电动葫芦起升失败主要由五大因素造成, 包括: 电源, 制动系统, 电机和传动装置故障, 电气控制, 及限位保护装置. 解决电动葫芦无法升降的问题, 这些问题有必要一一排查, 确定问题后再针对性解决.

在线聊天你按下了你的按钮 电葫芦, 却什么也没发生. 没有令人安心的嗡嗡声, 没有向上或向下移动. 停滞的起重机不仅不方便; 它会降低生产力并可能预示潜在的安全隐患. 在恐慌来临之前, 让我们系统地诊断您的电动葫芦可能拒绝移动的原因.

断开电源: 在检查任何东西之前, 在主断路器处将葫芦与其电源隔离. 上锁/挂牌程序至关重要.

固定负载: 如果负载被悬挂, 在开始任何故障排除之前确保它得到安全支持或阻止. 切勿在无支撑的负载下工作.

电源问题 (最常见的嫌疑人):

无电源: 首先检查明显的! 主断路开关是否打开? 断路器是否跳闸或保险丝熔断? 验证电源已到达葫芦所插入的插座/插座 (如果适用的话). 提升机主端子的测试电压 (连接期间安全断开电源, 然后重新申请测试).

缺相 (3-相位提升机): 如果缺少一相, 电机无法启动. 检查保险丝, 接触器, 和接线完整性. 聆听电机发出的巨大嗡嗡声——这是单相的典型标志.

低电压: 电压过低会导致电机无法产生足够的扭矩来启动. 如果可能的话检查负载电压.

电源线/插头故障: 检查是否有损坏, 削减, 或烧伤. 测试连续性.

控制电路故障:

吊坠/遥控器有缺陷: 按钮棒, 电线内部断裂, 或连接腐蚀. 尝试使用已知良好的吊坠(如果有). 检查电源线是否有损坏.

控制变压器故障: 为控制电路提供较低的电压. 如果失败, 控制按钮不执行任何操作.

接触器或继电器卡住/松动: 这些电磁开关激活电机. 他们可以焊接关闭, 拉不进去, 或触点被腐蚀而无法完成电路. 操作控件时聆听明显的“咔哒”声.

限位开关已激活: 提升机设有上下限位开关,防止超程. 如果卡在“跳闸”位置或发生故障, 它将阻止该方向的操作. 检查起重葫芦是否与限位开关执行器物理接触. 有时需要手动重置.

机械卡纸 & 重载:

物理障碍: 检查整个路径. 是否负载, 钩, 或链条/绳子被某物缠住? 齿轮内是否有杂物卡住, 链轮, 或鼓?

链条脱轨 (环链葫芦): 如果链条从链轮上跳下来, 运动是不可能的. 需要断电并小心重新安装.

严重超载: 超过提升机的额定容量可能会导致电机堵转或过载保护立即启动. 检查负载重量. 聆听没有运动的电机嗡嗡声——这是过载的迹象.

制动器磨损或卡住: 必须松开制动器才能移动. 如果因磨损而被扣押, 污染, 或损坏, 电机无法转动. 经常不转动且嗡嗡作响的电机表明制动器卡住了.

绑定齿轮或轴承: 缺乏润滑, 污染, 或损坏可能导致内部机械部件结合, 防止旋转. 聆听是否有异常的研磨或刮擦噪音.

电机问题:

电机过热: 电机内部的热过载保护可能因过度使用而跳闸, 超载, 或通风不良. 在尝试重新启动之前,请留出足够的时间让电机完全冷却.

内部电机故障: 绕组可能会短路, 倦怠, 或连接失败. 这通常需要专业维修或更换电机. 迹象包括烧焦的气味, 即使没有负载也会过热, 或在启动时立即跳闸断路器.

接线故障:

连接松动: 检查控制面板中所有端子连接, 在电机处, 以及接触器/继电器. 随着时间的推移,振动会使它们松动.

内部线路损坏: 啮齿动物损害, 压紧的电线, 或内部腐蚀可能会破坏电路. 这个需要仔细检查, 通常由合格的技术人员进行.

观察: 电机是否有嗡嗡声? 控制器上的灯是否亮起? 您是否听到接触器喀哒声?

检查电源: 系统地验证从电源到葫芦主端子的电源.

检查控制装置: 测试吊坠/遥控器 (目视检查电线). 监听控制接触器的喀哒声.

寻找明显的机械问题: 障碍物, 卡住的链条/绳子, 限位开关触点?

考虑最近发生的事件: 是否超载了? 停止前过度使用? 暴露于湿气/灰尘?

如果问题涉及内部电机绕组或复杂的控制电路.

如果您怀疑有严重的机械损坏 (齿轮, 轴承, 刹车总成).

如果葫芦出现过热或烧焦气味的迹象.

如果您不合格或不擅长电气/机械系统工作.

始终将安全置于优先权之上.

根据制造商的时间表进行定期预防性维护是防止意外停机的最佳方法. 这包括润滑, 机械部件检查 (链条, 绳索, 钩子, 刹车), 电气连接检查, 以及控制装置和限位开关的功能测试.

通过有条不紊地解决这些潜在原因, 您通常可以识别并解决阻止电动葫芦提升或降低的问题, 让您的运营安全高效地重回正轨. 记住: 当有疑问时, 关闭它并请专家来!

我们重视您的反馈! 请填写下面的表格,以便我们可以根据您的特定需求来量身定制服务.

传统的电动提升机需要在钩高的高高之间重大的净空……

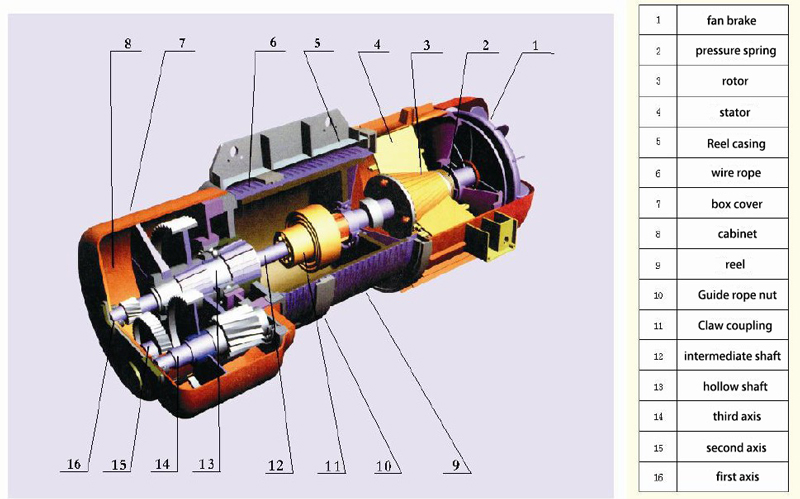

产品概述 FEM标准钢丝绳电动葫芦是一种高性能起重设备……

这 1 吨环链电动葫芦非常适合中小型起重任务,因为......

这 3 吨环链电动葫芦是卫华G公司自主研发的中型起重设备……