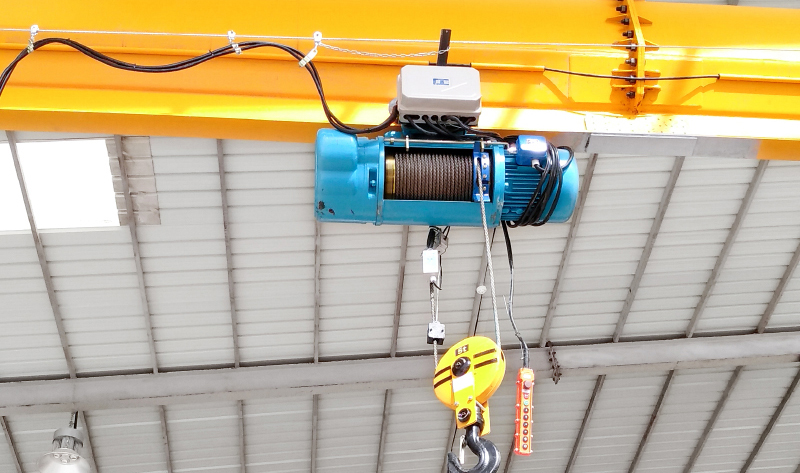

An electric hoist is a powerhouse for lifting, but its true potential – and safety – hinge entirely on how and where you mount it. Choosing the right mounting solution isn't just about convenience; it's about structural integrity, operational efficiency, and preventing dangerous accidents. Let's explore some of the most common and effective electric hoist mounting ideas:

온라인 채팅Idea: Directly attaching the electric hoist trolley to a sturdy overhead structural steel I-beam or H-beam running the length of your desired lift path.

Pros:

Cons:

Requires suitable existing beams or significant structural modification/installation.

고정 위치; hoist travel is limited to the beam’s path.

주요 고려 사항:

Idea: Mounting the hoist on a trolley that runs along a beam supported by two freestanding, adjustable-height legs (A-frames) on wheels or fixed bases.

Pros:

Cons:

Requires sufficient floor space for the base footprint and stability.

Load capacity is limited by the gantry frame’s rating (less than a fixed beam).

Wheels must be locked securely during lifting.

주요 고려 사항:

Idea: Mounting a pivoting or fixed boom (jib arm) to a sturdy wall column or dedicated support structure, with the hoist running on a trolley along the boom.

Pros:

Cons:

Limited coverage area (defined by boom length and pivot arc).

Requires a very strong wall or dedicated foundation/pillar.

Can obstruct the wall area behind it.

주요 고려 사항:

Idea: Mounting the hoist onto a dedicated trolley frame that itself runs along an overhead beam or monorail system. The hoist can lift, and the entire assembly can be moved horizontally.

Pros:

Cons:

Requires an existing compatible overhead track/rail system.

More complex setup.

Higher initial cost if installing the monorail.

주요 고려 사항:

Idea: Building a custom-designed steel frame specifically to support the hoist and its trolley, independent of the building structure (though often anchored to the floor).

Pros:

Cons:

Highest cost and complexity.

Requires professional design and fabrication.

Consumes floor space.

주요 고려 사항:

Know Your Load Rating: 이건 협상불가. The entire mounting system (빔, 트롤리, 볼트, structure, gantry legs, wall anchor) must be rated significantly higher than the hoist’s maximum capacity plus its own weight. Factor in dynamic loads (starting/stopping). Always use a safety factor (예를 들어, 5:1).

Structural Integrity: Never guess. When in doubt about beams, walls, or foundations, consult a qualified structural engineer. Overloading a structure can lead to catastrophic failure.

Rated Hardware: Use only lifting-rated shackles, 볼트, nuts, and washers. Standard hardware store bolts are NOT sufficient.

Electrical Safety: Ensure proper grounding and protection of power cables, especially where movement occurs (트롤리). Follow electrical codes.

Clearance: Ensure adequate headroom and path clearance for the load and hoist during travel.

Regular Inspection: Inspect all mounting points, hardware, 광선, and structures regularly for wear, 균열, 흉한 모습, or corrosion.

The best mounting solution depends on your:

애플리케이션: What are you lifting? How often?

Workspace: Available ceiling height? Floor space? Existing beams/walls?

Required Coverage: Do you need a fixed point, linear travel, or area coverage?

예산: From portable gantries to custom builds, costs vary significantly.

부하 용량: The primary driver for structural requirements.

Investing time and resources into selecting and implementing the correct electric hoist mounting solution is paramount. It ensures safety for personnel and equipment, maximizes the hoist’s efficiency and lifespan, and provides a reliable foundation for your lifting operations. Don’t cut corners – prioritize structural integrity and safety above all else. 의심스러울 때, seek professional engineering advice. Lift smart, lift safe!

우리는 귀하의 의견을 소중히 여깁니다! 귀하의 특정 요구에 맞게 서비스를 조정할 수 있도록 아래 양식을 작성하십시오..

WeiHua 로우 헤드룸 전기 체인 호이스트는 다음과 같은 용도로 특별히 설계되었습니다.

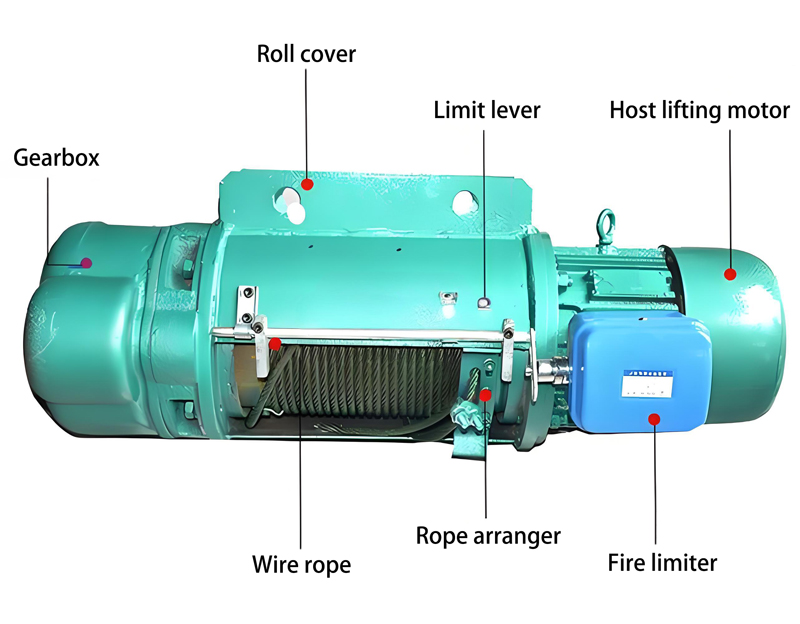

전선로프 호이스트의 핵심은 모터로 구성되어 있다, 감소 메커니즘, ……

제품소개 Double Girder Trolley Electric Hoist는 대용량입니다., 인더스…

Weihua의 Construction Electric Hoist는 고성능 리프팅 솔루션 엔지니어링 S ……