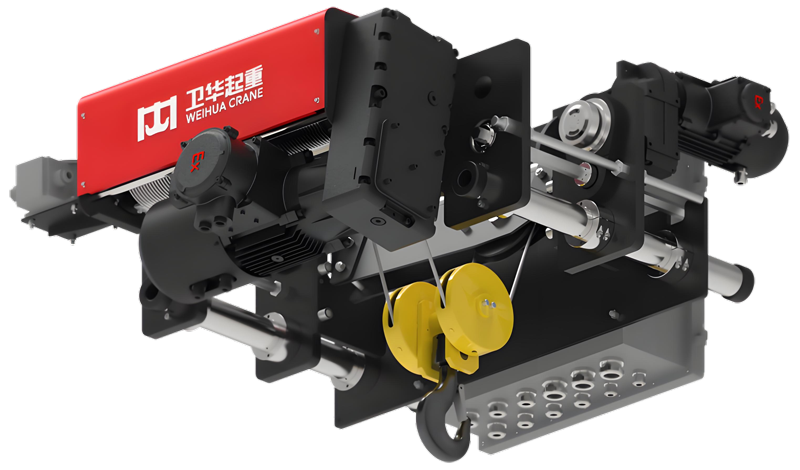

The explosion proof electric hoist is an explosion proof lifting equipment designed and manufactured by Weihua to the latest explosion proof standards. The exposed explosion proof parts of the explosion proof electric hoist are made of special non-sparking materials, and the explosion proof performance is safe and reliable. Explosion proof electric hoist can be used in high-risk, flammable and explosive places

The explosion proof electric hoist produced by Weihua Group has passed the international ATEX/IECEx explosion proof certification and is specially designed for Zone 1/Zone 2 危险区域, providing absolute safe operation guarantee with zero sparks and low surface temperature. Explosion proof electric hoists are often used in hazardous areas where flammable and explosive gases/dust exist, such as petrochemical industry, natural gas mining, mining operations, and pharmaceutical workshops. Since sparks or high temperatures from ordinary electric hoists may cause catastrophic accidents, explosion proof electric hoists are required.

防爆电动葫芦

Military-grade explosion proof design to eliminate potential safety hazards

智能控制, precise and efficient

Extreme environmental adaptability and durability

防爆电动葫芦

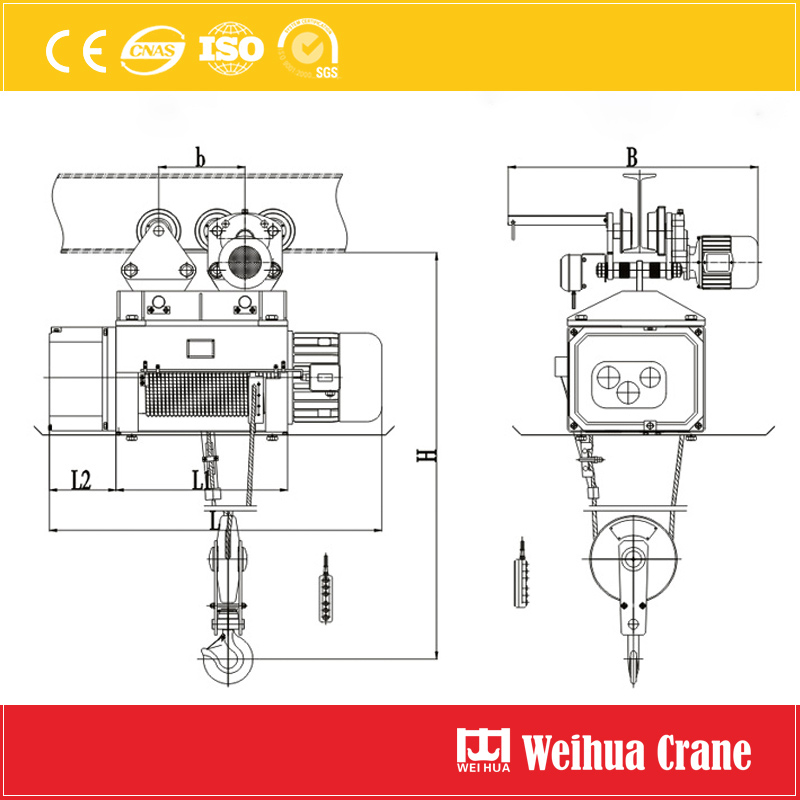

| 项目 | 参数范围 |

| 容量 | 0.5 吨, 1 吨, 2 吨, 3 吨, 5 吨, 10 吨, 30 吨, 50 吨, 100 吨 (customization is supported) |

| 提升高度 | 3m~30m (标准), can be customized to 100m |

| 提升速度 | 单速: 8M/我; 双速: 8/0.8M/我; 变频调速: 0.1-10M/我 |

| Travelling Speed | 10-20M/我 (ground hand push) / 20-30M/我 (electric operation) |

| 职务等级 | FEM 1Am ~ 2m / ISO M3 ~ M5 |

| 电源 | 380V/50Hz 三相交流 (可选220V/60Hz) |

防爆认证

Explosion-proof component configuration

Safety redundant design

防爆电动葫芦

| Part | Technical specifications |

| 钢丝绳 | Anti-rotation type 6×36WS+IWR, galvanized/stainless steel (anti-corrosion option) |

| 钩 | Forged from alloy steel, safety tongue + rotation lock, load tested at 1.25 times |

| Track adaptation | 工字钢 (160~400mm belly width)/KBK light track/customized steel |

| Shell coating | Epoxy resin powder coating (thickness ≥120μm), salt spray resistance 2000h |

| 行业 | Application cases | Explosion-proof requirements |

| Petrochemical industry | Refinery reactor hoisting and tank area equipment maintenance | Protection against Class IIA/IIB/IIC gas explosions |

| Underground coal mine | Installation of shearer components and improvement of ventilation equipment | Methane gas + dust double explosion-proof |

| Grain processing | Flour silo conveying system, starch production line hoisting | Dust explosion protection (ST3 level) |

| 航天 | Rocket fuel storage tank handling, hangar maintenance equipment lifting | Anti-hydrogen/kerosene aerosol explosion |

| New energy manufacturing | Lithium battery electrode material handling, hydrogen energy battery pack assembly | Anti-metal dust + hydrogen mixed explosion risk |

防爆电动葫芦

Explosion proof electric hoist manufacturing process

Explosion proof electric hoist manufacturer

Get your exclusive plan now

📞 Whatsapp: +86 13613816589

📧 Official email: aiden@craneweihua.com

🌐 Online consultation: Click to contact the explosion proof electric hoist

Homepage: https://www.weihualargecrane.com

我们重视您的反馈! 请填写下面的表格,以便我们可以根据您的特定需求来量身定制服务.

重型电动葫芦主要特点 ✅ 高起重能力:卫华重型电动…

The Weihua 1 TON电链葫芦与遥控器结合了值得信赖的工程, …………

Weihua电动提升遥控器是工业LIF的核心控制组件……

在动力设备安装中, 电缆制造和重物输送, 那个……