Trong thế giới nâng vật nặng, hai người kiên cường thường đứng cạnh nhau trong xưởng, Kho, và các công trường xây dựng: Palăng điện và Palăng xích thủ công (thường được gọi đơn giản là Palăng xích hoặc Khối xích). Mặc dù cả hai đều phục vụ mục đích cơ bản là nâng theo phương thẳng đứng, hoạt động của họ, khả năng, và các ứng dụng lý tưởng khác nhau đáng kể. Chọn sai có thể có nghĩa là kém hiệu quả, sự mệt mỏi của người vận hành, hoặc thậm chí không đủ năng lượng. Hãy chia nhỏ những khác biệt chính.

Trò chuyện trực tuyến

1. Nguồn điện & Hoạt động:

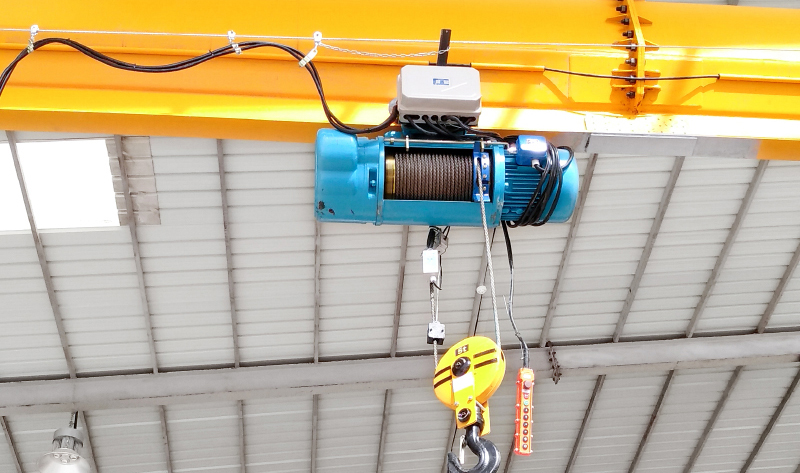

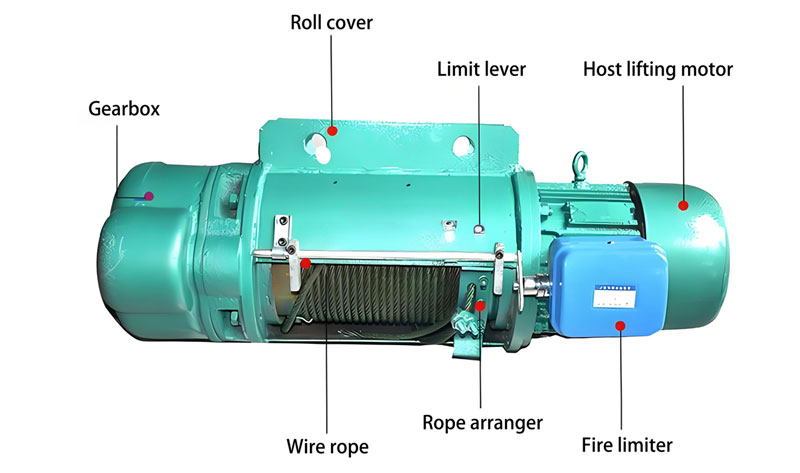

Hoạt vận động điện: Chạy bằng động cơ điện. Hoạt động thường thông qua điều khiển mặt dây chuyền bằng nút nhấn (lên/xuống) hoặc đôi khi là một chiếc điều khiển từ xa bằng radio. Yêu cầu một nguồn điện đáng tin cậy (một pha hoặc ba pha, tùy thuộc vào mô hình).

Palăng xích: Được hỗ trợ hoàn toàn bởi nỗ lực của con người. Người vận hành kéo xích tay theo một hướng để nâng và hướng còn lại để hạ tải. Không cần điện.

2. Tốc độ nâng & Hiệu quả:

Hoạt vận động điện: Tốc độ nâng và hạ nhanh hơn đáng kể. Lý tưởng cho các nhiệm vụ nâng lặp đi lặp lại, hoạt động khối lượng lớn, hoặc di chuyển tải trên khoảng cách lớn hơn một cách nhanh chóng. Tăng năng suất đáng kể.

