该提升机的显着特点是其先进的变速控制系统. 与以固定速度运行的传统单速提升机不同, 经常出现不和谐的节奏, our technology allows operators to seamlessly adjust the lifting and lowering speed across a wide range:

- 1. Infinite Adjustability: Smoothly transition from ultra-slow creep speeds (inches per minute) for millimeter-precise positioning to higher speeds for efficient transportation across longer distances. Dial in the exact speed needed for the task at hand.

- 2. Precision Positioning: Achieve unparalleled accuracy when aligning heavy machinery, placing delicate components, or fitting parts into tight tolerances. Eliminate overshoot and the need for constant re-adjustment.

- 3. Gentle Load Handling: Protect fragile, 敏感的, or easily marred loads (例如。, finished surfaces, glass, precision equipment, unbalanced objects) by starting, 停止, and moving them smoothly without shock or sway.

- 4. 增强的安全性: Minimize load swing and instability. Controlled acceleration and deceleration drastically reduce the risk of sudden movements that could endanger personnel, damage surrounding equipment, or cause the load to become unstable. Operators have far greater command in critical situations.

- 5. Reduced Mechanical Stress: Eliminate the harsh jolts associated with direct-on-line starting and abrupt stopping. This significantly reduces wear and tear on gears, 刹车, wire rope/cable, and the hoist structure itself, extending service life and lowering maintenance costs.

Sophisticated Control Mechanisms

- 1. Advanced Pendant Control: Ergonomically designed pendant features intuitive controls, typically including:

- Separate Up/Down buttons with proportional control (press lightly for slow speed, press fully for higher speed).

- Dedicated slow-speed “creep” buttons for the highest precision.

- Potentially a speed selector dial for preset ranges.

- Emergency Stop button prominently placed.

- 2. Radio Remote Control Option: For enhanced safety and flexibility, operate the hoist wirelessly from the optimal vantage point, clear of the load path. Radio remotes offer the same precise variable speed functionality.

- 3. Integrated Frequency Inverter (VFD – Variable Frequency Drive): The heart of the system. This electronic controller precisely manages the power supplied to the hoist motor, varying its frequency and voltage to achieve smooth, stepless speed control and exceptional torque characteristics at low speeds.

