寻找可靠的 车间电动葫芦 运营? Weihua’s 电葫芦 是您提高生产力的理想选择, 安全, 以及在任何车间环境中的便利性.

| 范围 | WH-EH系列 (0.5 – 5 t) | WH-EHX系列 (5 – 20 t) | 笔记 |

| 额定容量 | 0.5 t, 1 t, 2 t, 3 t, 5 t | 5 t, 7.5 t, 10 t, 15 t, 20 t | 根据车间负荷要求选择 |

| 标准举升高度 | 6 米, 9 米, 12 米 | 6 米, 9 米, 12 米 | 最长可延长 24 米 |

| 提升速度 | 8 米/我的 (单身的), 4 / 8 米/I (两速) | 4 / 8 米/I (两速) | EH 上有两速可选; EHX 标准 |

| 电机动力 | 1.5 kW – 7.5 kW | 15 kW – 37 kW | TEFC, F级绝缘, S3 25% 责任 |

| 变速箱速比 | 28 : 1 | 40 : 1 | 斜齿轮, >94% 效率 |

| 链条规格 | Ø7 × 21 mm 合金钢 DIN 6,806 | Ø10 × 30 mm 合金钢 DIN 6,806 | 热处理, 珠光体表面处理 |

| 挂钩类型 | 锻造, 360°-可旋转, 安全闩锁 | 锻造, 360°-可旋转, 安全闩锁 | 标准挂钩开口: 25 – 60 mm 取决于容量 |

| 手推车轴距 | 70 – 160 mm (齿轮传动) | 100 – 200 mm (齿轮传动) | 提供普通和动力手推车选项 |

| 制动类型 | 电磁盘, 弹簧应用 | 电磁盘, 弹簧应用 | 断电时自动重新接通 |

| 控制电压 | 48 V DC 吊坠; 220 V / 380 V交流电源 | 48 V DC 吊坠; 380 V / 415 V交流电源 | IP65期间; 无线电遥控可选 |

| 环境温度 | –20 °C … +40 °C | –20 °C … +40 °C | 湿度高达 90% 非冷凝 |

| 保护课 | IP54 (标准) / IP65 (选修的) | IP54 (标准) / IP65 (选修的) | 电子设备密封防尘、防潮 |

| 噪音水平 | < 75 分贝(一个) | < 78 分贝(一个) | 空载情况下1米距离处测量 |

| 净重 | 120 – 350 kg | 500 – 1,200 kg | 因容量而异, 手推车, 和选项 |

| 标准 & 证书 | 在 14492-2, ISO 13849, CE | 在 14492-2, ISO 13849, CE | 可提供SGS工厂检验 |

| 保修单 | 24 月 (电机/变速箱), 12 月零件 | 24 月 (电机/变速箱), 12 月零件 | 提供扩展和现场服务包 |

笔记: 如果您需要定制参数集,请随时告诉我们, CAD图纸, 或针对您的特定车间起重机布局的集成支持.

型号范围

WH-EH系列: 0.5 t – 5 t 起重能力

WH-EHX系列: 5 t – 20 t重型车间提升机

提升高度: 标准高度可达 12米; 最长可延长 24 米

提升速度: 单速 (8 米/我的) 或两速 (4 + 8 米/我) 选项

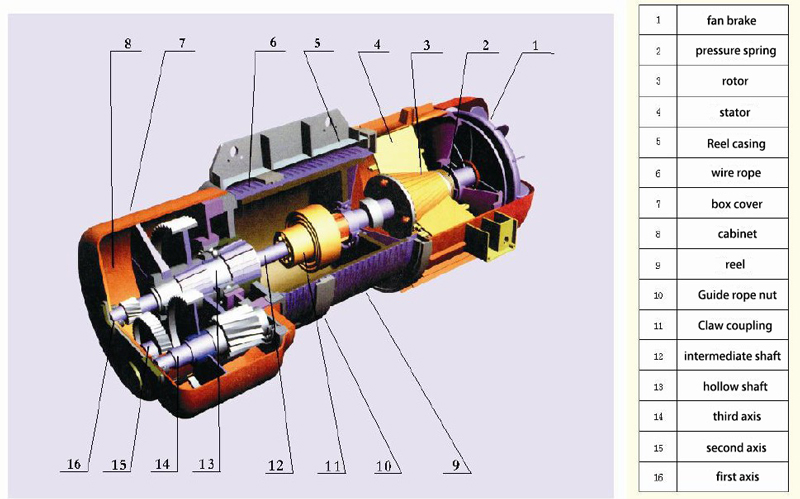

葫芦架:

焊接式, 高强度钢板框架.

模块化设计,快速访问,易于维护.

负载链 & 钩:

合金钢链条, 经过热处理以获得额外的耐磨性.

360° 可旋转锻造钩,带安全闩锁.

手推车选项:

用于直行梁的普通小车

轴距可调的齿轮手推车 (70–160 mm)

用于自动化起重机系统的动力小车

发动机:

全封闭风扇冷却 (TEFC) 发动机,

绝缘等级F, 工作等级 S3 25%.

变速箱:

斜齿轮传动

经过硬化和磨削的齿轮齿,噪音低 (<75 分贝) 和高效率 (>94%)

过载保护

电子负载限制器可防止提升超过额定容量.

限位开关

上下机械限位开关,防止超程.

刹车系统

电磁弹簧盘式制动器; 断电时自动重新接通.

紧急停止

红色的, 悬垂控制器上的蘑菇头急停按钮.

吊坠控制

IP65防水外壳, 人体工学设计, 4 米电缆 (可定制长度).

无线电遥控 (选修的)

8-按钮发射器; 范围可达 50米; 电池状态指示灯.

安装

可直接悬挂在横梁上或连接到手推车上.

快速连接支架和可调节夹具简化了安装.

例行检查

日常的: 目视链检查, 钩锁检查, 制动功能测试.

每月: 链条润滑, 电机温度检查, 变速箱油位.

每年: 由经过认证的技术人员进行全面检查, 负载测试在 125% 额定容量.

符合:

EN 14492-2 (欧洲起重机安全标准)

ISO 13849 (控制系统的安全相关部分)

CE标志, 可根据要求提供 SGS 工厂检验证书

环境评级: IP54 (标准), IP65 (选修的)

防碰撞缓冲器: 用于行程末端缓冲的橡胶缓冲器

称重模块: 吊坠上实时显示重量

变频驱动 (VFD): 无级调速, 软启动/停止

负载定位激光: 精确的目标指针可重复提升

定制油漆 & 品牌推广: RAL配色及标志丝印

保修单: 24 电机和变速箱的月数; 12 其他部分的月数

备件: 5-年保证可用性

技术支援: 24/7 热线; 通过内置物联网模块进行远程诊断 (选修的)

现场培训: 操作员和维护人员培训包

卫华车间电动葫芦广泛应用于设备维护, 物料搬运, 机器零件组装, 等车间吊装场景. 可安装在单梁起重机上, 吉布起重机, 或固定悬挂点, 提供灵活便捷的起重解决方案.

拥有数十年起重设备行业经验, 卫华保证高品质产品, 及时交货, 和优秀的售后支持. 我们的车间电动葫芦以其卓越的性能和可靠性受到全球成千上万客户的信赖.

我们重视您的反馈! 请填写下面的表格,以便我们可以根据您的特定需求来量身定制服务.