The metallurgical industry involves high-temperature operations such as steelmaking, iron smelting, and metal processing, where material handling equipment must endure extreme heat, 먼지, and heavy-duty cycles. Electric hoists play a crucial role in lifting molten metal, finished products, molds, and other heavy components efficiently and safely.

와이하, 중국의 주요 크레인 및 호이스트 제조업체, offers electric hoists specially engineered for metallurgical environments, delivering enhanced heat resistance, 안전 메커니즘, and operational reliability.

Weihua’s electric hoist for metallurgical use is designed specifically for lifting molten metal and other high-temperature materials in harsh environments. The hoist system adheres to the GB/T 3811-2008, JB/T 9008.1-2004, and other international standards, ensuring durability, 안전, and precise control.

고온 저항: Equipped with heat insulation plates and heat-proof wires, components are protected against temperatures up to 300°C.

Double Brake System: Features a mechanical and electromagnetic dual brake structure for enhanced operational safety.

과부하 보호: Intelligent monitoring and automatic shut-off in case of overload, preventing accidents and equipment damage.

정밀제어: Variable frequency drive (VFD) for smooth lifting and positioning of molten materials.

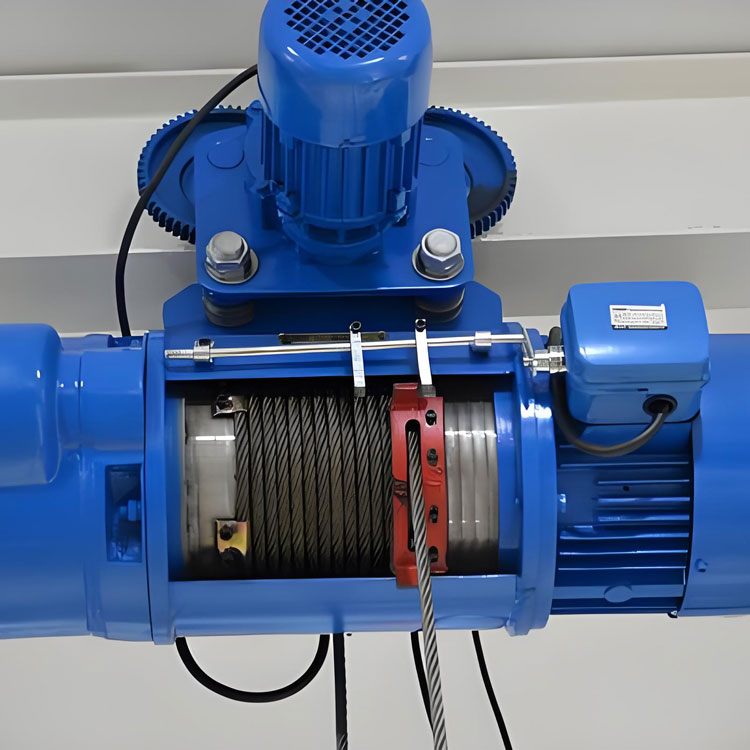

Heavy-Duty Design: High-strength steel wire ropes, thermal insulation gaskets, and Class H insulation motor.

Explosion-Proof Option Available: For environments with flammable gases or dust.

Safety Redundancy: Equipped with a limit switch, upper-lower position alarm, and temperature monitoring device.

| 모델 | 부하 용량 | 리프팅 높이 | 드는 속도 | 이동 속도 | 근무 의무 | 전원공급장치 | 주변 온도 | 절연 등급 |

| WH-MH5T | 5 톤 | 6-12m | 8 m/my (VFD) | 20 m/my | M6 | 3Ph, 380다섯, 50헤르츠 | -20°C to 300°C | 클래스 H |

| WH-MH10T | 10 톤 | 6–16 m | 7 m/my (VFD) | 20 m/my | M6 | 3Ph, 380다섯, 50헤르츠 | -20°C to 300°C | 클래스 H |

| WH-MH15T | 15 톤 | 6–20 m | 6 m/my (VFD) | 20 m/my | M7 | 3Ph, 380다섯, 50헤르츠 | -20°C to 300°C | 클래스 H |

| WH-MH20T (맞춤형) | 20 톤 | 6–24 m | 5 m/my (VFD) | 20 m/my | M7 | 3Ph, 380다섯, 50헤르츠 | -20°C to 300°C | 클래스 H |

메모: Custom specifications are available upon request, including anti-explosion features, 무선 원격 제어, and higher working duty classifications.