Palăng xích: Tốc độ nâng tương đối chậm, hoàn toàn phụ thuộc vào sức mạnh và sức chịu đựng của người vận hành. Phù hợp nhất cho thang máy thường xuyên, định vị chính xác, hoặc các nhiệm vụ tần số thấp hơn. Có thể gây mệt mỏi cho người vận hành khi sử dụng nhiều hoặc thường xuyên.

3. Sức nâng:

Hoạt vận động điện: Có sẵn trong một loạt các công suất, từ công việc nhẹ (VÍ DỤ., 250 kg / 0.25 tấn) cho đến những mẫu xe có tải trọng cực lớn (50 tấn+). Dễ dàng xử lý công suất lớn hơn một cách hiệu quả.

Palăng xích: Cũng có sẵn trong một loạt các công suất (VÍ DỤ., 500 kg đến 20 tấn+ chung). Tuy nhiên, năng lực thực tế thường bị hạn chế bởi khả năng kéo xích hiệu quả của người vận hành, đặc biệt là gần định mức tối đa của vận thăng. Các mô hình công suất rất cao đòi hỏi nỗ lực rất lớn.

4. Điều khiển & Độ chính xác:

Hoạt vận động điện: Cung cấp khả năng kiểm soát tốt thông qua động cơ có tốc độ thay đổi (trên nhiều mẫu) để khởi động/dừng và định vị trơn tru. Dễ dàng hoạt động nhất quán hơn. Tuy nhiên, Kiểm soát “inch” tốt có thể yêu cầu các tính năng cụ thể.

Palăng xích: Cung cấp phản hồi xúc giác tuyệt vời và khả năng kiểm soát rất tốt để định vị chính xác (VÍ DỤ., máy móc phù hợp, sắp xếp các thành phần). Người vận hành trực tiếp cảm nhận được tải trọng.

5. Cài đặt & Yêu cầu:

Hoạt vận động điện: Yêu cầu hệ thống dây điện phù hợp và thường có cấu trúc hỗ trợ chắc chắn (chùm tia, xe đẩy, giàn) do tốc độ cao hơn và lực động tiềm tàng. Việc lắp đặt thường phức tạp hơn và đòi hỏi nhân viên có trình độ.

Palăng xích: Cài đặt đơn giản hơn. Chủ yếu cần một điểm neo phù hợp (cái móc, tai) trên dầm hoặc kết cấu. Tính di động cao – dễ dàng di chuyển đến các địa điểm khác nhau.

6. Cân nhắc chi phí:

Hoạt vận động điện: Chi phí mua ban đầu cao hơn. Đòi hỏi chi phí điện liên tục. Tiềm năng chi phí bảo trì cao hơn do động cơ, hộp số, và linh kiện điện.

Palăng xích: Chi phí mua ban đầu thấp hơn. Không có chi phí năng lượng vận hành (vượt quá lượng calo của người vận hành!). Nói chung chi phí bảo trì thấp hơn (Bánh răng, Vòng bi, xích).

7. Tiếng ồn & Môi trường:

Hoạt vận động điện: Tạo ra tiếng ồn từ động cơ và hộp số trong quá trình vận hành.

Palăng xích: Hoạt động âm thầm (ngoài âm thanh chuyển động của dây chuyền).

8. Tính năng an toàn:

Cả hai: Nên có các tính năng an toàn thiết yếu như bộ hạn chế tải/bảo vệ quá tải và phanh cơ. Hoạt vận động điện thường bao gồm các tính năng bổ sung như nút dừng khẩn cấp, bảo vệ pha, và bảo vệ quá tải nhiệt cho động cơ. Sự an toàn của pa lăng xích chủ yếu phụ thuộc vào việc người vận hành sử dụng đúng cách và không vượt quá công suất.

