In hazardous environments such as the oil and gas industry, safety and reliability are paramount. Operations in these sectors often involve flammable gases, vapors, or combustible dust, which makes the use of standard lifting equipment risky. This is where explosion-proof electric hoists come into play—designed specifically to meet the strict safety standards of hazardous work zones.

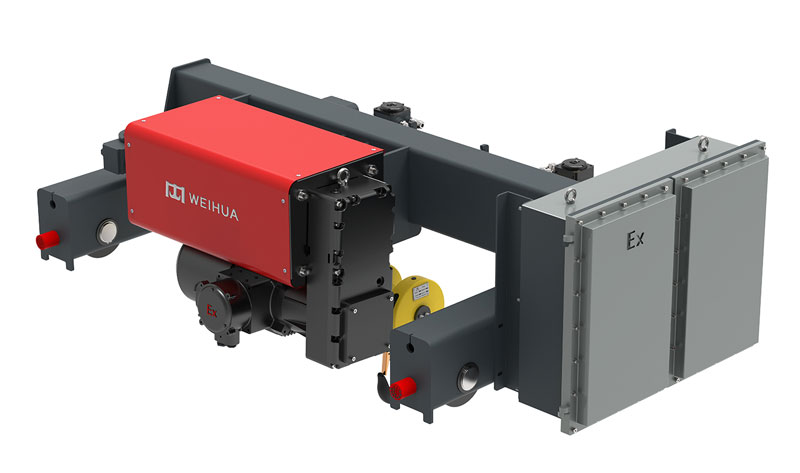

Trò chuyện trực tuyếnMỘT Palăng điện chống cháy nổ is a specialized lifting device equipped with features that prevent ignition of the surrounding atmosphere. These hoists are constructed with flameproof enclosures, spark-proof materials, and sealed electrical components. Their motors, switches, and wiring are designed to contain any sparks or explosions within the unit, preventing them from igniting flammable substances in the environment.

The oil and gas industry involves upstream (exploration and drilling), midstream (transportation and storage), and downstream (refining and distribution) hoạt động, all of which require safe and efficient material handling. Explosion-proof electric hoists are used in:

1. Offshore drilling platforms

2. Onshore oilfields

3. Gas processing plants

4. Petrochemical refineries

5. Tank farms and pipelines

These hoists are ideal for lifting heavy machinery, đường ống, valves, and maintenance tools in confined or hazardous spaces.

Explosion-proof electric hoists offer a range of features tailored to high-risk industrial environments:

1. Explosion-proof motor and controls certified for Zone 1 and Zone 2 khu vực nguy hiểm

2. Flameproof enclosures made from cast aluminum or ductile iron

3. Corrosion-resistant finishes suitable for offshore and harsh environments

4. Precision control systems for smooth lifting and lowering

5. Overload protection and emergency stop systems

6. Không bắt buộc vận thăng điện với điều khiển từ xa to allow safe operation from a distance

High-quality explosion-proof hoists are designed and manufactured in compliance with international standards such as:

ATEX (Châu Âu)

IECEx (Global)

NEC/CEC (North America)

GB3836 (Trung Quốc)

Using certified explosion-proof equipment ensures that your operations meet legal and safety requirements, reducing the risk of costly incidents or downtime.

1. Tăng cường an toàn: Minimizes risk of ignition in volatile environments

2. High Reliability: Robust components built for continuous, heavy-duty use

3. Hiệu quả hoạt động: Reduces manual handling and improves workflow

4. Long-Term Cost Savings: Bền bỉ, low-maintenance design reduces downtime

When selecting an explosion-proof electric hoist for oil and gas operations, consider:

1. Load capacity requirements

2. Lift height and speed

3. Environmental conditions (nhiệt độ, độ ẩm, corrosion risk)

4. Power supply specifications

5. Required certifications for your region

Reputable manufacturers like Weihua, STAHL, Demag, and Kito offer explosion-proof hoists tailored to oil & gas applications.

Explosion-proof electric hoists are essential tools for ensuring safety, compliance, and efficiency in hazardous oil and gas environments. Whether you’re managing offshore rigs or petrochemical refineries, investing in certified explosion-proof lifting equipment is a strategic move that protects both your workforce and your assets.

Chúng tôi coi trọng phản hồi của bạn! Vui lòng hoàn thành biểu mẫu bên dưới để chúng tôi có thể điều chỉnh các dịch vụ của mình theo nhu cầu cụ thể của bạn.

Cụm xe nâng tời điện là một hệ thống vận chuyển có bánh xe được thiết kế để treo và ……

Là một thương hiệu hàng đầu trong ngành công nghiệp máy móc nâng Trung Quốc, Nhóm Woleua (Weihha) cho ……

Giới thiệu sản phẩm Palăng điện xe đẩy dầm đôi là loại xe nâng công suất lớn, công nghiệp……

Palăng điện treo tường Weihua được thiết kế dành cho người dùng công nghiệp cần……