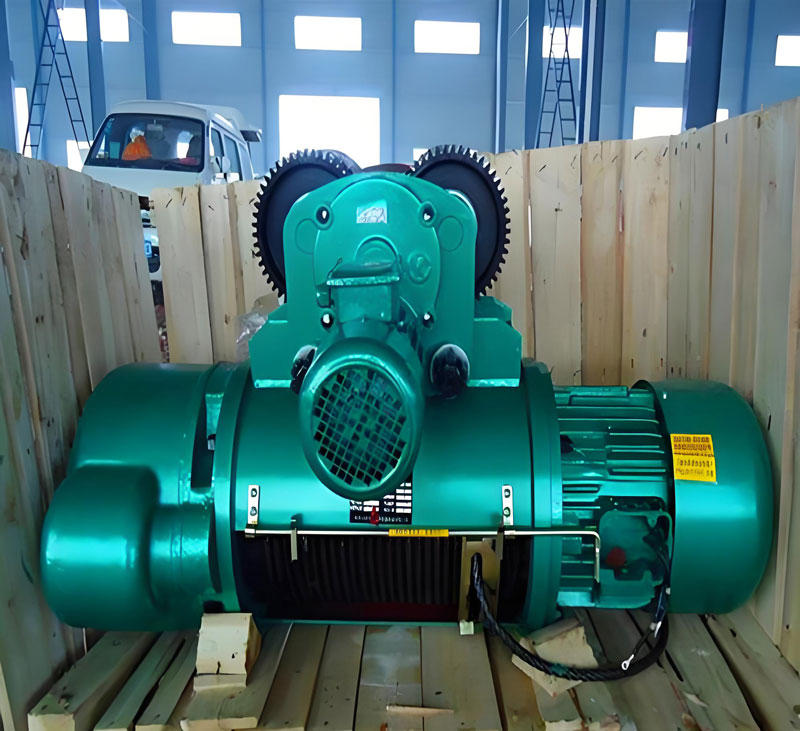

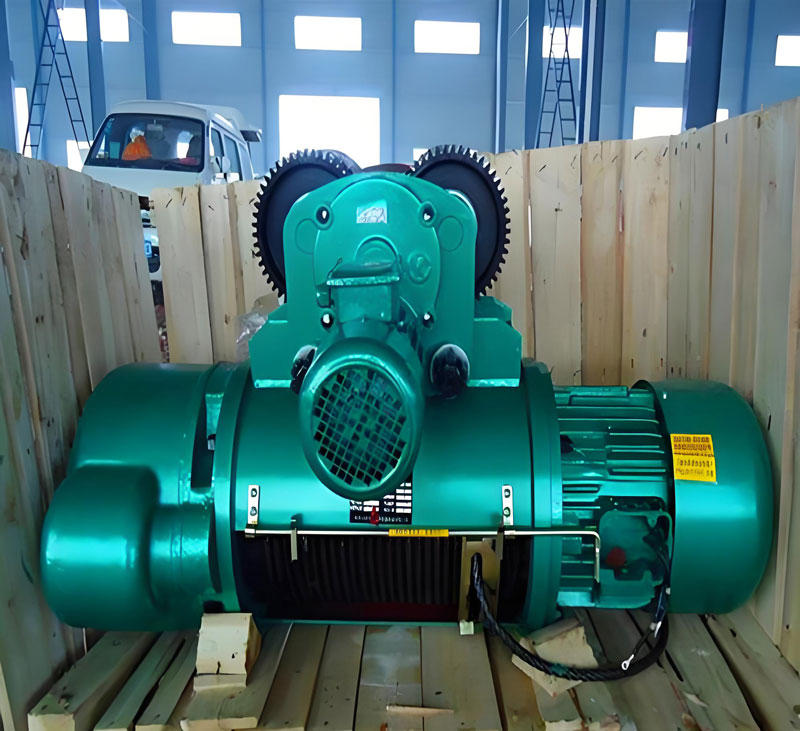

强大的结构 & 表现

-

高效电机: A specially designed AC or DC motor optimized for use with the VFD, providing reliable power, consistent torque across the speed range, and thermal protection.

-

Premium Lifting Medium: Available with high-strength, rotation-resistant Alloy Steel Wire Rope (standard for most capacities) or durable EPDM/PU Coated Steel Cable for enhanced flexibility and corrosion resistance. Capacities typically range from 250kg (0.25 吨) 到 10 Tons or more.

-

Lifting Speed Range: Wide operational spectrum, 例如。, 0.5 M/我 (Min) 到 8 M/我 (Max) (exact range depends on model and capacity).

-

职务等级: Engineered for Heavy Duty (有限元3m / H3) or Severe Duty (有限元4m / H4) cycles, ensuring reliability in continuous industrial use.

-

Gearing: Precision-machined, hardened helical or planetary gearing housed in a robust alloy casing, providing smooth power transmission and quiet operation.

-

Safety Critical Braking: Dual braking systems are standard:

-

限位开关: Automatic Upper and Lower Limit Switches prevent over-travel, protecting both the hoist mechanism and the load.

-

过载保护: Integrated overload clutch or electronic monitoring system safeguards the hoist against accidental overloading.

-

建造: Durable steel housing, often with corrosion-resistant finishes (画, galvanization) suitable for industrial environments. Sealed components protect against dust and moisture ingress (IP54 / IP65 ratings common).

Electric Hoist with Variable Speed Control Versatile Applications

This hoist excels wherever control and precision are critical:

- 1. 精密装配线: 定位引擎, turbines, large machinery components.

- 2. 制造业 & 制造: Handling sheet metal, 模具, 死了, weldments.

- 3. 仓库 & 后勤: Carefully placing fragile goods, positioning loads onto racks, loading/unloading sensitive equipment.

- 4. 维护 & Repair Shops: Installing/removing heavy equipment parts (例如。, pumps, 电机, 压力机) safely and accurately.

- 5. 航天 & 汽车: Handling delicate aircraft components or vehicle bodies.

- 6. Stage & Entertainment: Smoothly moving scenery, lighting rigs, and props.

- 7. Foundries & Forges: Handling hot materials with controlled movements.

- 8. Research Labs & 洁净室: Precise placement of sensitive instrumentation.

Key Benefits Summary

- 1. Unparalleled Precision: Achieve exact positioning effortlessly.

- 2. 增强的安全性: Minimize load swing, reduce operator risk, ensure controlled stops.

- 3. Superior Load Protection: Handle fragile, unbalanced, or sensitive loads with confidence.

- 4. 提高生产力: Work faster and more efficiently with optimized speeds.

- 5. 降低维护成本: Less mechanical stress extends component life.

- 6. Operator Comfort & 控制: Intuitive operation reduces fatigue and improves results.

- 7. 多功能性: Adapt to a vast array of demanding lifting tasks.

Invest in Control, Invest in Safety, Invest in Efficiency.

Our Electric Hoist with Variable Speed Control represents the pinnacle of intelligent lifting technology. It transforms challenging lifts into smooth, 受控, and safe operations. Experience the difference precision control makes in productivity, 安全, and load integrity.

Contact us today to discuss your specific requirements and find the perfect variable speed hoist solution for your application!