの吊り上げソリューション. この堅牢なシステムは、強力な機能を組み合わせています。 エレクトリックホイスト クレーンのツイン橋桁に沿って移動する電動トロリーに取り付けられます. 高い吊り上げ高さを必要とする過酷な用途向けに設計されています, 正確な荷重処理, 製鉄所などの要求の厳しい環境における卓越した信頼性, 製造店, 倉庫, そして鋳物工場. ワークスペースを最適化し、優れたフックアプローチを提供することにより、, 生産性と運用上の安全性を最大化します.

1. 高揚容量 & 義務クラス

ヘビーデューティおよび過酷なデューティサイクル向けに設計 (FEM 3M / 4m, クラスM6/M7).

からの負荷を処理可能 5 トンからオーバーまで 100 トン, 最も困難な産業作業に適しています.

2. 優れたフックアプローチ

二重桁システムの設計により、ホイストを桁の上に配置できます。, ヘッドルームを最小限に抑え、単一ガーダーシステムと比較して、クレーンガーダーにはるかに近いフックアプローチを提供します。. これにより、施設内で使用可能な昇降高さが最大化されます。.

3. 正確かつスムーズな制御

可変周波数制御を搭載 (VFD) 巻き上げ動作と横行動作の両方に対応. スムーズな加減速を実現します。, 正確なロードスポット, 負荷変動を軽減, 負荷と機器の両方を保護.

4. 安全性の強化 & 信頼性

5. モジュール式トロリーの設計

電動トロリーはクレーンガーダーに沿ってスムーズに移動できるように作られています。. オプションには、正確な位置決めのためのデュアルスピードまたは VFD 制御が含まれます. コンパクトなデザインにより優れた安定性と重量分散を実現.

6. メンテナンスが少ない & 耐久性

長い耐用年数を実現する高級スチールとプレミアムコンポーネントで作られています. メンテナンスポイントに簡単にアクセスできるため、検査と修理が簡素化されます, ダウンタイムの削減.

7. 知能制御システム

ペンダント押しボタンステーションまたは無線リモコンで操作可能. クレーン制御システム全体とのシームレスな統合により、調整された動作を実現します。.

注記: 次の表に一般的な仕様範囲を示します。. 正確なパラメータはモデルと容量によって異なります.

| 特徴 | 仕様範囲 | 詳細 |

| 持ち上げる容量 | 5 〜 100+ トン | まで利用可能な標準モデル 100 トン; 大容量向けのカスタム設計. |

| 高さを持ち上げる | まで 30 メーター (98 ft) | 要件に応じてカスタムの昇降高さを設計できます. |

| 持ち上げ速度 | 0.8 〜 15 m/my (デュアルスピード標準) | 速度は容量によって異なります; VFD により速度制御を調整可能. |

| トロリーの走行速度 | 5 〜 30 m/my (20 典型的なm/分) | VFD 制御によりトロリーの正確な位置決めが可能. |

| 義務クラス | FEM 3M, 4m (クラスM6, M7) | 重負荷および過酷な負荷のサイクルに適しています. |

| 電源 | 3-段階, 380V/415V, 50/60 Hz | 他の電圧も利用可能 (例えば。, 480v, 220v). |

| 周囲温度 | -20°C〜 +40°C | 高温または低温範囲に対応する特別な設計も可能. |

| 断熱クラス | クラスf / クラスh | モーターおよび電気システムに高い熱安定性を提供します. |

| 保護等級 | IP54 / IP55 (ホイスト & トロリー) | 粉塵や噴流水からの保護. |

| コントロール | ペンダント / ラジオリモート | 標準ペンダントケーブルの長さはカスタマイズ可能です. |

このダブルガーダートロリー電気ホイストは、特に次の用途に使用するように設計されています。:

1. ダブルガーダー天井クレーン: これは主要かつ最も一般的なアプリケーションです.

2. ガントリークレーン (二重桁): 二重箱桁設計が使用されているセミガントリークレーンまたはフルガントリークレーンに設置可能.

3. プロセスクレーン: 冶金における特殊な工業プロセスに最適, 鋳造, およびその他の重工業.

4. ワークショップクレーン: 重機を扱うための製造および組立ベイで使用されます, コンポーネント, と材料.

Q1: シングルガーダーホイストシステムとダブルガーダーホイストシステムの主な違いは何ですか?

a: 主な違いは構造です. 1 本の梁の下を 1 本のガーダーホイストが走行します, そのため、容量とフックの高さが制限されます. ダブルガーダーホイストは2つのトップランニングガーダーの間を走行します, より高い容量を提供する, より良いフックアプローチ, より高い持ち上げ高さ, より集中的な作業向けに構築されています, 精密な仕事.

Q2: 巻上・走行速度の調整はできますか?

a: はい. デュアルスピードが標準ですが, 可変周波数ドライブを強くお勧めします (VFD) 正確な制御のために. VFD により、ソフトスタート/ストップと無段階の速度調整が可能になります。, これは繊細な荷物の取り扱いや正確な位置決めに不可欠です.

Q3: どのような安全機能が標準装備されているか?

a: 標準の安全機能には通常、上限/下限リミット スイッチが含まれます, 過負荷制限装置, デュアルブレーキシステム (電磁 + 機械的), ペンダントの緊急停止ボタン. 衝突防止システムや回転フックブロックなどの追加の安全オプションも利用可能です.

Q4: ホイストのメンテナンスと整備はどのように行われますか?

a: メンテナンスは簡単です. 定期点検には目視検査が含まれます, ブレーキ機能の確認, ワイヤーロープの磨耗をチェックする, リミットスイッチが正しく動作することを確認します. 詳細なメンテナンスマニュアルの提供と、専門家による定期点検のサービス契約を提供しています。.

Q5: このホイストは特定の用途に合わせてカスタマイズできますか?

a: 絶対に. 幅広いカスタマイズオプションを提供しています, 特殊な揚程を含む, 容量, 速度, 電圧, および特定のデューティサイクル. 特殊なフックも提供できます, 腐食環境用の亜鉛メッキ仕上げ, または防爆バージョン.

詳細については, 技術データシート, またはお客様の特定のニーズに合わせたカスタム見積もり, 当社のエンジニアリング営業チームまでご連絡ください。. 私たちは、完璧なリフティングソリューションを見つけるお手伝いをします。.

私たちはあなたのフィードバックを大切にします! あなたの特定のニーズに合わせてサービスを調整できるように、以下のフォームに記入してください.

Weihua Groupが生産する防爆電気ホイストは国際規格に合格しました。

エレクトリックホイストを備えたガントリークレーンは、効率的で柔軟な材料ハンドリング機器です……

速いペースで, 現代の倉庫の厳しい環境, 効率, 安全性, そして ……

倉庫内, 工場, 世界中の組立ライン, 時間は究極の通貨です. た……