Is rope or cable better on a winch?

2025-06-06

The question "Rope or Cable?" is a classic debate in the world of winching. Whether you're recovering a vehicle, pulling equipment, or hauling materials, the choice between synthetic rope and steel cable on your winch matters. But before we dive into that, it's crucial to understand where winches themselves fit compared to their close cousins, electric chain hoists, especially when lifting loads vertically.

온라인 채팅

The choice of using ropes or cables on the winch needs to be determined based on specific needs and scenarios. Both have their own advantages and disadvantages.

윈치: Rope vs. 케이블

Assuming you’ve determined a winch is the right tool for your pulling job, let’s break down the rope vs. cable debate:

-

Steel Wire Cable (The Traditional Choice):

-

Pros:

- 내구성 & Abrasion Resistance: Extremely resistant to cuts, abrasion from rocks, 날카로운 모서리, and heat (like friction from a snatch block). Handles rough environments well.

- High Strength: Proven high tensile strength for heavy loads.

- UV Resistance: Not degraded by sunlight.

- Lower Stretch: Minimal elongation under load, providing more direct feel and control (though still some stretch exists).

-

Cons:

- 무게: Significantly heavier than synthetic rope, reducing effective pulling capacity slightly and making handling harder.

- Safety Hazard (Fraying & Snapping): When damaged, it frays into sharp, dangerous “fishhooks.” If it snaps under load, the recoil energy is massive and potentially lethal. Requires thick gloves.

- 부식: Can rust, especially in marine environments, requiring regular lubrication and inspection.

- Storage: Can develop “memory” and kinks, making it harder to wind smoothly onto the drum.

- Handling: Stiff and difficult to handle, especially when cold.

-

Synthetic Rope (Plasma®, Dyneema®, AmSteel® – The Modern Contender):

-

Pros:

- 안전: The biggest advantage. If it breaks, it drops to the ground with minimal recoil energy. No dangerous wire fragments.

- Lighter Weight: Dramatically lighter than steel cable, increasing effective winch pulling capacity and making handling much easier.

- Easier Handling: Softer, more flexible, and easier on the hands (gloves still recommended).

- Floats: Ideal for marine applications.

- No Corrosion: Immune to rust.

- Winds Smoother: Generally winds onto the drum more evenly than kinked cable.

-

Cons:

- Abrasion & Cut Vulnerability: Susceptible to damage from sharp rocks, edges, and heat (melts easily from friction). Requires protective sleeves (chafe guards) in abrasive situations.

- UV Degradation: Prolonged exposure to strong sunlight weakens it over time.

- Moisture Absorption: Can absorb water (especially if dirty), potentially freezing in cold weather and adding weight. Needs to dry.

- Stretch: More elongation under load than steel cable, though modern high-modulus fibers minimize this significantly compared to older synthetics. This can sometimes store energy like a spring.

- Inspection: Damage (internal or external) can be harder to spot than obvious kinks or broken strands in cable.

그래서, Which is “Better” for a Winch? There’s no single “best” answer; it depends entirely on your application.

-

Choose Steel Cable If:

- You frequently work in extremely abrasive environments (rock crawling, demolition debris).

- Heat generation (from prolonged winching or snatch blocks) is a major concern.

- UV exposure is constant and unavoidable.

- You prioritize maximum cut resistance above all else.

- Crucially, you understand and rigorously manage the safety risks (장갑, inspection, awareness of snap danger).

