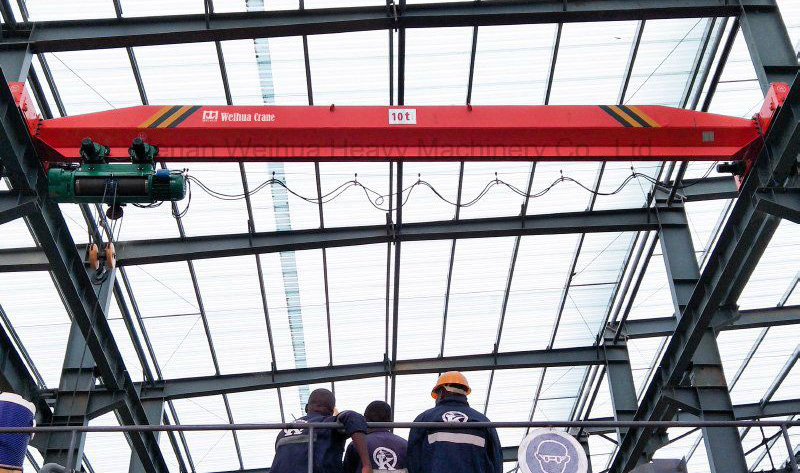

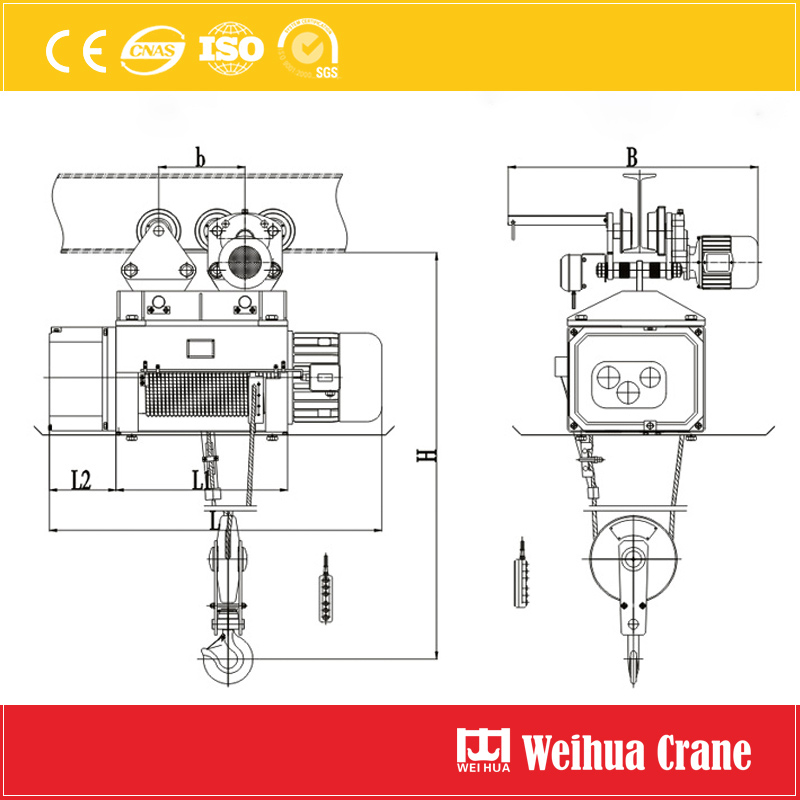

Troli angkat elektrik monorel dipasang di trek I-Beam dan boleh memandu tali wayar elektrik angkat, Rantaian elektrik berantai, dan angkat elektrik mikro untuk meluncur ke kiri dan kanan, mudah menyedari ke atas dan ke bawah, pengendalian bahan kiri dan kanan. Walau bagaimanapun, Dalam aplikasi praktikal, Kadang -kadang kereta sukan mungkin mengalami penyelewengan, menyebabkan peralatan berjalan buruk atau membuat bunyi keras.

Sembang dalam talianApabila kita menggunakan Troli angkat elektrik, Kami pada dasarnya bercakap tentang sama ada rantaian elektrik rantaian atau tali wayar elektrik hoists digantung pada beams atau kren gantri. Mereka boleh digunakan, ke bawah, kiri, dan betul. The Bukti letupan elektrik angkat elektrik troli perlu dipasang sendiri. Kakitangan yang tidak profesional akan menghadapi beberapa kesukaran memasang troli. Pemasangan yang tidak betul akan menyebabkan troli berjalan semasa operasi. Sekiranya ia diangkat dengan bengkok, objek berat akan jatuh. Mari kita menganalisis bagaimana ini disebabkan.

Analisis sebab:

Jejaki sisihan pemasangan

Jejaki kesilapan lurus > 3mm/m.

Misalignment di Track Bersama >2mm.

Penyimpangan tahap trek > 1/1000.

Anomali permukaan trek

Noda minyak/karat di tapak trek (Koefisien geseran dikurangkan oleh 30%+).

Alur terbentuk kerana dipakai di tapak trek (kedalaman > 1.5mm).

Bolt plat tekanan trek longgar (kehilangan kekuatan >20%).

