Pengangkat bot elektrik ialah peranti mekanikal yang digerakkan oleh motor elektrik, direka khas untuk mengangkat, memindahkan dan menyimpan vesel kecil dan sederhana (seperti kapal layar, perahu layar, bot laju, dll.). Fungsi terasnya adalah untuk menggantikan kren hidraulik atau manual tradisional untuk memberikan sokongan kuasa yang lebih tepat dan stabil sambil mengurangkan risiko operasi manual.

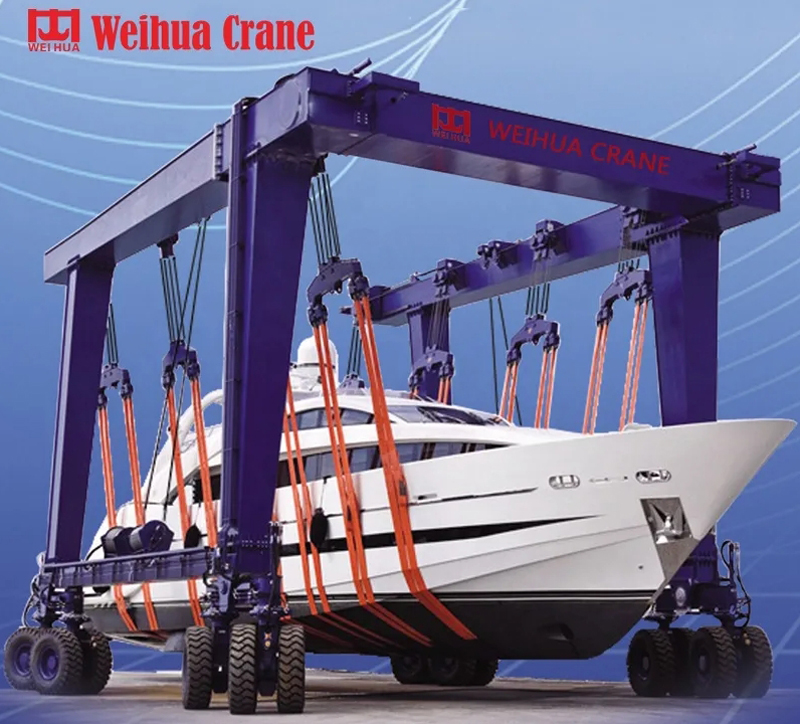

Dengan perkembangan pesat pengangkutan air, hiburan masa lapang dan industri pembinaan kapal, permintaan terhadap peralatan penyelenggaraan bot yang cekap dan mesra alam semakin meningkat dari hari ke hari. Sebagai peralatan mengangkat kapal moden, angkat bot elektrik secara beransur-ansur menjadi peralatan teras dok, limbungan kapal, kelab kapal layar dan tempat lain dengan operasi pintarnya, penjimatan tenaga, perlindungan alam sekitar dan ciri keselamatan yang tinggi.

Sistem pemacu menggunakan motor tork tinggi sebagai sumber kuasa, ditambah dengan pengurang dan kotak gear untuk mencapai pergerakan mengangkat lancar. Sesetengah model mewah menyokong peraturan kelajuan frekuensi berubah-ubah, dan kelajuan mengangkat boleh dilaraskan mengikut keperluan beban (selalunya 0.1-0.3 meter/saat).

Struktur menanggung beban

Sistem kawalan

Panel operasi: menyokong kawalan butang tempatan atau angkat elektrik dengan kawalan jauh tanpa wayar, dan beberapa model serasi dengan pengaturcaraan PLC atau pemantauan jauh APP mudah alih. Penderia keselamatan: Dilengkapi dengan perlindungan lebihan beban, brek kecemasan, suis had dan fungsi lain untuk mengelakkan terjatuh atau beban berlebihan secara tidak sengaja.

