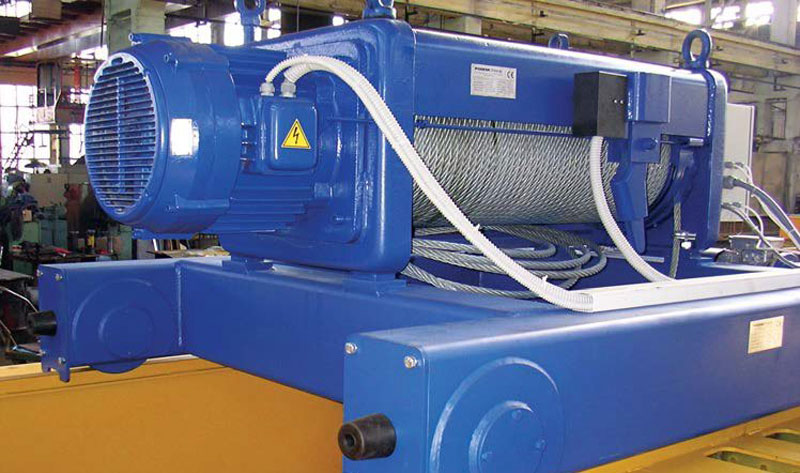

Foundries are the beating heart of metalcasting, environments where raw materials are transformed under intense heat. Molten metal, radiant heat, sparks, and dust create one of the most demanding industrial settings imaginable. Standard lifting equipment simply won't survive here. That's where the specialized Foundry Electric Hoist with Heat Resistant Features becomes not just a tool, but a critical safety and productivity asset.

在线聊天Ordinary 电葫芦 is designed for ambient temperatures. 将它们暴露在熔炉附近的极热环境中, 钢包, 或新浇铸件, 你冒着风险:

1. Insulation Breakdown: Wiring and motor insulation can melt or crack, leading to short circuits, electrical fires, and catastrophic failure.

2. Lubricant Failure: Standard greases and oils liquefy or carbonize, causing bearings to seize and gears to grind, resulting in rapid wear and potential jamming.

3. Structural Weakening: Prolonged heat exposure can anneal critical steel components (like the load chain or hook), reducing their strength and creating a dangerous risk of breakage under load.

4. Control System Malfunction: Electronic components in pendant controls or variable frequency drives (VFDs) are highly sensitive to heat and can fail unpredictably.

5. Premature Wear: Dust and abrasive particles accelerated by heat quickly degrade unprotected mechanisms.

A true foundry-duty electric hoist incorporates a suite of features specifically designed to combat these harsh conditions:

1. High-Temperature Insulation (H级): Motors and wiring systems are built using Class H insulation materials, rated to withstand continuous operating temperatures up to 180℃ (356°F). This is significantly higher than the Class B (130℃) or Class F (155℃) found in standard hoists.

2. Heat-Resistant Lubrication: Special high-temperature greases and oils are used throughout the gearbox, 轴承, and load chain. These lubricants maintain their viscosity and protective properties even under intense radiant heat, ensuring smooth operation and preventing seizure.

3. Thermal Protective Barriers: Critical components like the motor and gearbox are often equipped with additional shielding or thermal barriers. This can include heat-resistant shrouds or reflective plates to deflect radiant heat away from sensitive parts.

4. Protected Electrical Systems: Conduits, junction boxes, and pendant stations are designed with robust, heat-resistant materials and gaskets to keep out dust and hot air. Control systems may be housed in cooled enclosures or located remotely.

5. Heat-Treated Load Path Components: The hook, load chain (或钢丝绳), and sheaves are manufactured from high-grade alloys and undergo specific heat treatments to maintain their strength and toughness at elevated temperatures. Look for hoists rated for higher temperature service (例如。, hooks rated for 300°C+/572°F+ intermittent exposure).

6. Enhanced Sealing: Superior sealing protects internal mechanisms from abrasive foundry dust (sand, shot blast, ETC。) and moisture, which can combine with heat to accelerate corrosion and wear.

7. 强大的结构: Overall build quality is paramount, using durable materials and designs to withstand thermal cycling (repeated heating and cooling) without warping or cracking.

Investing in a heat-resistant foundry electric hoist delivers significant operational advantages:

增强的安全性: Dramatically reduces the risk of catastrophic hoist failure due to heat, protecting personnel, 设备, and valuable castings from potentially devastating accidents.

Increased Uptime & 生产率: Minimizes unplanned downtime caused by heat-related breakdowns, keeping your production line moving.

降低维护成本: Heat-resistant components and lubricants last significantly longer in the foundry environment, lowering maintenance frequency and replacement part costs.

Extended Service Life: Designed for the environment, these hoists offer a much longer operational lifespan than standard models, providing a better return on investment.

遵守: Helps meet stringent safety regulations (职业安全与健康管理局, ETC。) and industry standards for operating equipment in high-heat industrial zones.

When selecting a heat-resistant electric hoist:

1. Specify the Temperature Range: Clearly define the ambient temperature near the hoist’s operating location and the peak temperatures it might be exposed to (例如。, radiant heat from a nearby ladle).

2. 占空比: Consider how frequently and intensively the hoist will be used in the heat.

3. 提升能力 & 速度: Ensure it meets your specific load and cycle time requirements.

4. 防护等级: Look for appropriate IP (入学保护) ratings against dust and moisture, often IP54 or IP65 for foundries.

5. Reputable Manufacturer: Choose a supplier with proven experience in designing and manufacturing foundry-duty lifting equipment. 认证证书 (ISO, ETC。) are important.

6. 服务 & 支持: Ensure parts availability and technical support from the manufacturer or distributor familiar with foundry challenges.

In the unforgiving environment of a foundry, a standard electric hoist is a liability waiting to happen. A purpose-built Foundry Electric Hoist with Heat Resistant Features is an essential investment in safety, 可靠性, and operational efficiency. By incorporating specialized insulation, lubrication, shielding, and robust construction, these hoists are engineered to endure the heat, 灰尘, and demands of molten metal handling. Don’t compromise on lifting safety in your foundry – equip your operation with the heat-resistant power it needs to thrive.

我们重视您的反馈! 请填写下面的表格,以便我们可以根据您的特定需求来量身定制服务.

VEVOR电动葫芦配备耐用的铜电机和先进的散热……

10 吨电链葫芦钥匙功能 1. 高起重能力: 支持最大值……

15 吨钢丝绳电动葫芦主要特点 & 好处 1. 卓越的起重能力……

作为核心产品小型电动葫芦, 1/2 吨环链电动葫芦适用于……