In the high-stakes world of metal fabrication, where precision meets brute force and deadlines loom large, efficiency and safety aren't just goals – they're the bedrock of profitability and survival. And when it comes to moving heavy plate, positioning complex weldments, or loading finished products, the electric hoist emerges as an indispensable powerhouse. More than just a convenience, it's a strategic investment that transforms your shop floor operations.

Trò chuyện trực tuyếnĐã qua rồi những ngày (hoặc họ nên!) chỉ dựa vào sức lao động chân tay mỏi mệt hoặc những dây xích cồng kềnh cho mỗi lần nâng. Hoạt vận động điện bring a level of power, control, and repeatability that manual methods simply cannot match, addressing the core challenges of a metal fabrication shop:

1. Taming the Tonnage: From thick steel plate and structural beams to massive machinery and completed fabrications, metal is heavy. Electric hoists effortlessly handle capacities ranging from a few hundred pounds to several tons, lifting loads that would be unsafe or impossible for personnel.

2. Precision Placement: Welding, gia công, and assembly demand pinpoint accuracy. Electric hoists offer smooth, controlled lifting and lowering, allowing operators to position components exactly where they need to be – crucial for fit-up, căn chỉnh, and quality control.

3. Supercharging Productivity: Time is money. Electric hoists drastically reduce the time spent moving materials between cutting, bending, welding, and assembly stations. What took minutes with manual methods takes seconds with an electric hoist. This frees up skilled labor for value-added tasks.

4. An toàn là trên hết, Always: Manual handling of heavy metal objects is a primary cause of shop floor injuries – strains, sprains, crush injuries, and worse. Electric hoists remove workers from the direct line of fire. Robust safety features like overload protection, dừng khẩn cấp, and fail-safe brakes create a significantly safer work environment, reducing accidents and associated costs (workers’ comp, downtime).

5. Operator Ergonomics: Reducing physical strain isn’t just about safety; it’s about preventing fatigue. Operators using electric hoists work smarter, not harder, leading to better focus, fewer errors, and higher morale.

6. Versatility is Key: Electric hoists integrate seamlessly into various shop setups:

Cầu Cẩu: The ultimate solution for covering large areas of the shop floor.

Cần cẩu Jib: Perfect for workstation-specific lifting (VÍ DỤ., near a press brake, welding cell, or saw).

Cần cẩu giàn với vận thăng điện: Excellent for outdoor yards, bến cảng tải, or areas without permanent overhead support.

Monorails: For moving loads along a fixed path between stations.

Not all hoists are created equal for the demanding environment of metal fabrication. Consider these critical factors:

1. Dung tích: Determine the maximum weight you need to lift regularly. Don’t forget to factor in the weight of lifting attachments (cáp treo, magnets, thanh rải). Always choose a capacity with a safety margin.

2. Chiều cao nâng: Measure the distance from the lowest hook point to the highest required lift point under your crane or jib.

3. Chu kỳ nhiệm vụ (CMAA Class): Metal fabrication shops often require frequent lifting. Look for hoists rated for higher duty cycles (VÍ DỤ., CMAA Class D – Heavy Duty or Class E – Severe Duty) to withstand constant use without premature wear. Cheaper, light-duty hoists won’t last.

4. Môi trường: Consider exposure to:

Heat: Near welding or cutting areas? Ensure the hoist has adequate heat resistance.

Dust & Debris: Grinding and cutting generate particles. Look for hoists with good ingress protection (IP ratings) or consider enclosed hoists.

Corrosive Elements: Certain processes or chemicals might require stainless steel components or special coatings.

5. Điều khiển: Điều khiển mặt dây chuyền là tiêu chuẩn. Look for ergonomic designs and features like variable speed control for delicate positioning. Radio remote controls offer greater operator mobility and visibility, especially useful for large lifts or awkward positions.

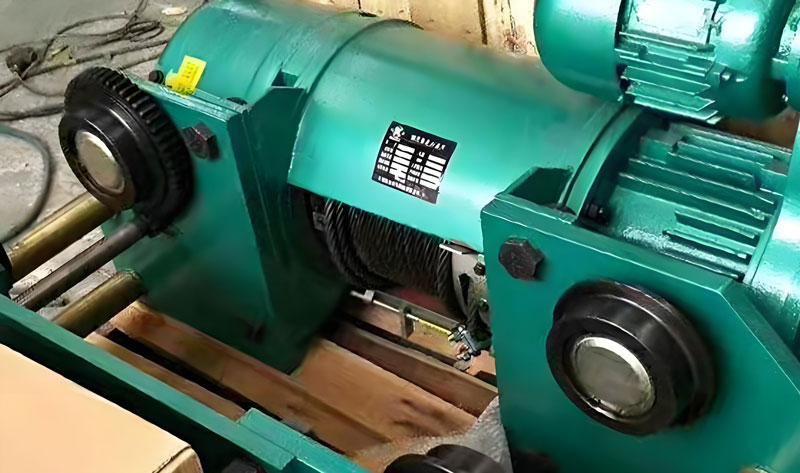

6. Loại tời: Wire rope hoists generally offer higher capacities and greater durability for rugged fab shop environments. Chain hoists can be more compact and economical for lighter, less frequent tasks.

7. Tính năng an toàn: không thể thương lượng. Must include overload limit switch, công tắc giới hạn trên/dưới, dừng khẩn cấp, bảo vệ quá tải nhiệt, and fail-safe braking.

8. Lifting Attachments: Match the hoist to the tools you need: plate magnets, C-hooks, beam clamps, lifting tongs, or specialized fixtures.

Investing in quality electric hoists delivers tangible returns:

1. Giảm chi phí lao động: Move more material with fewer people.

2. Faster Throughput: Get jobs through the shop quicker.

3. Minimized Damage: Precise handling prevents costly damage to materials and finished products.

4. Lower Injury Rates & Costs: A safer shop saves money and protects your workforce.

5. Improved Quality: Better positioning leads to better welds and assemblies.

6. Enhanced Shop Capacity: Handle larger, heavier projects you might have previously turned away.

An electric hoist isn’t just a piece of equipment; it’s a force multiplier for your metal fabrication shop. It empowers your workforce, safeguards their well-being, accelerates production, and ultimately boosts your bottom line. By carefully selecting the right hoist for your specific needs and environment, you’re not just lifting metal – you’re elevating your entire operation to a new level of efficiency, sự an toàn, and competitiveness.

Chúng tôi coi trọng phản hồi của bạn! Vui lòng hoàn thành biểu mẫu bên dưới để chúng tôi có thể điều chỉnh các dịch vụ của mình theo nhu cầu cụ thể của bạn.

Tại sao nên chọn tời điện Weihua để tháo động cơ? Palăng động cơ truyền thống (anh đào……

Trong lắp đặt thiết bị điện, sản xuất cáp và vận chuyển vật liệu nặng, cái hô……

8 Các tính năng chính của Palăng xích điện & Những lợi ích 1. Nâng công suất cao: A tr……

Palăng điện xây dựng của Weihua là giải pháp nâng hiệu suất cao được thiết kế s……