angkat bot elektrik

| Parameter | Spesifikasi biasa |

| Muatkan | 1 ton ~ 50 tan (disesuaikan atas permintaan), penyangkut diperbuat daripada keluli berkekuatan tinggi Q345B, permukaannya bergalvani celup panas, dan hayat rintangan kakisan adalah lebih daripada 15 tahun. |

| Angkat strok | Lejang standard ialah 3~15 meter, yang boleh dipanjangkan kepada 20 meter (sistem rel panduan tersuai diperlukan). |

| Spesifikasi kabel | Tali dawai keluli tergalvani anti putaran, diameter 12mm~28mm, ketegangan putus ≥180kN (tali tunggal). |

| Anduh / kurungan | Polietilena molekul tinggi (HMPE) anduh, lebar 200mm~400mm, Faktor keselamatan menanggung beban ≥6:1; kurungan badan kapal boleh disesuaikan untuk dibuat daripada aloi aluminium atau keluli tahan karat. |

| Jenis Motor | Motor tak segerak tiga fasa tork tinggi, kuasa terkadar 5.5kW~30kW (disesuaikan mengikut keperluan beban). |

| Konfigurasi kuasa | Voltan standard ialah 380V tiga fasa AC, bateri 220V fasa tunggal atau 48V DC pilihan (sesuai untuk senario tanpa grid kuasa). |

| Mengangkat kelajuan | 0.1~0.3 meter/saat (Peraturan kelajuan frekuensi berubah -ubah, menyokong perubahan kelajuan tanpa langkah). |

| Tahap perlindungan | IP67, kalis air dan debu, sesuai untuk persekitaran yang lembap dan menghakis semburan garam. |

| Mod operasi | Kawalan butang tempatan + Kawalan jauh tanpa wayar (angkat elektrik dengan kawalan jauh jarak 50 meter), kawalan pintar PLC pilihan atau pemantauan jauh APP mudah alih (4Rangkaian G/Wi-Fi). |

| Perlindungan keselamatan | Perlindungan pemadaman kuasa automatik yang berlebihan (dicetuskan apabila beban melebihi 110%).

Brek elektromagnet berganda + suis had mekanikal untuk mengelakkan terjatuh secara tidak sengaja. Butang berhenti kecemasan dan sistem diagnosis diri kerosakan (Skrin LED memaparkan kod ralat). |

| Ketepatan kedudukan | Ralat ketinggian mengangkat ≤±1cm, dilengkapi dengan sensor jarak laser. |

| Suhu kerja | -20℃~+60℃, sesuai untuk persekitaran iklim yang melampau. |

| Tahap rintangan angin | Operasi stabil di bawah kelajuan angin tahap 6 (13.8m/s). |

| Borang pemasangan | Jenis tetap (tertanam dalam asas konkrit) atau jenis mudah alih (roda universal berwajaran dengan peranti pengunci hidraulik). |

angkat bot elektrik

| Kapasiti beban | Pilih model berdasarkan berat kapal sasaran (termasuk peralatan tambahan), dan adalah disyorkan untuk menempah a 20% margin untuk menangani kecemasan. |

| Ketinggian dan kelajuan mengangkat | Sahkan sama ada strok peralatan memenuhi keperluan tapak. Model berkelajuan tinggi sesuai untuk senario operasi yang kerap. |

| Konfigurasi kuasa | Voltan biasa ialah 220V/380V, dan bateri atau versi hibrid solar adalah pilihan di kawasan terpencil. |

| Jenama dan Pensijilan | Beri keutamaan kepada jenama yang telah lulus pensijilan ISO dan CE untuk memastikan keselamatan dan sokongan selepas jualan. |

Arahan pengendalian

Penyelenggaraan tetap

angkat bot elektrik

Q1: Apakah kelebihan angkat bot elektrik berbanding dengan peralatan hidraulik tradisional?

A: Perlindungan alam sekitar dan penjimatan tenaga: pemacu elektrik mempunyai pelepasan sifar, penggunaan tenaga dikurangkan lebih daripada 40%, dan bunyinya ialah <65db.

