魏哈, 中国领先的起重机和葫芦制造商, 提供专为冶金环境设计的电动葫芦, 提供增强的耐热性, 安全机制, 和运行可靠性.

卫华冶金用电动葫芦专为在恶劣环境下吊运熔融金属和其他高温物料而设计. 提升机系统符合GB/T 3811-2008, JB/T 9008.1-2004, 和其他国际标准, 确保耐用性, 安全, 和精确的控制.

耐高温: 配备隔热板和耐热电线, 组件可耐受高达 300°C 的温度.

双制动系统: 采用机械和电磁双制动结构,提高操作安全性.

过载保护: 智能监控,过载自动关闭, 防止事故和设备损坏.

精准控制: 变频驱动 (VFD) 用于熔融材料的平稳提升和定位.

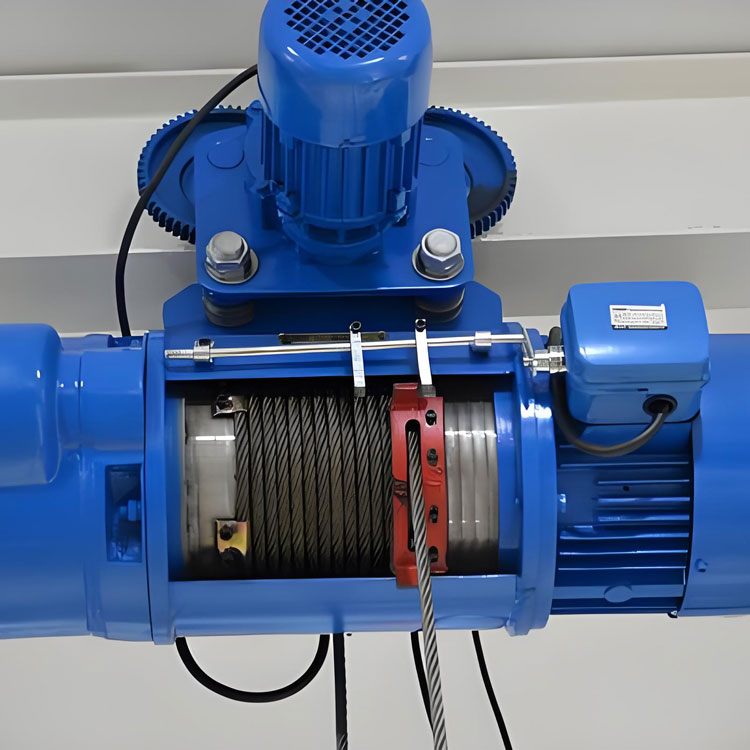

重型设计: 高强度钢丝绳, 隔热垫片, 和H级绝缘电机.

提供防爆选项: 适用于有易燃气体或粉尘的环境.

安全冗余: 配备限位开关, 上下位报警, 及温度监控装置.

| 模型 | 负载能力 | 提升高度 | 提升速度 | 行进速度 | 工作职责 | 电源 | 环境温度 | 绝缘班 |

| WH-MH5T | 5 吨 | 6–12 m | 8 M/我 (VFD) | 20 M/我 | M6 | 3博士学位, 380v, 50赫兹 | -20°C 至 300°C | H级 |

| WH-MH10T | 10 吨 | 6–16 m | 7 M/我 (VFD) | 20 M/我 | M6 | 3博士学位, 380v, 50赫兹 | -20°C 至 300°C | H级 |

| WH-MH15T | 15 吨 | 6–20 m | 6 M/我 (VFD) | 20 M/我 | M7 | 3博士学位, 380v, 50赫兹 | -20°C 至 300°C | H级 |

| WH-MH20T (可自定义) | 20 吨 | 6–24 m | 5 M/我 (VFD) | 20 M/我 | M7 | 3博士学位, 380v, 50赫兹 | -20°C 至 300°C | H级 |

笔记: 可根据要求提供定制规格, 包括防爆功能, 无线遥控, 和更高的工作职责分类.

可选的附加组件和定制

1. 无线遥控或半自动控制系统

2. 防爆电动葫芦 或隔爆型号 (防爆 IIBT4, Exd IICT4 区域 1 & 区 2)

3. 与桥式起重机集成, 钢包起重机, 和自动化系统

4. 负载限制器, 电子称重, 和数据记录器

卫华冶金电动葫芦是卫华数十年研发的成果&D、实践经验, 尤其是与大型钢铁企业的合作. 主要设计创新包括:

1. 隔热系统: 多层绝缘系统可保护电气和机械部件免受辐射热影响. 钢丝绳卷筒, 钩块, 电机外壳采用耐火材料隔热.

2. H级或更高绝缘电机: H级绝缘电机 (耐受高达 180°C), 以及可选的水冷或强制风冷设计,可实现连续工作.

3. 特种合金钢丝绳: 热处理, 耐腐蚀钢丝绳可延长高温条件下的使用寿命.

4. 密封齿轮箱和轴承: 全封闭式 IP55–IP65 级齿轮箱和自润滑轴承即使在多尘和潮湿的工厂条件下也能延长使用寿命并最大限度地减少维护.

5. 可编程逻辑控制器 (可编程逻辑控制器) 选项: 起重载荷智能监控, 温度, 制动情况, 和使用周期. 实现预测性维护并最大限度地减少停机时间.

卫华交付 12 POSCO板坯连铸线10T冶金提升机多套. 这些提升机运行于 95% 将热监控系统集成到工厂 MES 中的工作周期 (制造执行系统).

卫华为定制电动葫芦提供耐腐蚀涂层和防火花部件, 对于在黄金提纯炉环境中处理熔融合金和精矿至关重要.

紧凑设计7.5T 低净空环链电动葫芦 手推车可在严格的车间限制下实现高效运行.

卫华冶金电动葫芦已广泛应用于钢厂, 铸造厂, 铝精炼厂, 及多个国家的有色金属行业. 它们的可靠性和坚固的制造质量使它们成为诸如以下操作的理想选择::

1. 在高炉中处理铁水

2. 连铸机中的提升钢包

3. 将原材料送入转换器

4. 移动钢锭, 板, 和线圈

超过 35 多年起重机和葫芦制造经验

ISO, CE, 并通过SGS认证

全球服务网络和支持

在高温和重负载应用中经过验证的可靠性

卫华冶金电动葫芦融合创新, 坚固的工程, 和安全性——使其成为钢厂的理想选择, 冶炼厂, 和世界各地的铸造厂. 提供量身定制的解决方案, 卫华赋能金属行业即使在最恶劣的环境下也能高效运行.

我们重视您的反馈! 请填写下面的表格,以便我们可以根据您的特定需求来量身定制服务.

The Weihua 1 TON电链葫芦与遥控器结合了值得信赖的工程, …………

高架电线绳吊顶代表起重技术的顶峰, 的……

产品概述 FEM标准钢丝绳电动葫芦是一种高性能起重设备……

Weihua Jib Crane Electric Hooist结合了臂臂的灵活性和动力……