Project Overview and Significance

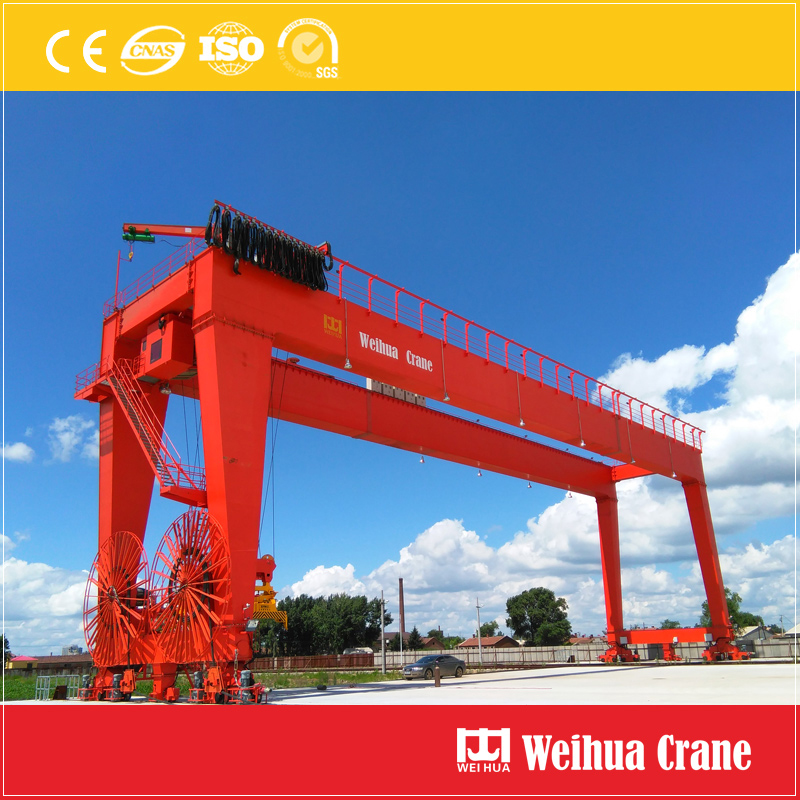

Indonesia, endowed with abundant water resources, has been vigorously advancing the development of hydropower projects as a core measure to optimize its energy structure and achieve carbon neutrality goals. A large-scale hydropower project situated in the central mountainous region of Indonesia is a key national infrastructure project, aiming to alleviate the local power shortage, drive regional industrial development, and improve people’s living standards. Recently, the project entered a critical construction phase, and the hoisting of core components has become a bottleneck restricting the construction progress. Weihua Group’s 100 тонн портальний кран, as the designated core hoisting equipment, was officially put into use, providing a solid guarantee for the smooth advancement of the project.

With the accelerating process of energy structure transformation in Indonesia, hydropower, as a clean and renewable energy source, has become a key part of the country’s energy development strategy. A large-scale hydropower project located in the central mountainous area of Indonesia, which is of great significance for improving the local power supply capacity, promoting regional economic development and reducing carbon emissions, recently achieved an important construction milestone. The core hoisting equipment supporting this project — a 100 tons gantry crane independently developed and manufactured by Weihua Group — has been put into stable operation, providing reliable hoisting guarantee for the project’s key construction links such as dam construction, turbine installation and steel structure hoisting.

Challenging Construction Environment and Equipment Requirements

The construction site of the Indonesian hydropower project is faced with multiple harsh environmental challenges. Located in a mountainous area, the terrain is undulating and steep, making transportation and equipment installation extremely difficult. Крім того, the region has a typical tropical monsoon climate, with high temperature and humidity, frequent heavy rains, and large temperature differences between day and night, which poses severe tests to the stability, corrosion resistance, and adaptability of hoisting equipment. Meanwhile, the project involves the hoisting of large-scale and high-precision components such as hydropower turbines, generators, and dam prefabricated parts, with single-component weights ranging from 80 до 100 тонн. These components have strict requirements on hoisting accuracy and safety, requiring the hoisting equipment to have excellent load-bearing capacity, precise control performance, and comprehensive safety protection functions. After rigorous screening and technical demonstration by the project party, Вейхуа 100 tons gantry crane stood out due to its outstanding product performance and rich experience in similar projects.

Weihua 100-ton Gantry Crane: Customized Optimization for the Project

In response to the specific needs of the Indonesian hydropower project, Weihua’s R&D and technical team carried out in-depth customization and optimization of the 100 тонн портальний кран. In terms of structural design, the crane adopts a modular split structure, which can be disassembled into multiple small components for transportation, effectively solving the problem of difficult transportation in mountainous areas. After arriving at the site, the modular assembly can be completed quickly, greatly shortening the installation cycle. The main beam and support frame are made of high-strength weather-resistant steel, which has undergone anti-corrosion treatment, enabling the crane to resist the erosion of high temperature, вологість, and rainwater, and ensuring long-term stable operation in harsh environments. In terms of control system, the crane is equipped with a fully automatic intelligent control system, which integrates advanced technologies such as PLC control and frequency conversion speed regulation. It can realize precise control of hoisting speed, висота підйому, and lateral movement, with a positioning accuracy of up to ±3mm, fully meeting the high-precision hoisting requirements of core components. In terms of safety protection, the crane is equipped with a multi-level safety protection system, включаючи захист від перевантаження, over-limit protection, anti-collision protection, and emergency braking. Once an abnormal situation occurs during operation, the system can automatically alarm and stop the machine, maximizing the safety of personnel and equipment.

Excellent Application Performance and Project Contributions

Since its official commissioning, Вейхуа 100 tons gantry crane has performed excellently in the project construction. It has successfully completed the hoisting tasks of more than 20 core components such as hydropower turbines and generators, with a 100% success rate in hoisting. The precise positioning performance of the crane has effectively ensured the installation quality of the components, avoiding rework caused by installation deviations. At the same time, the efficient operation of the crane has significantly improved the construction progress. Compared with the original plan, the hoisting work cycle has been shortened by 20%, effectively driving the overall progress of the project. In the face of frequent heavy rains and high-temperature weather, the crane has maintained stable operation without any failure, fully demonstrating its strong environmental adaptability. The outstanding performance of the crane has won high praise from the project party and the construction unit, who commented that Weihua’s gantry crane is a reliable “assistant” for the smooth progress of the project.

Weihua’s Global Layout and Industry Value

As a global leader in the hoisting equipment industry, Weihua Group has always adhered to the development strategy of “technology-driven and global layout”, and has provided high-quality hoisting solutions for hundreds of large-scale projects around the world. The successful application of the 100 tons gantry crane in the Indonesian hydropower project is another important achievement of Weihua’s products going global, which not only demonstrates Weihua’s strong R&D capabilities and manufacturing strength, but also further enhances Weihua’s brand influence in the Southeast Asian market. In the future, Weihua Group will continue to focus on technological innovation, closely follow the development needs of global infrastructure and energy projects, develop more high-performance, high-reliability hoisting equipment, and make greater contributions to promoting global energy transformation and infrastructure construction.