Optional Add-ons and Customization

1. Wireless remote control or semi-automatic control systems

2. 방폭 전기 호이스트 or flameproof models (Exd IIBT4, Exd IICT4 for Zone 1 & Zone 2)

3. Integration with overhead bridge cranes, ladle cranes, and automation systems

4. Load limiters, electronic weighing, and data recorders

Weihua’s metallurgical electric hoists are the result of decades of R&D and practical experience, especially in cooperation with large iron and steel enterprises. Key design innovations include:

1. Heat Shielding System: Multi-layer insulation system to protect electrical and mechanical components from radiant heat. The wire rope drum, hook block, and motor housing are thermally shielded with refractory materials.

2. Class H or Higher Insulation Motors: Motors with H-class insulation (up to 180°C tolerance), and optional water-cooled or forced-air cooling design for continuous duty.

3. Special Alloy Wire Rope: 열처리, corrosion-resistant wire ropes extend working life in high-temperature conditions.

4. Sealed Gearboxes and Bearings: Fully enclosed IP55–IP65 grade gearboxes and self-lubricated bearings extend lifespan and minimize maintenance even in dusty and humid plant conditions.

5. Programmable Logic Controller (PLC) 옵션: Smart monitoring of lifting load, temperature, brake condition, and usage cycles. Enables predictive maintenance and minimizes downtime.

Weihua delivered 12 sets of 10T metallurgical hoists to POSCO’s slab caster line. These hoists run at 95% duty cycle with thermal monitoring systems integrated into the plant’s MES (Manufacturing Execution System).

Weihua provided customized electric hoists with corrosion-resistant coatings and spark-proof components, essential for handling molten alloys and ore concentrates in a gold purification furnace environment.

Compact design 7.5T 낮은 헤드룸 전기 체인 호이스트 with trolleys enabled efficient operation under tight workshop constraints.

Weihua metallurgical electric hoists have been widely used in steel plants, foundries, aluminum refineries, and non-ferrous metal industries across multiple countries. Their reliability and robust build quality make them ideal for operations such as:

1. Handling molten iron in blast furnaces

2. Lifting ladles in continuous casting machines

3. Feeding raw materials into converters

4. Moving steel ingots, slabs, and coils

위에 35 years of crane and hoist manufacturing experience

ISO, CE, and SGS certified

Global service network and support

Proven reliability in high-temperature and heavy-load applications

Weihua’s electric hoist for metallurgical applications combines innovation, rugged engineering, and safety—making it the ideal choice for steel mills, smelting plants, and foundries worldwide. With tailored solutions, Weihua empowers metal industries to operate efficiently even in the harshest environments.

우리는 귀하의 의견을 소중히 여깁니다! 귀하의 특정 요구에 맞게 서비스를 조정할 수 있도록 아래 양식을 작성하십시오..

WeiHua 로우 헤드룸 전기 체인 호이스트는 다음과 같은 용도로 특별히 설계되었습니다.

20 FT 전기 케이블 호이스트 매개 변수 분류 매개 변수 이름 세부 기본 P ……

워크숍 운영을위한 안정적인 전기 호이스트를 찾고 있습니다? Weihua 's Electric Hoist i ……

그만큼 500 LB Electric Hoist는 Weihua Group이 개발 한 작은 전기 호이스트입니다., 잘 Kn ……