The difference between electric winch and electric chain hoist

-

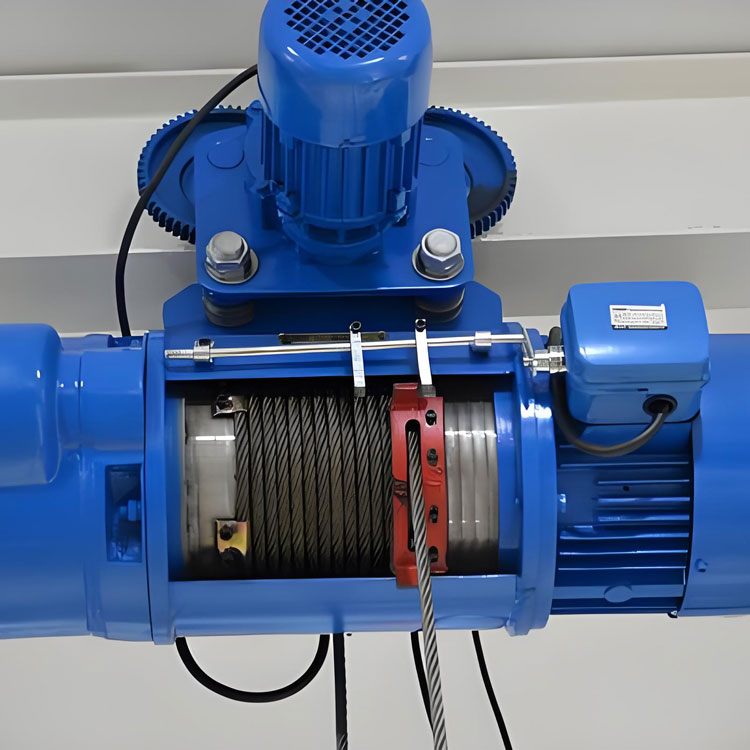

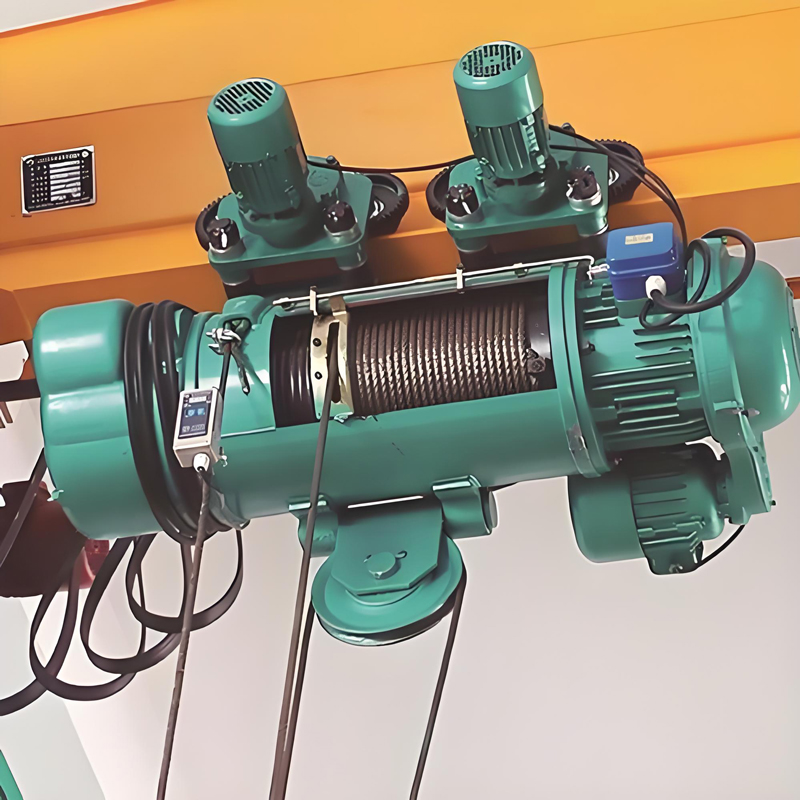

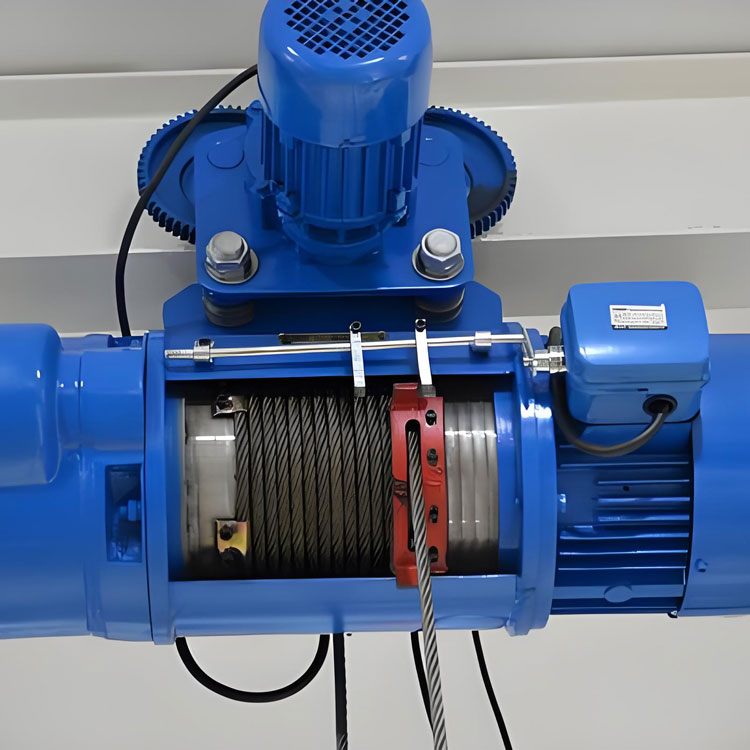

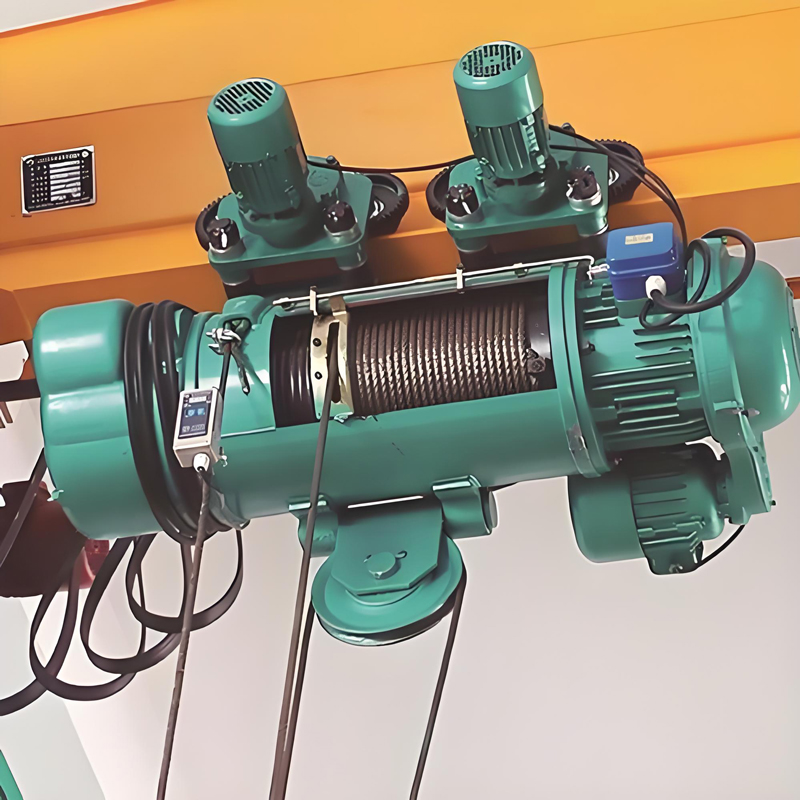

전기 체인 호이스트:

- Primary Function: Lifting and lowering loads vertically with precise control. Their design is optimized for overhead lifting.

- Lifting Element: Uses a durable, welded load chain (not rope or wire cable) that runs over a sprocket. The chain provides high strength in a compact form and inherently prevents rotation of the load.

- 정도: Offers excellent control for precise load positioning during lifting and lowering.

- Typical Uses: Factory assembly lines, 창고, machine shops, 유지보수 베이, 건설 현장 (lifting materials to height), stage rigging – anywhere controlled vertical movement is needed.

- 안전: Built with specific safety features (load brakes, 리미트 스위치) for overhead lifting applications. Often used with beam trolleys on runways.

The rope vs. cable decision for your winch hinges on your specific needs and risk tolerance. Synthetic rope offers compelling safety and handling advantages for most recreational and many industrial pulling applications, provided you protect it from abrasion. Steel cable remains the go-to for the toughest, most abrasive jobs where its durability outweighs the safety concerns. 기억하다, neither rope nor cable on a winch substitutes for the purpose-built welded load chain of an 전기 체인 호이스트 when the task involves safe, controlled overhead lifting. Always choose the right tool and the right line for the job, and prioritize safety above all else!