在高风险的金属制造领域, 精度与蛮力的结合,最后期限迫在眉睫, 效率和安全不仅仅是目标——它们是盈利能力和生存的基石. 当谈到移动重型板材时, 定位复杂焊件, 或装载成品, 电动葫芦成为不可或缺的动力源. 不仅仅是一个便利, 这是一项战略投资,可以改变您的车间运营.

在线聊天日子已经一去不复返了 (或者他们应该是!) 每次提升都需要依靠繁琐的体力劳动或笨重的链条掉落. 电葫芦 带来一定程度的权力, 控制, 和手动方法根本无法比拟的重复性, 解决金属制造车间的核心挑战:

1. 控制吨位: 从厚钢板和结构梁到大型机械和成品制造, 金属很重. 电动葫芦可以轻松处理从几百磅到几吨的负载, 提升人员不安全或不可能的负载.

2. 精度放置: 焊接, 加工, 和装配要求精确度. 电动葫芦提供平稳, 受控提升和降低, 允许操作员将组件精确定位在需要的位置——这对于装配至关重要, 结盟, 和质量控制.

3. 提高生产力: 时间就是金钱. 电动葫芦大大减少了切割之间移动材料所花费的时间, 弯曲, 焊接, 和装配站. 手动方法需要几分钟的工作,电动葫芦只需几秒钟. 这可以释放熟练劳动力来完成增值任务.

4. 安全第一, 总是: 手动搬运重金属物体是车间受伤的主要原因——拉伤, 扭伤, 挤压伤, 更糟糕的是. 电动葫芦将工人从直接火线上转移. 强大的安全功能,例如过载保护, 紧急停止, 和故障安全制动器创造了一个显着更安全的工作环境, 减少事故和相关成本 (工人补偿金, 停机时间).

5. 操作员人体工程学: 减少身体压力不仅仅是为了安全; 这是为了防止疲劳. 使用电动葫芦的操作员工作更智能, 不难, 从而更好地集中注意力, 更少的错误, 和更高的士气.

6. 多功能性是关键: 电动葫芦无缝集成到各种商店设置中:

桥式起重机: 覆盖车间大面积的终极解决方案.

吉布起重机: 非常适合工作站特定的提升 (例如。, 靠近折弯机, 焊接单元, 或看到).

电动葫芦门式起重机: 非常适合户外庭院, 装货码头, 或没有永久架空支撑的区域.

单轨电车: 用于沿站点之间的固定路径移动负载.

并非所有起重机都适合金属制造的严苛环境. 考虑这些关键因素:

1. 容量: 确定您需要定期举起的最大重量. 不要忘记考虑起重附件的重量 (吊索, 磁铁, 吊架). 始终选择具有安全裕度的容量.

2. 提升高度: 测量起重机或吊臂下从最低吊钩点到所需最高提升点的距离.

3. 占空比 (CMAA级): 金属制造车间经常需要频繁起吊. 寻找具有更高工作周期的起重机 (例如。, CMAA D 级 – 重载或 E 级 – 重载) 承受持续使用而不会过早磨损. 更便宜, 轻型起重机不会持久.

4. 环境: 考虑暴露于:

热: 靠近焊接或切割区域? 确保葫芦具有足够的耐热性.

灰尘 & 碎片: 研磨和切割产生颗粒. 寻找具有良好入口保护的起重机 (IP等级) 或考虑封闭式起重机.

腐蚀性元素: 某些工艺或化学品可能需要不锈钢部件或特殊涂层.

5. 控制: 吊坠控制装置为标准配置. 寻找符合人体工程学的设计和功能,例如用于精细定位的变速控制. 无线电遥控器为操作员提供了更大的机动性和可视性, 对于大型升降机或尴尬的位置特别有用.

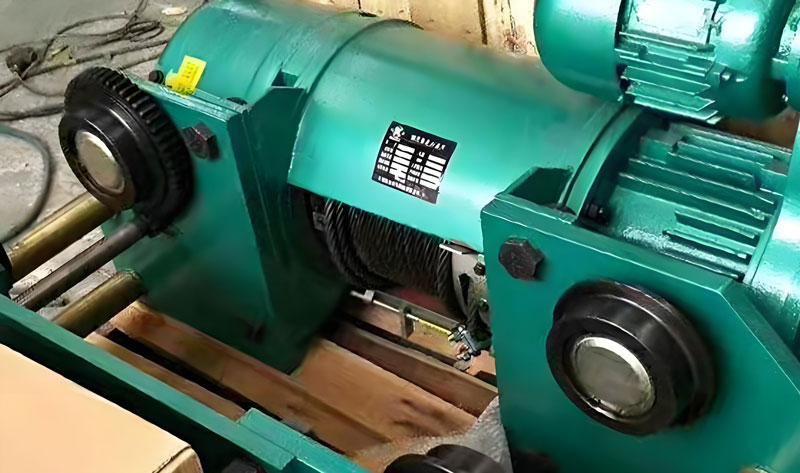

6. 提升类型: 钢丝绳葫芦通常为恶劣的工厂车间环境提供更高的容量和更高的耐用性. 环链葫芦可以更紧凑、更经济,适用于更轻的货物, 不太频繁的任务.

7. 安全功能: 不可协商. 必须包括过载限位开关, 上限/下限开关, 紧急停止, 热过载保护, 和故障安全制动.

8. 起重附件: 将起重机与您需要的工具相匹配: 板状磁铁, C型钩, 梁夹, 起重钳, 或专门的固定装置.

投资优质电动葫芦可带来实实在在的回报:

1. 降低人工成本: 用更少的人搬运更多的材料.

2. 更快的吞吐量: 通过商店更快地找到工作.

3. 损害最小化: 精确处理可防止对材料和成品造成代价高昂的损坏.

4. 降低受伤率 & 成本: 更安全的商店可以节省资金并保护您的员工.

5. 提高质量: 更好的定位带来更好的焊接和装配.

6. 增强车间容量: 手柄较大, 您之前可能拒绝的较重的项目.

电动葫芦不仅仅是一个设备; 它是您金属制造车间的力量倍增器. 它赋予您的员工力量, 保障他们的福祉, 加速生产, 并最终提高您的利润. 根据您的特定需求和环境仔细选择合适的葫芦, 您不仅仅是在搬运金属,您还将整个运营效率提升到一个新的水平, 安全, 和竞争力.

我们重视您的反馈! 请填写下面的表格,以便我们可以根据您的特定需求来量身定制服务.

电动葫芦门式起重机是一种高效、灵活的物料搬运设备……

高架电线绳吊顶代表起重技术的顶峰, 的……

为什么选择Weihua电动提升机进行发动机拆卸? 传统引擎吊头 (樱桃……

Weihua电动提升遥控器是工业LIF的核心控制组件……