Penyelesaian:

Pembetulan trek: Gunakan laser theodolite untuk mengesan, dan laraskan kelebihan setiap segmen trek 6m hingga ≤1.5mm.

Rawatan Bersama: Pasang ikan dan cat dengan lancar, dan mengawal misalignment dalam 0.5mm.

Pembersihan permukaan: Gunakan pembersih berasaskan logam untuk mengeluarkan kesan minyak, Berus kawat untuk merawat kawasan berkarat.

Piawaian penggantian kereta api: Jumlah haus di satu sisi mencapai 10% ketebalan asal atau keretakan keletihan muncul.

Analisis sebab:

Pakai roda yang tidak sekata

Perbezaan diameter antara roda memandu dan roda yang didorong adalah >2%.

Jumlah haus di satu sisi rim adalah >5mm.

Kegagalan penjajaran roda

Pesongan mendatar roda > 1/1000 roda jarak jauh.

Pesongan menegak > 1/400 diameter roda.

Kerosakan

Bearing Clearance > 0.5mm.

Sangkar patah menyebabkan jamming.

Penyelesaian:

Pelarasan set roda:

Gunakan tolok tirus untuk mengesan sudut rim (standard 60 ° ± 5 ').

Laraskan pesongan mendatar roda ke ≤0.5mm/m.

Penggantian galas:

Gunakan galas gred pelepasan C3 (Pelepasan paksi 0.12-0.25mm).

Isi dengan gris lithium gred EP2 (Mengisi akaun volum untuk 60% daripada rongga).

Analisis sebab:

Motor tidak selaras

Perbezaan Kelajuan Antara Dual Drive Motors > 5%.

Perbezaan Masa Pelepasan Brek > 0.3s.

Kegagalan sistem penghantaran

Reducer gear backlash > 0.15mm.

Penyimpangan radial gandingan > 0.1mm.

Penyelesaian:

Penentukuran Penyegerakan Motor:

Gunakan stroboskop untuk mengesan perbezaan kelajuan antara kedua -dua motor dan mengawalnya dalam <2%.

Laraskan parameter penyongsang (Kekerapan pembawa ditetapkan kepada 2-4khz).

Sistem penghantaran membaik pulih:

Ganti gear yang usang (Apabila pengurangan ketebalan gigi >10%).

Pelarasan penjajaran gandingan (Ralat radial ≤ 0.05mm).

Soalan Senario Khas:

Operasi beban mengimbangi: mengangkat titik mengimbangi >5% rentang.

Kesan beban angin: tekanan angin sisi >110N/m² (bersamaan dengan tahap 6 angin).

Ubah bentuk suhu: pengembangan terma dan penguncupan yang disebabkan oleh perbezaan suhu trek >30℃.

Langkah -langkah yang disasarkan:

Pasang sistem pembetulan automatik:

Pasang sensor anjakan laser di kedua -dua belah trek (Ketepatan ± 0.5mm).

Pelarasan masa nyata pengedaran tork motor pemacu melalui PLC.

Menggunakan trek pampasan suhu:

Rizab Pengembangan Rizab (8-12jurang mm untuk setiap 30m trek).

Gunakan keluli pekali pengembangan yang rendah (CTE < 11 × 10⁻⁶/℃).

Pemeriksaan harian:

Ukur pelepasan kereta api setiap minggu (Nilai standard 3-5mm).

Semak toleransi span trek setiap bulan (± 5mm dibenarkan).

Penyelenggaraan pencegahan:

Ganti pelincir reducer setiap 2000 jam kerja (Big VG320).

Penjajaran sistem penuh setiap enam bulan.

Spesifikasi operasi:

Dilarang menarik atau mengangkat pada sudut (berhenti sebaik sahaja sudut pesongan >3°).

Kawalan kelajuan operasi (≤60% kelajuan dinilai di bawah beban berat).

Melalui penyiasatan sistematik dan pelarasan yang tepat, Penyimpangan Troli angkat elektrik boleh dikawal dengan berkesan dalam julat rentang ≤1/1000. Disyorkan untuk menjalankan ujian beban dinamik dalam 72 beberapa jam selepas pemasangan awal troli angkat elektrik, dan gunakan kamera pengimejan haba inframerah untuk memantau status kenalan kereta api (perbezaan suhu mestilah <15° C.). Untuk troli angkat elektrik yang sering bersiar -siar, disyorkan untuk memasang sistem anti-sway elektronik untuk meningkatkan kestabilan.

Kami menghargai maklum balas anda! Sila lengkapkan borang di bawah supaya kami dapat menyesuaikan perkhidmatan kami dengan keperluan khusus anda.

Pengambilan Elektrik Pembinaan Weihua adalah penyelesaian pengangkat berprestasi tinggi yang direka bentuk ……

Di gudang, kilang, dan barisan perhimpunan di seluruh dunia, Masa adalah mata wang utama. T ……

Dalam keadaan pantas, menuntut persekitaran gudang moden, kecekapan, keselamatan, Dan ……

Weihua Headroom Headroom Electric Hoist direkayasa khusus untuk aplikasi wah ……