Penyelenggaraan yang mudah: tiada minyak hidraulik diperlukan, mengurangkan risiko kebocoran, dan hanya pelinciran harian dan pemeriksaan litar diperlukan.

Kawalan yang tepat: Peraturan kelajuan penukaran kekerapan + kedudukan laser, ketepatan mengangkat sehingga ±1cm, sesuai untuk operasi ketepatan.

S2: Apakah keperluan untuk pemasangan peralatan?

A: Konfigurasi kuasa: ia perlu sepadan dengan voltan terkadar (seperti kuasa tiga fasa 380V), dan disyorkan untuk menempah kotak pengedaran bebas.

Keperluan asas: Pemasangan tetap memerlukan asas konkrit pra-benam (kedalaman ≥ 1.5 meter); pemasangan mudah alih memerlukan tanah yang licin dan keras.

Keperluan ruang: Rizab lebih daripada 1 meter ruang operasi selamat pada kedua-dua belah peralatan.

Q3: Bagaimana untuk memastikan ketahanan peralatan dalam persekitaran lembap?

A: Struktur teras diperbuat daripada keluli tergalvani celup panas, dengan motor terlindung IP67 dan komponen aloi anti-karat.

Permukaan tali dawai keluli tergalvani, dan kabel keluli tahan karat adalah pilihan (khas untuk persekitaran semburan garam tinggi).

Adalah disyorkan untuk sentiasa menyiram permukaan peralatan dengan air tawar dan menggunakan pelincir anti-karat.

Q4: Bagaimana untuk menangani beban angkat bot elektrik yang berlebihan?

A: Perlindungan automatik: sensor beban terbina dalam, secara automatik memotong kuasa dan mencetuskan penggera apabila beban melebihi had oleh 10%.

Brek dua kali ganda: brek elektromagnet + penguncian had mekanikal untuk mengelakkan terjatuh.

Operator perlu memunggah sebahagian daripada berat dengan segera dan menyemak status peralatan sebelum memulakan semula.

S5: Adakah ia menyokong keperluan tersuai?

A: Muatkan penyesuaian: model khas dari 1 ke 200 tan boleh direka (parameter kapal perlu disediakan terlebih dahulu).

Peluasan fungsi: Menyokong pemasangan pemantauan kamera, modul bekalan kuasa solar atau sistem penghantaran pintar.

Penyebar yang boleh disesuaikan: Menyediakan pelbagai pilihan penyebar seperti kurungan badan kapal, Sayap, gelung, dll.

S6: Apakah langkah-langkah yang diperlukan untuk penyelenggaraan harian angkat bot elektrik?

A: Pemeriksaan harian: memakai kabel, sendi longgar, tindak balas sistem kawalan.

Penyelenggaraan bulanan: pelincir rantai/rel, sensor bersih, menguji fungsi brek kecemasan.

Penyelenggaraan tahunan: Pasukan profesional memeriksa penebat, ubah bentuk struktur dan status salutan anti-karat motor.

Q7: Adakah peralatan lulus pensijilan keselamatan antarabangsa?

A: Produk ini telah lulus ISO 4301 (standard reka bentuk kren), Pensijilan CE dan Spesifikasi Keselamatan Teknikal China untuk Peralatan Khas (TSG).

Menyediakan laporan ujian pihak ketiga untuk memastikan pematuhan global.

Kami menghargai maklum balas anda! Sila lengkapkan borang di bawah supaya kami dapat menyesuaikan perkhidmatan kami dengan keperluan khusus anda.

Harbour Freight Electric Hoist adalah peralatan mengangkat berat yang direka khas untuk pelabuhan ……

Gambaran Keseluruhan Produk Tali wayar standard FEM angkat elektrik adalah liftin berprestasi tinggi ……

Dengan keupayaan mengangkat sehingga 4 tan, ini 4 Ton angkat elektrik sangat sesuai untuk handlin ……

Jadual Kandungan Tunjukkan ……