1. Tần số cao, nhiệm vụ nâng lặp đi lặp lại.

2. Nâng tải nặng hiệu quả.

3. Các ứng dụng yêu cầu tốc độ nâng/hạ nhanh hơn.

4. Các tình huống mà người vận hành cần giảm thiểu sự mệt mỏi.

5. Tích hợp vào dây chuyền sản xuất hoặc quy trình tự động.

6. Nâng trên độ cao lớn hơn thường xuyên.

1. Nhu cầu nâng thường xuyên.

2. Nhiệm vụ định vị chính xác (lắp đặt máy móc, căn chỉnh).

3. Các ứng dụng không có điện, không đáng tin cậy, hoặc nguy hiểm.

4. Thang máy có công suất thấp hơn nơi nỗ lực của người vận hành có thể quản lý được.

5. Các dự án phù hợp với ngân sách.

6. Các tình huống yêu cầu tính di động cao và thiết lập nhanh chóng ở các vị trí khác nhau.

7. Cửa hàng bảo trì, xưởng nhỏ hơn, công việc hiện trường.

Không có tời nâng nào “tốt nhất”. Sự lựa chọn đúng đắn hoàn toàn phụ thuộc vào nhu cầu cụ thể của bạn:

1. Tải trọng lượng & Tính thường xuyên: nặng bao nhiêu, bao lâu một lần?

2. Chiều cao nâng & Tốc độ cần thiết: Bao xa, nhanh như thế nào?

3. Nguồn điện sẵn có: Nguồn điện ổn định tại chỗ?

4. Yêu cầu về độ chính xác: Cần kiểm soát tốt?

5. Ngân sách: Chi phí ban đầu so với. chi phí hoạt động dài hạn?

6. Tính di động: Cần phải di chuyển nó thường xuyên?

7. Môi trường: bụi bặm, ướt, bầu không khí bùng nổ? (Yêu cầu xếp hạng cụ thể).

Bằng cách cân nhắc cẩn thận các yếu tố này so với điểm mạnh và điểm yếu của tời điện và tời xích, bạn có thể tự tin lựa chọn dụng cụ nâng hạ mang lại sự an toàn tối đa, hiệu quả, và giá trị cho ứng dụng cụ thể của bạn. Nhớ, đôi khi có một trong số đó là giải pháp hoàn hảo cho một không gian làm việc linh hoạt!

A1: Cả hai đều có phạm vi công suất tương tự nhau (VÍ DỤ., 0.5–20+ tấn). Tuy nhiên, tời điện xử lý tải nặng hiệu quả mà không gây căng thẳng cho người vận hành, trong khi pa lăng xích thủ công phụ thuộc vào nỗ lực của con người (làm cho tải rất nặng không thực tế để sử dụng thường xuyên).

A2: Lý tưởng cho:

1. Nâng thường xuyên/lặp đi lặp lại.

2. Tải nặng (1+ tấn).

3. Nhiệm vụ đòi hỏi tốc độ hoặc sự mệt mỏi tối thiểu của người vận hành.

4. Dây chuyền sản xuất hoặc cài đặt tự động.

A3: Chọn thời điểm:

1. Định vị chính xác là rất quan trọng (VÍ DỤ., căn chỉnh máy móc).

2. Không có điện hoặc nguy hiểm.

3. Tính di động, chi phí thấp, hoặc sử dụng không thường xuyên được ưu tiên.

4. Tải nhẹ hơn hoặc nâng không thường xuyên.

Chúng tôi coi trọng phản hồi của bạn! Vui lòng hoàn thành biểu mẫu bên dưới để chúng tôi có thể điều chỉnh các dịch vụ của mình theo nhu cầu cụ thể của bạn.

Palăng điện gắn trần Weihua có hộp điện nhỏ gọn và khoảng không thấp……

Xe nâng tời điện là giải pháp hiệu quả, an toàn, thiết bị nâng nhẹ và nhỏ. Com……

Vỏ chống cháy nổ tời điện, linh kiện điện chính xác, và nâng cao li……

Weihha 2000 Palăng điện pound kết hợp kinh nghiệm tích lũy nhiều năm của Weihua……