Keeping your CM Lodestar electric hoist operating at peak performance is critical for safety, 效率, and productivity in any industrial setting. 随着时间的推移, components can wear out and require replacement. Sourcing the right CM Lodestar replacement parts is essential for maintaining the integrity and reliability of your equipment. This guide provides a comprehensive overview of the key replacement parts, their functions, and tips for selecting the right ones.

在线聊天Using genuine or high-quality certified replacement parts for your Lodestar hoist is not just a recommendation—it’s a necessity for several reasons:

Here are some of the most frequently replaced components for CM Lodestar chain hoists:

1. 负载链

The load chain is subject to constant use and wear. Signs you need a replacement include visible stretch, wear on the links, 腐蚀, 或损坏. Always replace with the correct grade and specification chain (例如。, 年级 80 或者 100) for your specific Lodestar model.

2. 上 & Lower Hooks

Hooks can become deformed, cracked, or have throats that have opened beyond allowable limits. Regular inspection is crucial, and any compromised hook must be replaced immediately.

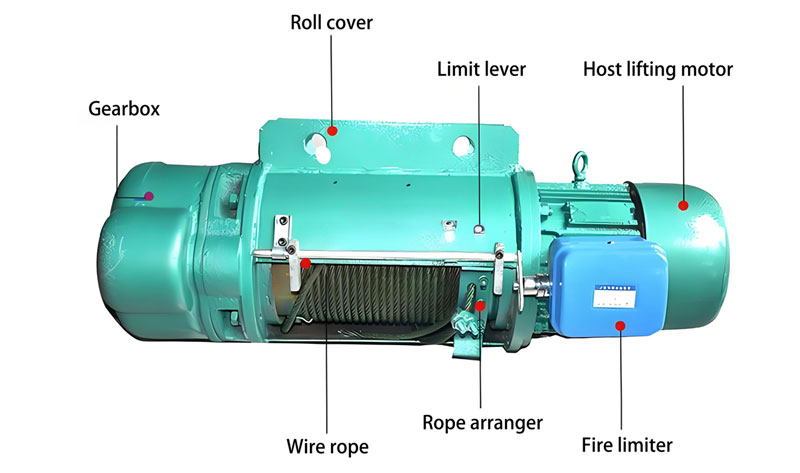

3. Brake Assembly

The brake is a critical safety component. If your hoist begins to “drift” or fails to hold a load, the brake assembly (including discs, springs, and magnets) may need service or replacement.

4. 发动机

Motors can fail due to electrical issues, overheating, or general wear. Symptoms include unusual noises, failure to start, or burning smells. Rebuilding or replacing the motor is a complex task best left to qualified technicians.

5. Control Pendants / Push Button Stations

The pendant controller receives significant physical abuse. Common issues include broken buttons, frayed cables, and faulty wiring. Replacement is often necessary for safe operation.

6. Contactors

Contactors are electrical relays that control the power to the motor. They can arc, weld shut, or fail over time, causing irregular operation. Replacing contactors often resolves electrical control issues.

7. Gears and Sprockets

Within the gearbox, mechanical gears and sprockets can wear down. Unusual grinding noises or jerky operation can indicate it’s time for inspection and potential replacement.

8. Lug Kits and Suspension Parts

These components connect the hoist to its mounting point. They must be inspected for cracks, 形变, or excessive wear to ensure a secure attachment.

始终将安全放在首位. The installation of critical components like brakes, 电机, and load chains should be performed by a qualified technician familiar with CM Lodestar hoists. After any major repair or part replacement, the hoist must be inspected and tested according to OSHA and ASME B30.16 standards before being returned to service.

Proactive maintenance and timely replacement of worn CM Lodestar electric hoist parts are key to maximizing uptime and ensuring a safe work environment. By identifying your hoist model, understanding the critical components, and sourcing quality parts from a reputable supplier, you can keep your Lodestar hoist running smoothly for years to come.

Need help finding the right part? Contact a certified hoist and rigging specialist today for expert advice on CM Lodestar replacement parts.

我们重视您的反馈! 请填写下面的表格,以便我们可以根据您的特定需求来量身定制服务.